Airbus Helicopters: simulation and virtual aircraft

Join Nicolas Damiani as he discusses the role of simulation and virtual aircraft when engineering novel helicopters.

Nicolas Damiani, an expert in simulation and operational analysis in the simulation department at Airbus Helicopters Research and Development in Marignane, France, has spent more than 28 years working in the digital world. Today, he supports the research and development teams at Airbus Helicopters.

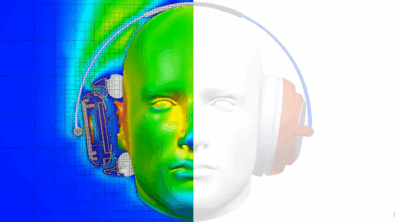

He took some time to explain the ever-changing world of simulation and why Airbus Helicopters is well on its way towards developing a digital twin, a virtual aircraft, or virtual iron bird, as experts in the industry like to call it.

Nicolas, what is your role at Airbus Helicopters today?

As an expert in digitalization and simulation, I have quite a few roles. I have to keep an eye on the standards and the overall simulation architecture. I also support various project teams when needed and prepare the simulation technologies for the future. Basically, I try to make sure that our overall work in simulation results in successful products – delivering our helicopters on time and within budget that also meet quality requirements.

How has the role of simulation changed at Airbus Helicopters?

I have been lucky to witness the evolution of the field over the past 28 years. Starting from simple problem-solving and troubleshooting project work to our groundbreaking model development with Simcenter Amesim, I have seen the simulation side grow brick-by-brick, you might say. Some decades ago, simulation was mainly used in the upper part of the V-cycle for man-machine interfaces and a few research studies.

Today, we have a solid simulation strategy and model architecture in place. Simulation plays an enormously important role in our product development. Our simulation products are now part of the test means for performing the verification and certification activities. It is not yet perfect, but it is well on its way.

Why have simulation and virtual aircraft become so essential?

Simulating a helicopter is an immensely complex task. It has even become more complex. The amount of embedded software and the number of stakeholders, including suppliers, has drastically increased. Nevertheless, the simulation architecture is constantly evolving as certain systems and subsystem models have gained maturity.

The next challenges for Airbus Helicopters will be our capacity to perform joint development in a simulation environment and to progressively replace physical verification by virtual verification, the simulation being a means of compliance.

Like other companies, Airbus Helicopters not only uses simulation to iron out development issues. It also plays a vital role in making sure that we can deliver our products on time and within budget. In our industry, reducing the development cycle and detecting design inconsistencies as early as possible have become key factors of success. Simulation is an answer to our time-to-market and design-to-cost constraints.

In your opinion, how mature is your model?

Our simulation model as a whole could be considered very precise. Of course, there are some areas that are more mature than others in the overall architecture. When we talk about our simulation model, what people tend to forget is that it is actually a hugely complex model that contains 400-to-500 individual models that work together in real-time and in a validated environment.

That must take an enormous amount of computing power.

We are lucky the world of computing is getting faster and faster as well as more efficient economically. When we run the full simulation, we use approximately 24 CPUs.

It doesn’t take up all of our capacity, but it comes close.

What is a typical trend you see today at Airbus Helicopters?

With more precision in our simulation models, we are truly on the right path to predictive engineering in the world of simulation. Look at this mega-model that we have, composed of 400-to-500 individually validated models. It is a system within systems. Just think about all the original source code that goes into something like this. It is immense. The source code is validated. It is locked into the model and we don’t review it. It is precise without having to question it.

Are there specific areas that you are focusing on?

Of course, like other industries, we focus on fuel efficiency. In our development process, this happens at a very early stage during the modeling of the hydraulic, fuel and electric subsystems using Simcenter Amesim. To give an example, the actual model physics, be it the pressure or the pump action, are validated in Simcenter Amesim. With this type of validation so early in the process, you can start to answer bigger questions like fuel efficiency using simulation in a predictive fashion. Our system solution for fuel efficiency that we developed with Simcenter Amesim and Simcenter Engineering is certainly beginning to bear fruit.

Our system solution for fuel efficiency that we developed with Simcenter Amesim and Simcenter Engineering is certainly beginning to bear fruit.

Nicolas Damiani

What are the other ways that you use this model?

Our model is critical to confirm the quality of the prototype, what we call Helicopter Zero. Before the first flight we are beginning to use it for supply chain validation. More and more, we are seeing our suppliers involved and using the validated model to create parts and components that are suited for the job.

What do you think you’ll be focusing on for the next five years?

My job is critical considering the enormous complexity of helicopter development. There are still an enormous amount of bad surprises or things that can go wrong.

Today, you can’t fly without simulation: at the modeling stage, the pilot-in-the-loop stage, the prototyping stage, the validation stage, the flight simulation and the training stage. Simulation is critical to the entire development chain. My main concern in the next years will be to support more engineers as they jump into this new digital way of designing helicopters.

One of the most typical simulation applications that everyone knows is the flight simulator. Is there a connection?

What is surprising after all these years is that the answer is ‘yes.’ In recent years, the simulation world was divided between engineering simulation and training simulation, with limited sharing of models or tools. Basically, a training simulation (like a flight simulator) was developed after the helicopter certification (despite the customer expectation to get trained before receiving their first helicopters) by re-using a limited part of the engineering simulation.

Nowadays, the same simulation product is continuously improved from preliminary design phase up to the certification phase.

At any moment in time, we can derive from our engineering simulation product a training simulation product (compatible with the helicopter delivery).

So you can easily link your development model to the final product or the flight simulator. In other words, you can recycle the virtual aircraft and the digital twin for other applications?

The beauty of simulation is that it can be coupled with various other types of simulation. All you need is the code. This means that you can link the virtual flight simulator as well as pilot-in-the-loop development to practically any application.

This might impact flight tests, other co-simulations like maintenance schedules, and even other in-house development programs.

In fact, the possibilities are endless.

This is rather a tough question: Will there eventually be a truly virtual test bench?

We place an enormous amount of importance on virtual testing at the moment. If you look at how we work with Helicopter Zero and the physical iron bird, this has totally changed! Today, the heart of testing is Helicopter Zero; tomorrow it will be simulation. By using real-time validated models, virtual aircraft, and virtual iron bird (VIB) solutions, we can certainly engineer an extremely accurate helicopter solely in the virtual world.

What does the future of helicopter aviation look like?

Lots of technology, but as experts, it is up to us to make the right choices. There is a lot of technology out there. We need to be vigilant and make the right choices as experts when it comes to smart technology and artificial intelligence.

There is a side of smart technology in which it becomes artificial intelligence and where machines will really be able to learn behavior. This cannot be taken lightly. Once we open that door, there is no going back.

This interview is a reprint from the Simcenter News: the aerospace edition.

Do you want more details about how the virtual aircraft helps Airbus Helicopters innovate its aircraft designs? System simulation has helped the company reduce the fuel system design cycle by a year. Read the case study or watch the video.

Read the white paper to learn how a virtual integrated aircraft (VIA) approach can help you master the aircraft systems integration complexity, from component to full system.