Are zero prototyping and software-driven development the end of vehicle testing?

As vehicles become increasingly defined by software, the ways we design, engineer and validate cars are undergoing a seismic shift. With simulation, digital twins, and AI-driven insights, virtual testing is gaining ground – and even the bold vision of zero prototyping is on the table. We’ve asked Bruno Massa, Vice-President of Testing and Smart Vehicle Technologies, what his take is on zero prototyping and the impact of software-driven development.

From mechanics to code

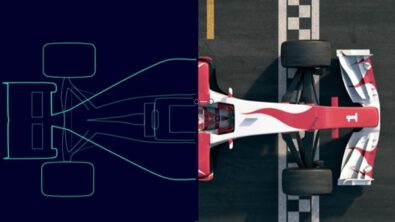

The automotive industry is undergoing a profound transformation – one that’s not driven by horsepower or hardware, but by lines of code. As vehicles evolve into sophisticated, software-defined systems, the center of gravity in engineering is shifting from mechanical design to software development. This change is not just technological; it’s strategic.

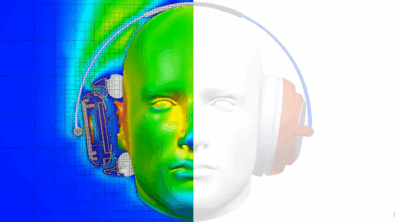

The benefits are clear: modular architectures and agile development platforms allow automakers to iterate faster, reduce costs, and deliver smarter, safer, and more personalized driving experiences. Digital twins and simulation environments enable engineers to model complex interactions before a single prototype is built, accelerating time-to-market and reducing risk.

Is zero prototyping the future?

With simulation and digital twins, it’s now possible to replace physical testing with software-based testing. Different components can be virtually analyzed alongside each other to refine and optimize designs well before prototypes are created. Some people are even talking about moving towards zero prototyping.

Can virtual environments truly capture the complexity of real-world conditions? Is the goal of ‘zero prototyping’ realistic or just an ambitious ideal?

What is the role of vehicle testing in this new landscape?

We interviewed Bruno Massa, Vice President of Testing and Smart Vehicle Technologies at Siemens, about the role of testing in today’s landscape. He provided his insights on adapting to zero prototypes by using an integrated simulation and testing approach for vehicle development, aiming to ensure the quality, reliability, and performance of software-driven vehicles.

The future of automotive engineering will depend on how well we integrate simulation, AI, and physical validation into a cohesive, continuous development loop.

Bruno Massa, Vice-President of Testing and Smart Vehicle Technologies at Siemens

Executive take: four questions on the future of vehicle testing

In four short videos, Massa provides valuable insights into how Simcenter Testing Solutions has evolved over recent years and the changes you can expect to see soon. He covers topics such as:

- Fundamental ways testing teams can adapt to meet the challenges of software-defined vehicles

- How testing assures a higher simulation accuracy

- How test and simulation are combined to analyze complex behavior

- The role that testing will play as simulation technologies continue to improve

- How artificial intelligence helps improve testing solutions

- Why testing is essential in delivering reliable AI-based predictions

- How data engineering and multidisciplinary competencies will shape the future of simulation and testing

- And more

What our customers say about our vehicle testing solutions

Our customers consistently recognize the value of our vehicle testing solutions, citing optimized NVH behavior, enhanced durability testing, faster simulation cycles, and seamless integration between test and simulation as key benefits. From reducing component simulation time by 80% to improving product robustness earlier in development, the impact is real and measurable. You can browse through our vehicle testing references here.

What’s your perspective?

As vehicle testing evolves, so must our thinking… Bruno Massa shared his view on zero prototyping and the impact of software-driven development on vehicle testing. These questions are just the beginning – how would you answer them? Join the conversation below.

More info

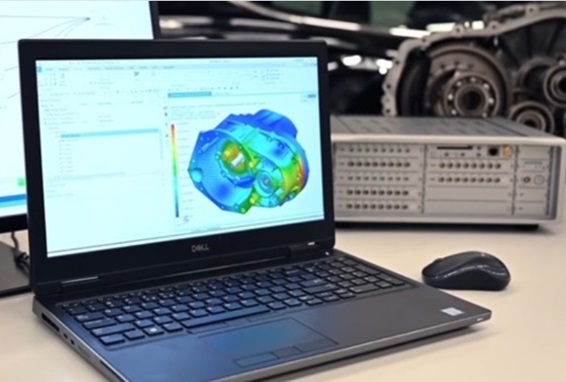

- Simcenter Testing solutions integrate multi-physics data acquisition hardware with a complete suite of data management, analytics, and modeling software, covering a wide range of test needs.

- Simcenter automotive solutions integrate simulation and test strategies, MBSE, AI and multiphysics expertise with automotive engineering software and balance automotive performance engineering characteristics, optimizing range, efficiency and comfort.

- Simcenter physical testing resources: Your essential overview with links, descriptions, and guidance on the various Simcenter solutions for experimental testing, data acquisition, and more.