Efficient, flexible and open test data acquisition

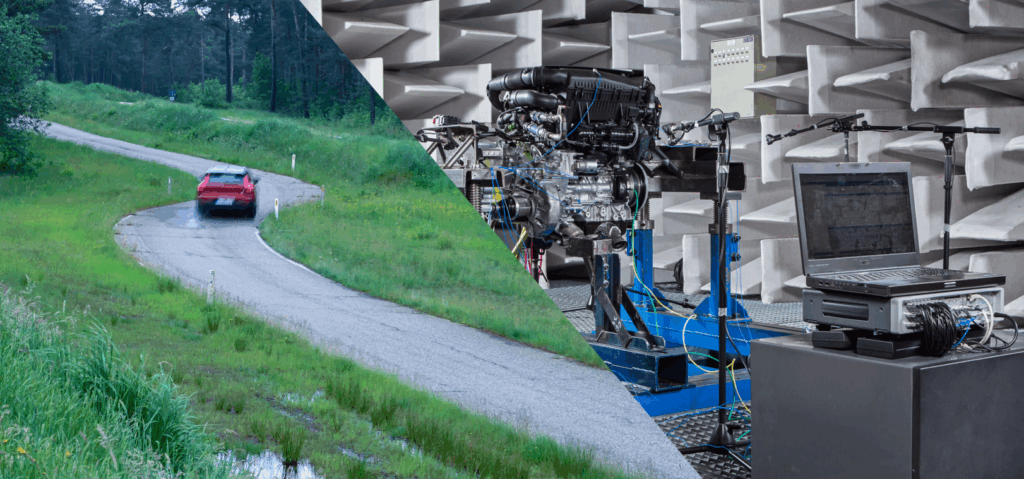

In today’s fast-paced world of research and development, where innovation is driven by the demand for smarter, more connected products, test engineers face a myriad of challenges. Taking the automotive industry as an example, the push for autonomous driving, electrification, and enhanced vehicle connectivity intensifies these challenges, requiring testing teams to manage complex data acquisition from diverse sources, tailored hardware and software configurations, and seamless integration with third-party tools. Inefficient communication and scattered instructions further compound these issues, threatening the agility needed to keep up with industry advancements. Addressing these hurdles is crucial not only to refine testing processes but also to stay competitive in sectors where precision and efficiency are paramount.

Let’s break down some of the challenges just mentioned and explain how we can tackle them with modern data acquisition systems.

Challenge #1: Inefficient communication

While working on research & development projects in the context of vehicle dynamics performance measurement and evaluation, durability proving ground testing or NVH testing, I have always dreamed of a system that would allow me to properly plan things in advance, such that I could automate and easily execute the testing activity, and thus relieving me from the big stress of having to collect and deliver complete and accurate results.

I had always felt like the traditional pen and paper or excel tables-based workflows were always inefficient, error-prone, and difficult to share with people or integrate in a consolidated workflow. This applied to the situations where I would delegate some testing tasks to colleagues or test engineers, or even where I would plan projects or activities that I had to later execute myself. Paper gets lost, meanings get interpreted incorrectly as messages get passed around resulting in inefficient communication, planning, and ultimately unproductive test campaigns.

Challenge #2: Complex data acquisition

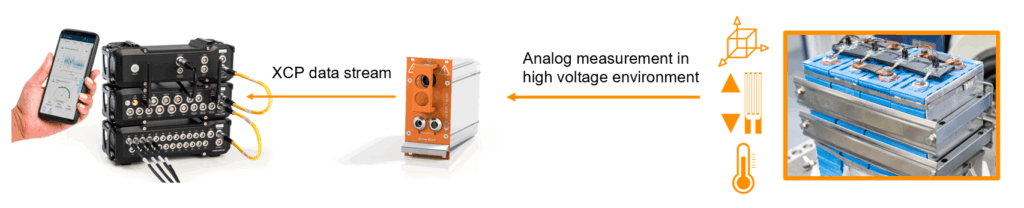

Choosing the right hardware for a given test campaign can also be challenging as we need to collect data from a multitude of different sources and nature, including analog and digital data, connecting to vehicle buses, and having sometimes to combine and integrate different tools from different brands together. For example, you must connect to vehicle digital buses to get vehicle status or dynamic information, or you might need to safely measure in high-voltage environments on the new electric vehicle under development, while still measuring all your analog data.

Challenge #3: Diverse configuration requirements

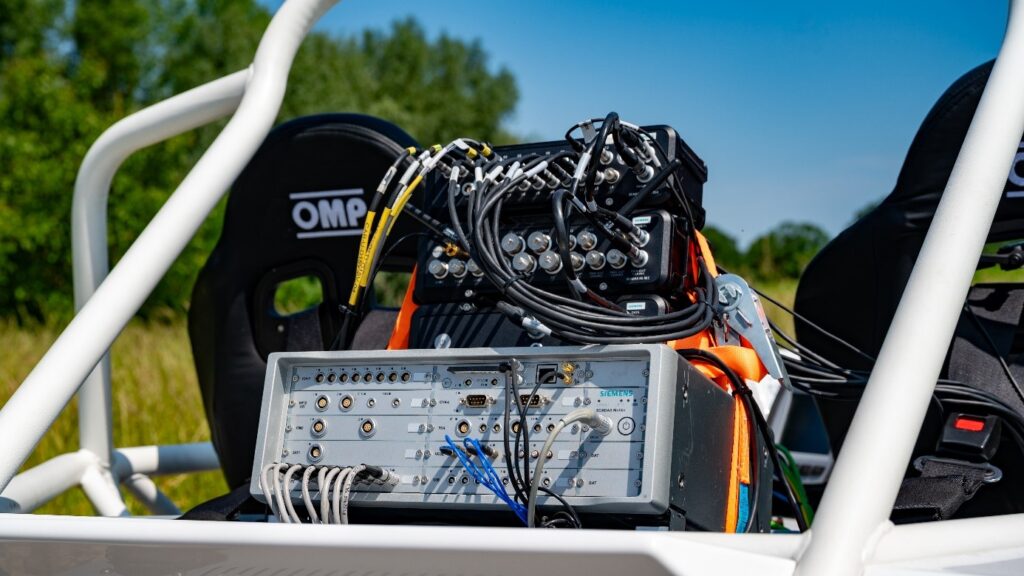

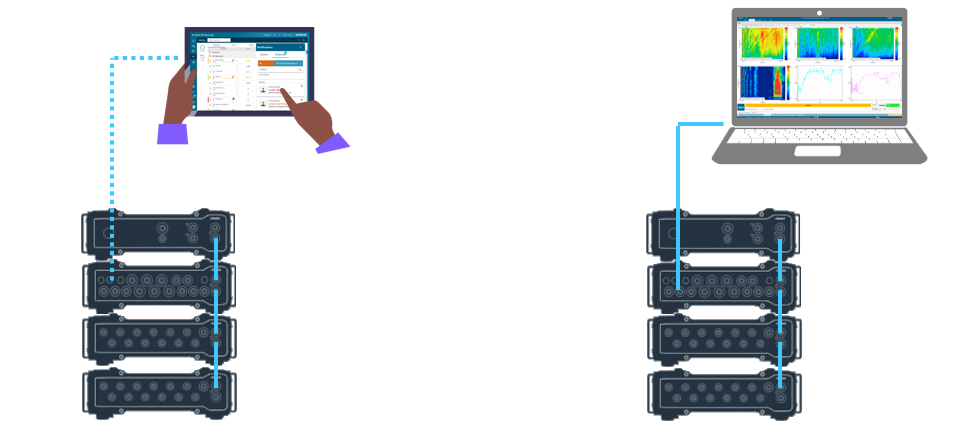

Furthermore, in some cases you have got to measure with a PC in the car or in the lab because you want to access higher processing capabilities. In other projects, you may want to use a more rugged data acquisition system with less wired connections, hence a PC-free or standalone acquisition system with just a phone or tablet connection for instructions to the driver for easy control of the acquisition.

From a cost perspective, you always want to maximally reuse all the hardware you have already invested in, and so the need to combine different pieces of hardware from your closet depending on the different data sources or channel count you need for a particular test.

Challenge #4: Integration with third-party software

Nowadays, testing program integration does not only happen on hardware level, but of course also on software level since your legacy processing tools might be also from different vendors. Many systems are not able to connect.

Simcenter SCADAS RS can help you overcome these challenges

Simcenter SCADAS solutions for physical testing are addressing these and other challenges with the new 2506 software and hardware releases, bringing more efficient, flexible and open data acquisition.

In the rest of this blog, I will guide you through some of the new capabilities that can make your testing more efficient, flexible and open with the Simcenter Testlab ecosystem of hardware and software products.

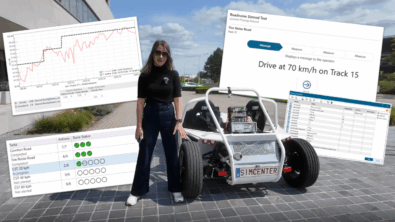

More efficient communication with the Schedule Designer

When it comes to defining and communicating the testing schedule to test engineers and technicians, the new Scheduler App comes in handy. With this application, you can design the test plan in terms of tasks and maneuvers, with a simple drag and drop easy-to-use interface. This step can be done by the test manager or requestor of the test directly within the software. No more pen and paper.

Once the test schedule is defined, it is saved and seamlessly transferred to the Simcenter SCADAS RS Recorder App which then exposes the test schedule to whoever will perform the test. The schedule will guide the driver or test executor through the tasks and maneuver to complete the test campaign exactly as the test author defined it and avoiding the issue of a technician missing of forgetting to complete a task. By the way, if you did not hear or know about the Simcenter SCADAS RS Recorder App, you can learn more about it in this blog: Simcenter SCADAS RS delivers unmatched standalone but connected in-field data collection experience

Dedicated back-end data validation and processing steps can also be defined for each task to execute automatically when each step is complete. This means the test technician knows if the test went ok before ever leaving the track, which reduces expensive re-tests in the future. It also reduces burden on the tester so that they can simply focus on executing the test campaign. Learn more on how to define the testing schedule and operator instructions.

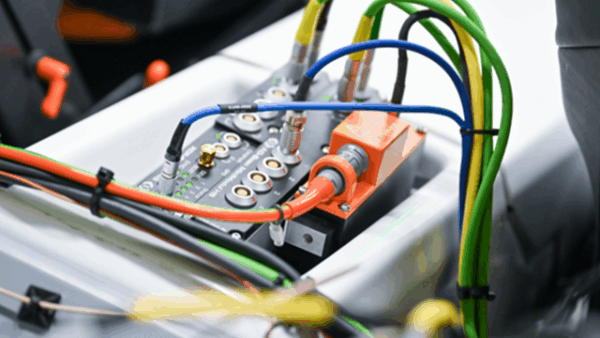

Open to 3rd party systems: XCP over Ethernet with PTP Synchronization

With the electrification and development of hybrid and electric vehicles, there is an increasing need to measure signals and gather sensor data from high voltage environments, such as electric battery compartments to study durability or acoustics and NVH performance of sub-systems. Third-party devices and acquisition modules, such as those from CSM GmbH, exist and are used to measure safely in those environments, and you can easily connect these devices to Simcenter SCADAS RS hardware through an XCP over Ethernet digital interface with high precision Precision Time Protocol (PTP) synchronization. The Simcenter SCADAS RS system can hence be used as a central device to collect data from the multiple sources delivering fully integrated and precisely synchronized data. Learn more about how to perform NVH measurements in High-voltage zones.

This allows measurements to be carried out in electric vehicles battery compartments

Flexible configuration and acquisition options with Simcenter Testlab Neo

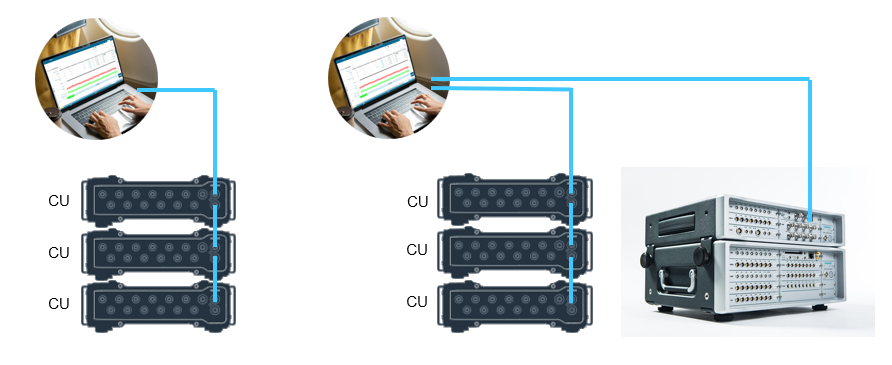

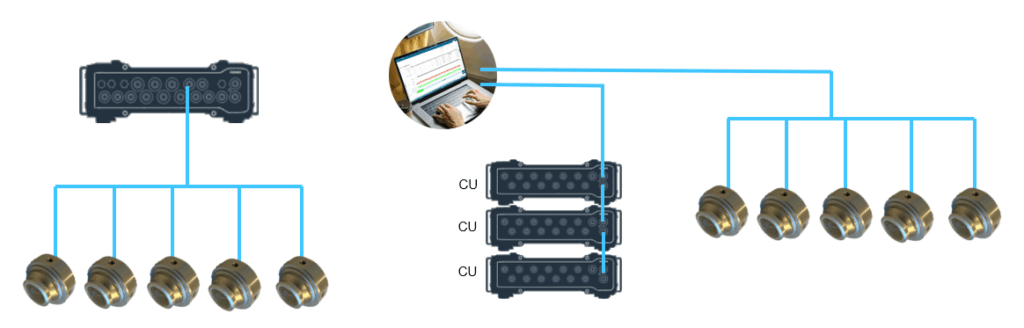

You can configure the Simcenter SCADAS RS in several flexible ways to match diverse testing scenarios and requirements. In standalone mode, the system stores data directly on the SCADAS RS unit, eliminating the need for an external PC. With the embedded Simcenter SCADAS RS Recorder App, you can easily set up, launch, and monitor measurements wirelessly – maximizing the system’s ruggedness and reliability. When you need advanced processing or in-depth visualization during testing, simply switch to frontend mode and connect the Simcenter SCADAS RS to a PC running Simcenter Testlab Neo. This setup lets you acquire and analyze data in real time, combining the flexibility of mobile hardware with the robust capabilities of professional software. Learn more about the connectivity options of the Simcenter SCADAS RS at this link.

(Right) Frontend mode – with wired connection and data transfer to Simcenter Testlab

You can now unlock even greater hardware configuration possibilities in frontend mode with Simcenter Testlab Neo. Connect different modules—such as uninterruptible power supply (UPS) units and Conditioning Units (CUs)—without needing a REC unit, unless you require standalone acquisition, onboard data storage, or expanded connectivity. This flexibility empowers you to tailor your setup precisely to your testing demands, maximizing efficiency and adaptability with every measurement.

You can also extend the life of your existing hardware investments even further by connecting Simcenter SCADAS RS with Simcenter SCADAS Mobile, Simcenter SCADAS Recorder, or Simcenter SCADAS Lab frames in frontend mode using Simcenter Testlab Neo. This flexible approach lets you easily scale up your channel count or tap into specialized conditioning modules on existing frames, ensuring you meet the most demanding testing requirements.

What’s more, you can connect external USB cameras directly to your PC running Testlab Neo in frontend mode, in addition to the existing support for camera connections to the Simcenter SCADAS RS REC unit during standalone acquisition. This gives you seamless video integration wherever you need it in your workflow.

Efficiently export data to universal or third-party formats

Unlock a new, streamlined way to transfer your measured data from the Simcenter SCADAS RS system with the innovative Simcenter SCADAS RS Download and Export tool. Now, you can quickly download multiple runs—or your entire day’s worth of testing data—straight to your PC. At the same time, effortlessly convert your files into third-party formats for seamless integration with your preferred applications. This powerful approach accelerates your workflow, giving you immediate access to results and ensuring a smooth transition to the next phase of your project.

Conclusion

In short, the latest features and enhancements in the Simcenter Testlab and Simcenter SCADAS RS ecosystem empower test managers and engineers to conquer the demands of modern physical testing with unprecedented efficiency, flexibility, and openness. Data acquisition becomes faster and more adaptable, giving you the tools to stay ahead in an evolving landscape.

Contact us to know more about any of the elements of the Simcenter Testlab ecosystem of hardware and software products for data acquisition.