Unlock massive savings: how to build a scalable Battery Energy Storage System (BESS) and achieve a $1M payback

Siemens has published numerous blogs about various aspects of green energy production, from Green hydrogen production simulation within Simcenter Amesim to Boost your Battery Energy Storage Systems with Simcenter System Simulation. However, this blog will shift the focus to the crucial role of energy storage in driving sustainability and profitability for businesses. By integrating BESS with renewable energy sources, businesses can unlock significant cost savings, reduce their carbon footprint, and drive long-term profitability.

Let’s discover together the initial phases of a Battery Energy Storage System (BESS) project, focusing on some techno-economic assessments to be successful (OPEX/CAPEX, energy price evolution, load balancing, payback) going through different steps with Simcenter System Simulation:

- To compute your customer electricity bill

- Considering some weather forecasts

- From renewable energies (solar photovoltaic)

- Optimizing the Battery Electrical Storage System (BESS) and control strategy

- Up to typical results in operations based on realistic scenarios

The use case here is a food processing facility near Lyon in France. Some efforts have been dedicated to the modeling of the solar photovoltaic (PV) system integrated with the BESS and consumers around. With its load and heating system represented during a period of 1 year (January to December). The digital twin considers the operations of the solar PV-BESS with different electricity tariff rates structures and PV or BESS unit costs. Therefore, it addresses the techno-economic value of adopting BESS at dynamic tariff rate structures.

Let’s see how System Simulation is driving the digital transformation for BESS.

Best design for operational excellence

As the BESS economy gains unprecedented momentum, companies are racing to meet the growing demand for clean energy. Yet, scaling production while remaining profitable, sustainable and resilient presents a formidable challenge.

BESS producers and equipment manufacturers must overcome fragmented data systems, high energy costs and supply chain complexities to stay ahead. Companies embracing operational excellence are already transforming these challenges into opportunities. By leveraging digital twins and advanced simulations, they are optimizing processes, reducing costs and improving scalability.

Let’s investigate how BESS industry leaders are creating digital plants, enhancing flexibility and building a competitive edge in a fast-changing market. If your company is ready to lead the BESS transition, this is your roadmap.

System simulation plays a crucial role

System simulation plays a crucial role in the techno-economic assessment of Battery Energy Storage Systems (BESS) in the Energy industry, especially when integrated with renewable energy sources like wind turbines and solar photovoltaic (PV) systems.

Here are some key aspects:

- Balancing Power Generation and Consumption:

- Peak Shaving and Load Shifting: By simulating different load profiles, BESS can be optimized for peak shaving (reducing peak demand) and load shifting (moving energy consumption to off-peak times), which can reduce energy costs and improve grid efficiency

- Grid Stability: Simulations can assess how BESS can be used to balance intermittent renewable energy generation with grid demand, enhancing grid stability and reliability

- Integration with Renewables:

- Energy Management: Advanced energy management strategies can be simulated to coordinate the operation of BESS with renewable generation, ensuring that energy is stored and dispatched in the most efficient way. Including the weather conditions.

- Energy Price Evolution:

- Forecasting and Optimization: System simulations can model future energy price scenarios, helping to optimize the operation of BESS for energy arbitrage (buying low, selling high). This ensures that the BESS is used in the most cost-effective manner

- OPEX/CAPEX:

- Cost Analysis: Simulations can provide detailed cost-benefit analyses, including capital expenditures (CAPEX) and operational expenditures (OPEX). This helps in understanding the financial viability and payback period of BESS projects

- Degradation Modeling: By simulating the degradation of battery cells over time, it is possible to estimate maintenance costs and replacement schedules, which are critical for long-term financial planning

Overall, system simulation provides a comprehensive framework for evaluating the technical and economic feasibility of BESS projects, helping stakeholders make informed decisions about investments and operations.

Digital twin for a food processing facility

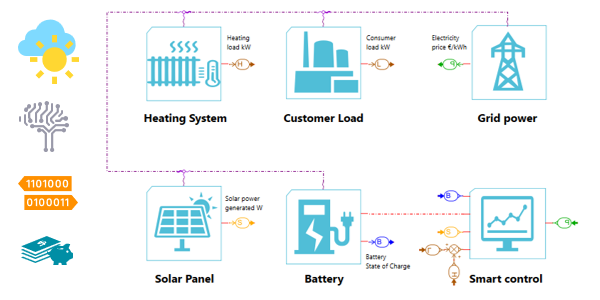

This is a distributed BESS digital twin to predict and optimize the system performances with multi-physics. It includes the Consumers (food processing facility: 20 °C) with the heating system and customer load, the grid connection, the solar photovoltaic with solar panels, the stationary batteries, as well a smart controller based on weather conditions and fluctuant energy price.

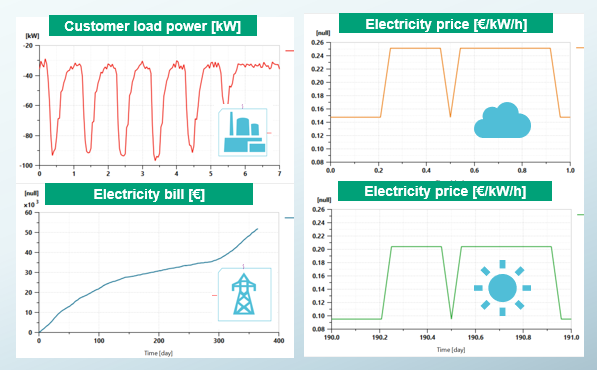

Running the simulation, users can access all the variables from the different subsystems. So the complete information is available, from the consumer load [kW] to the electricity bill over time [€] (1€ » 1$). We consider here an electricity price evolution during the year with its fluctuation within the day. Below are represented two price evolutions in day #1 (January) and day #190 (July) to get the low / high price information at various periods of the year.

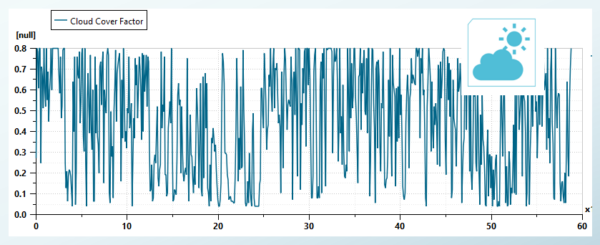

The solar panel includes its GPS localization, turbidity factor (effect of particles, similar to smoke in the air), or cloud cover factor (for weather conditions), …

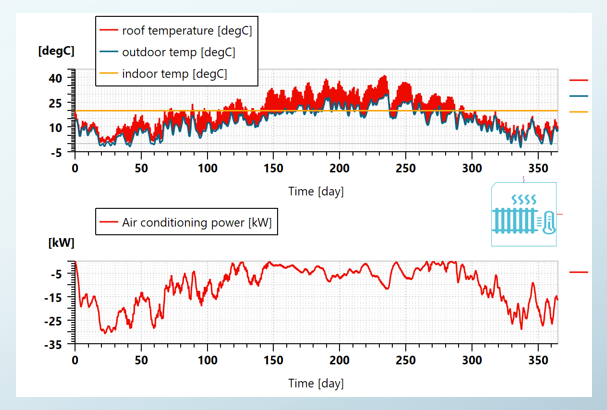

At the same time, the evolution of the outdoor temperature is included from well-known database. So users can evaluate its impact on the heating system considering the setpoint value of the indoor temperature in the factory.

It allows to compute the associated information like for example the air-conditioning power [W], or the power consumptions of all the subsystems around. Doing so, users get a realistic evolution of the powers to evaluate the balancing mechanism and optimal control strategies to put in place for their BESS system.

Macro-analysis of BESS with realistic scenarios

We’re all fine now, the model of the food processing facility is ready for its massive exploitation. The runs are executed in a couple of minutes, opening doors for long and complex scenarios.

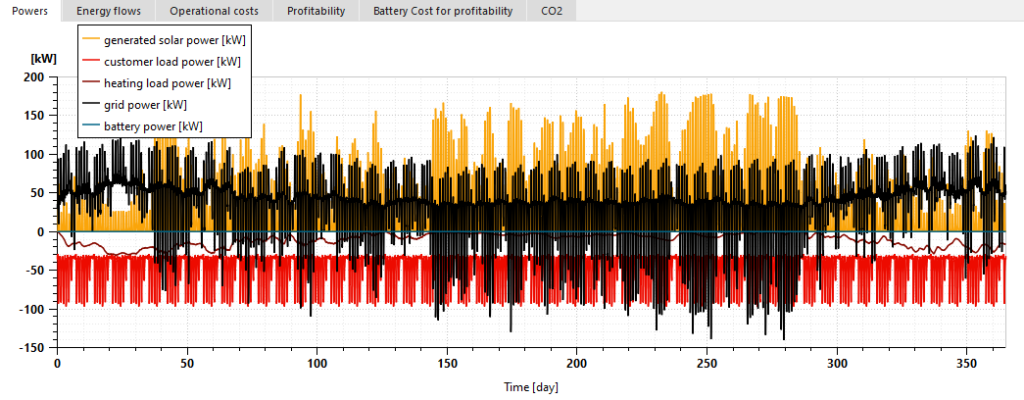

Users can practically evaluate the power generation, storage and consumptions from all subsystems. While the smart control manages the Energy Management System (EMS) to distribute the energy, to store it into the BESS or to deliver it to the grid. All evolutions being either intermittent or dynamic, it’s the reason why a System Simulation tool is required to optimize the sizing and control strategies.

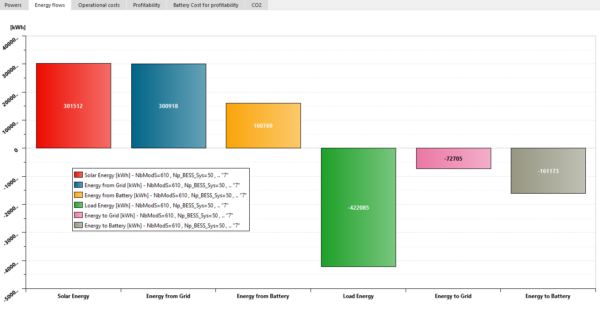

Finally, anyone can access the variations of the energy flows over time. You can for example check the energy generated from the solar panels or brought by the grid, as well as the energy delivered from the battery. It matches the energy needed by the load, while some small energy levels are taken from the grid or restituted to the battery outside the peak periods when the demand is low.

That’s a great achievement! We can already observe nice results thanks to the digital twin with Simcenter System Simulation. But one can go much further, more at the techno-economic side. Let’s see how we can save 1 million $ after 20 years, concurrently reducing a huge amount of CO2 emissions, up to -17 tons of equivalent CO2.

Save 1 million $ and tons of equivalent CO2

We’ll now move to the business and decarbonization aspects to show how you can build a scalable forecast for your BESS systems to measure and replicate significant successes. The digital twin of the food processing facility is equipped with meta information to produce the relevant economic KPIs (key performance indicators) to ensure its monetization, return on investment (ROI) or payback through CAPEX (capital expenses) or OPEX (operational expenses).

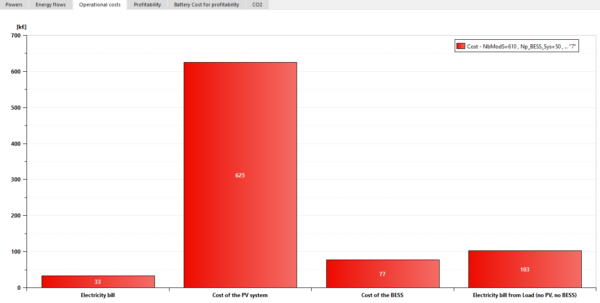

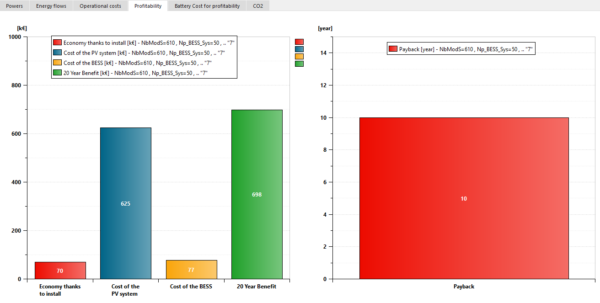

The reference is the electricity bill without solar panels nor BESS. It’s $103k paid during 1 year. Once the solar panels and BESS are introduced, we can capture the new electricity bill, which is now $33k after 1 year with an investment of $625k for the photovoltaic system and $77k for the BESS.

This corresponds to a $70k economy each year for the OPEX thanks to the installation. Then removing the CAPEX costs, we get a $698k benefit after 20 years of operations. While the CAPEX costs are reimbursed after a payback period of 10 years. Knowing the sum of money doubles every 15 years due to the interest rate, we can consider the actual money saving will reach 1 million$ after 20 years.

Please note that it’s a preliminary calculation showing the potential, while things like inflation and maintenance costs are not covered, which is fine for a first estimation.

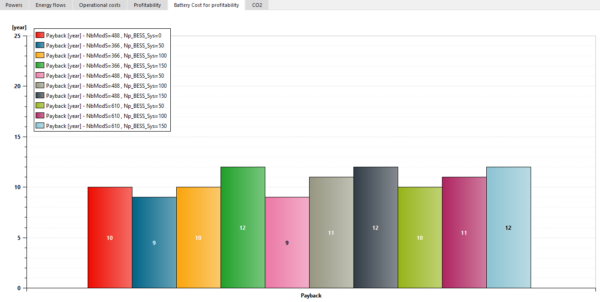

It’s now the right moment to optimize the sizing to extract the maximum value from the new installation. Let’s find out in few clicks the maximal benefits and the best paybacks. We setup a batch study to vary some selected parameters, which we choose to be the number of solar panels (366, 488, 610) and the number of battery racks (0, 100, 150). It’s good to see that we can practically reduce the payback period to 9 years (-11%) in the best configurations, while other choices would bring an extended payback period up to 12 years (+20%).

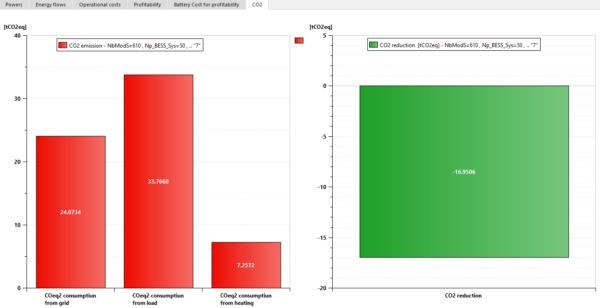

Finally, for the good health of the earth regarding the climate change, it’s also key to look at the reduction of carbon emission thanks to the renewable sources, BESS system, and smart control strategies.

We succeed reaching a tremendous reduction of -17 tons of equivalent CO2 per year. That’s really impressive, isn‘t it? This is our contribution to the sustainability process through decarbonization. All these nice achievements are obtained thanks to the digital twin with Simcenter System Simulation.

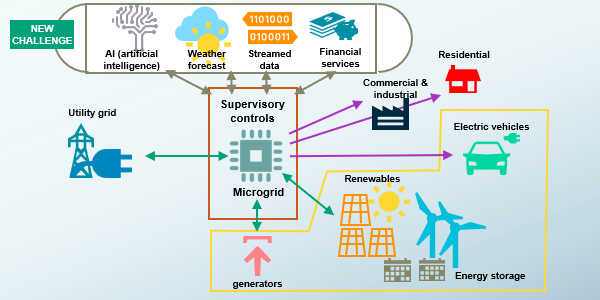

Going further

We could even go some steps further introducing a new paradigm with a grid supervisory control. The most recent breakthrough technologies make possible to combine Artificial intelligence (AI), weather forecast and streamed data. This offline digital twin is converted into an executable digital twin that connects real-time performance data with accurate, well-orchestrated plant information and simulation tools, so you can troubleshoot critical system situations (peaks during switching, …) or benefit even more for the price and CO2 reductions. What a great perspective!

In summary, owner-operators in the global BESS business have a historic opportunity to grow their business and market share in the coming decades. Companies that will emerge as leaders in the delivery business will be those who can conquer the BESS complexity and turn it into a competitive advantage.

System Simulation definitely helps being successful in your BESS journey thanks to digitalization, with system integration and smart controls.

Learn more about Siemens Simcenter Amesim

Simcenter Amesim is the leading integrated, scalable system simulation platform, allowing system simulation engineers to virtually assess and optimize the performance of mechatronic systems.