From stardust to simulation: The power of SPH particle refinement

When I was eight years old, I received a telescope as a birthday gift. I vividly remember spending countless hours gazing at the stars and planets, mesmerized by a universe that felt so close yet infinitely distant.

From stargazing to scientific exploration

Even now, even if I’m not a kid anymore, my fascination for the universe remains undiminished.

Recently, my partner and I crafted a simple device from a shoebox (yes, a shoebox!) to safely observe a solar eclipse.

This ongoing interest has continually fueled my curiosity about how the universe works and how planets and stars come together to form galaxies.

Believe it or not, the Smoothed-Particle Hydrodynamics (SPH) technology, which has significant applications today, was actually developed for astrophysical purposes. It was originally used to simulate the dynamics of galaxies and the behavior of stars and planets.

Smoothed Particle Hydrodynamics | Annual Reviews

Monaghan, J. J. 1992. “Smoothed Particle Hydrodynamics.”, Annual Review of Astronomy and Astrophysics 30:543-74. doi: 10.1146/annurev.aa.30.090192.002551.

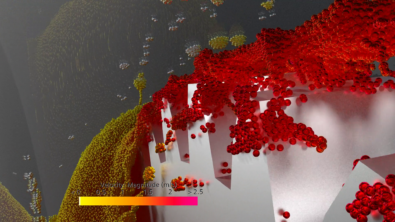

Just like cosmic formation, where countless particles coalesce into refined structures to form stars and planets, the SPH solver in Simcenter STAR-CCM+ 2510 now offers local particle refinement. But you don’t have to go to outer space to make use of this capability: it can actually be used for any down-to-earth application, like, for example, to better capture the oil around planetary gears. And no, planetary gears are not an astrophysical application, even though this thing is pretty close to one:

Enhance simulation precision with SPH particle refinement technique

In previous versions of SPH in Simcenter STAR-CCM+, achieving higher fidelity required refining the particle size, which inevitably increased simulation time. Conversely, opting for faster simulations meant coarsening particle size, sacrificing accuracy. This is the classic CFD dilemma with no easy solution.

Now, with version 2510, Simcenter STAR-CCM+ introduces local particle refinement for the SPH solver, allowing you to enhance flow accuracy precisely where it’s needed without necessitating a fine particle size across the entire fluid domain. This new capability enhances precision in critical areas while maintaining efficient simulation time, offering a balance between local high-fidelity results and computational performance.

The performance improvement largely depends on the application and the size of the refinement area. In the SPH solver’s adaptive time-stepping, the chosen time step is still determined by the finest particle size. Consequently, the performance boost is not driven by the time step but achieved by reducing the total number of particles compared to a fully refined particle simulation. As a result, the more localized and specific the refinement areas are, the greater the performance gains you will experience.

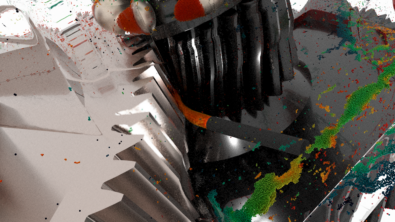

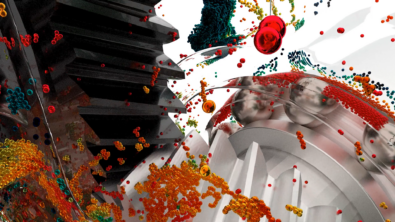

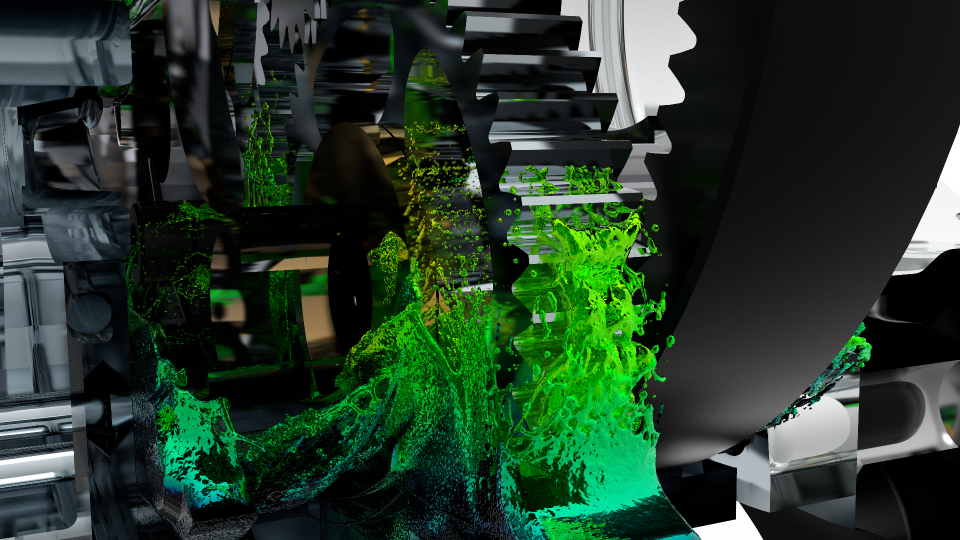

As illustrated in the animation, you now have the ability to locally create geometry particle refinement criteria using block, cylinder or/ and sphere shapes. In the example, cylinder refinement criteria have been defined around each gear to accurately capture the oil distribution close to the teeth.

Your simulation can incorporate one or multiple refinement shapes, and they can even overlap as needed, especially when dealing with complex geometries such as gear teeth. You can define up to 10 levels of refinement, allowing particle size specifications to go below one micrometer, starting from a base particle size of 1 mm.

Also noteworthy is the ability to assign a coordinate system to the refinement shapes. This is particularly useful if you need the refinement to follow a moving solid, ensuring it maintains an accurate resolution while moving along a trajectory in space.

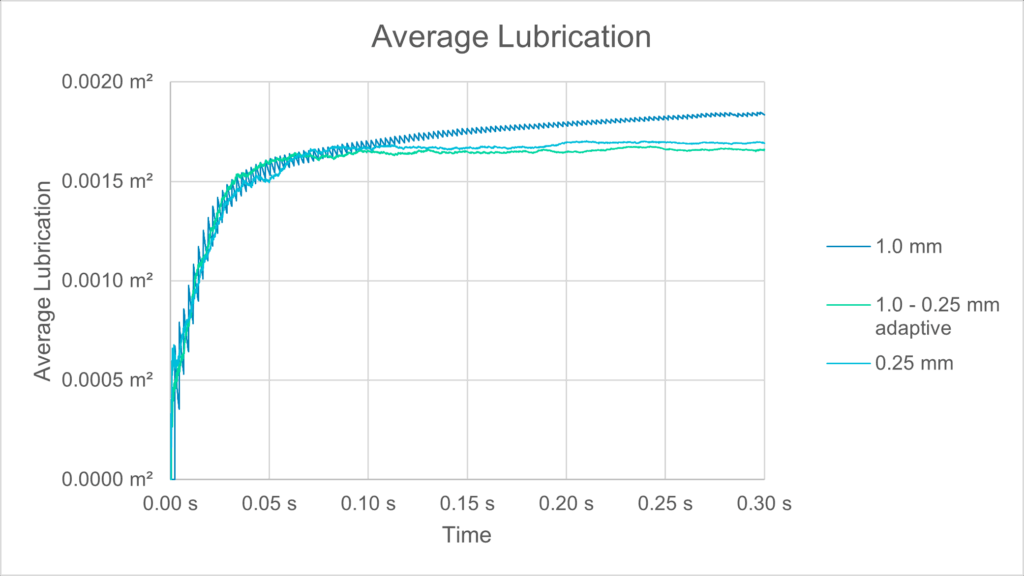

To demonstrate the higher fidelity benefit for this planetary gear application, this chart depicts the average wetted surface over time. As shown, the simulation using particle refinement (particle base size of 1 mm using two levels of refinement) achieves accuracy that closely matches the finest simulation (0.25 mm). In contrast, it outperforms the coarse simulation (1 mm), highlighting the effectiveness of particle refinement in balancing precision and computational efficiency.

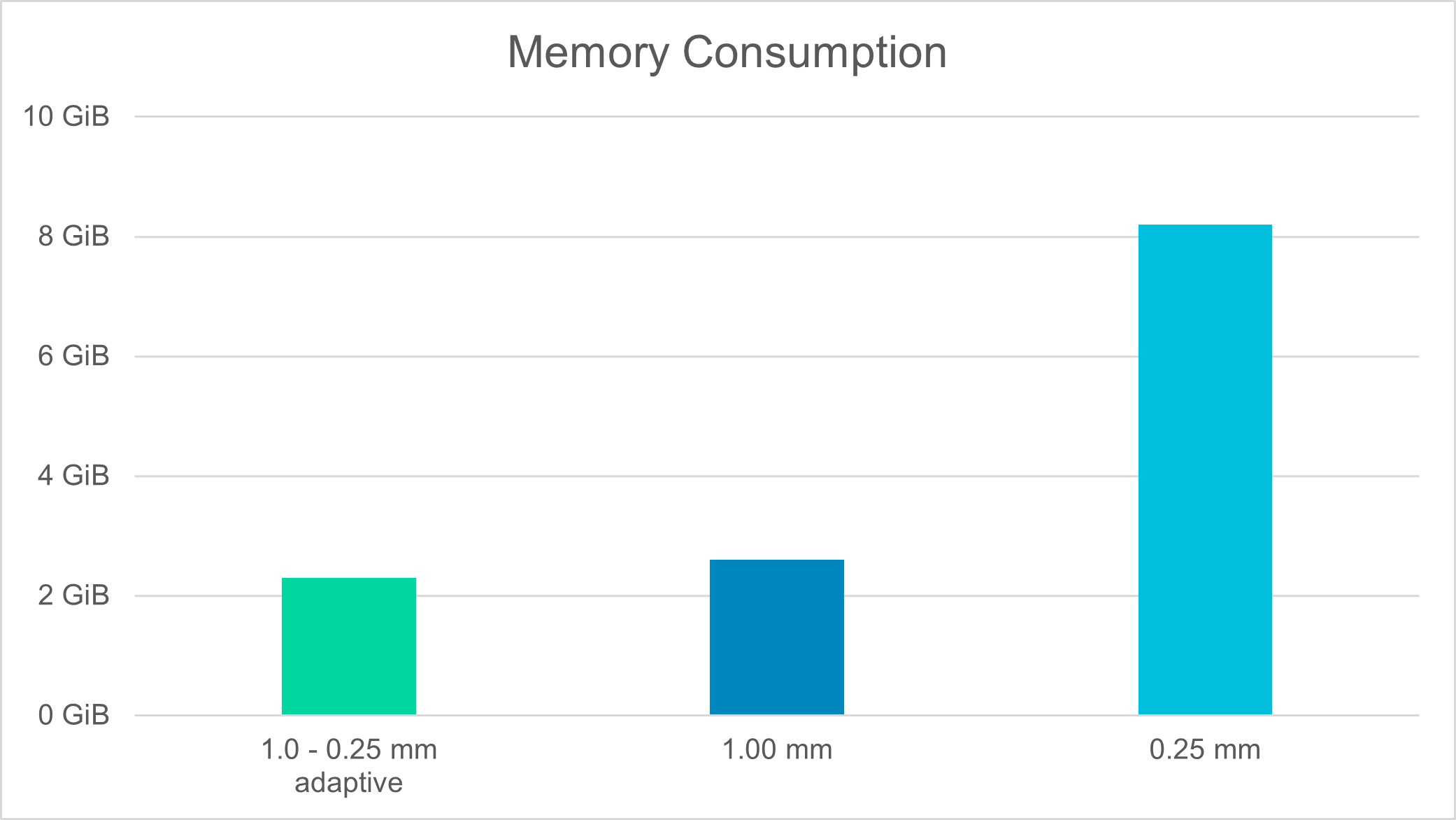

Another key advantage of particle refinement is its significant reduction in memory consumption. As illustrated above, using particle refinement results in a fourfold decrease in memory usage compared to the finest simulation, enabling you to efficiently handle more complex cases.

Simplify planetary gearbox simulation with just a few clicks

Just as effortlessly as planets revolve around the sun in our solar system, setting up a planetary gearbox in Simcenter STAR-CCM+ has never been easier. Starting with version 2506, the new kinematics solver allows for the use of Planetary Gear and Revolute Joint Body Couplings, enabling you to configure motions with just a few clicks.

Additionally, version 2506 introduced enhanced data analysis capabilities. You can now measure mass flow or various other quantities across section planes, thanks to the compatibility of the SPH solver with constrained plane and arbitrary section-derived parts.

Furthermore, visualization of the free surface is now possible using the SPH solver’s compatibility with the iso-surface derived part of the liquid volume fraction.

Those enhancements in the motion and data analysis contribute to a faster setup and getting more insights into the quantitative solution.

Accelerate SPH simulations with lightning-fast GPU workflows

In Simcenter STAR-CCM+ 2510, SPH simulation feels akin to traveling at the speed of light, thanks to seamless GPU acceleration compatibility throughout the entire workflow. The solver supports native GPU acceleration since version 2410 for single GPU and expanded to multiple GPUs in version 2502.

With the latest version 2510, data analysis capabilities are now also ported to GPU hardware. As a result, you can now utilize and visualize point probes, free surfaces, constrained plane sections, and arbitrary sections derived parts up to five times faster compared to before. This allows for rapid solution analysis, maintaining your workflow at a lightning-fast pace.

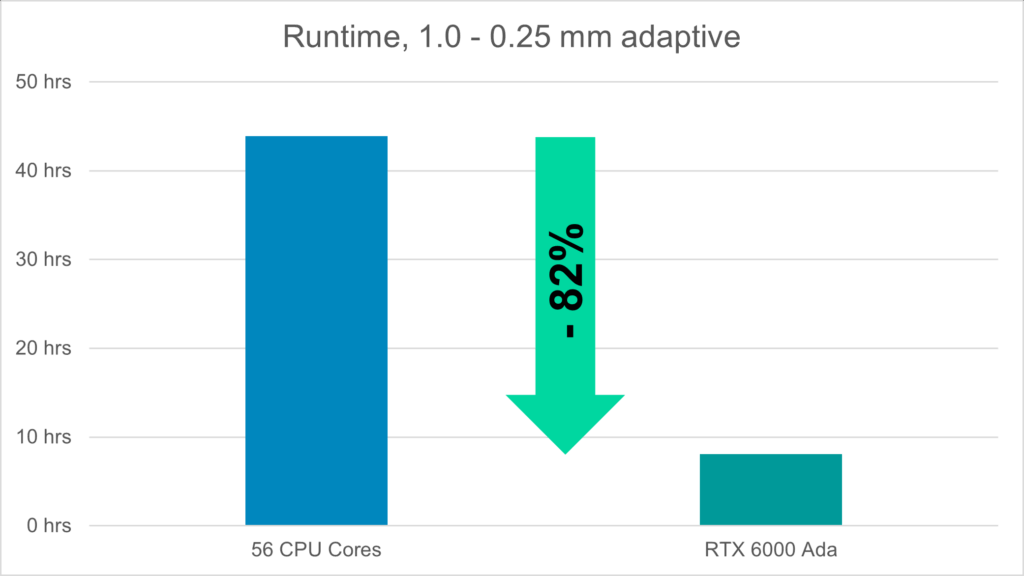

In this specific example, running the planetary gear lubrication simulation on an NVIDIA RTX6000 GPU achieves a speedup of nearly five times faster compared to using 56 CPU cores. This demonstrates that the entire workflow for this application, including particle refinement, is fully optimized and compatible with GPU acceleration.

Explore new simulation frontiers with enhanced SPH capabilities

Simcenter STAR-CCM+ continues to advance its SPH solver with significant enhancements, including local particle refinement, a streamlined workflow for planetary gears, and additional data analysis capabilities, as well as robust GPU acceleration.

With more accuracy, faster setup, and runtime, the SPH solver may help you reconnect with your inner child by looking at all new types of planets and stars in planetary and sun gears. And ultimately, we want to enable you “to boldly go where no (wo)man has gone before.” Perhaps even for your SPH simulation, one day space will become the final frontier.

Stay tuned to explore more exciting new features in Simcenter STAR-CCM+ 2510!