Inside the battery: discover the power of electrochemical modeling in Simcenter Amesim

Introduction

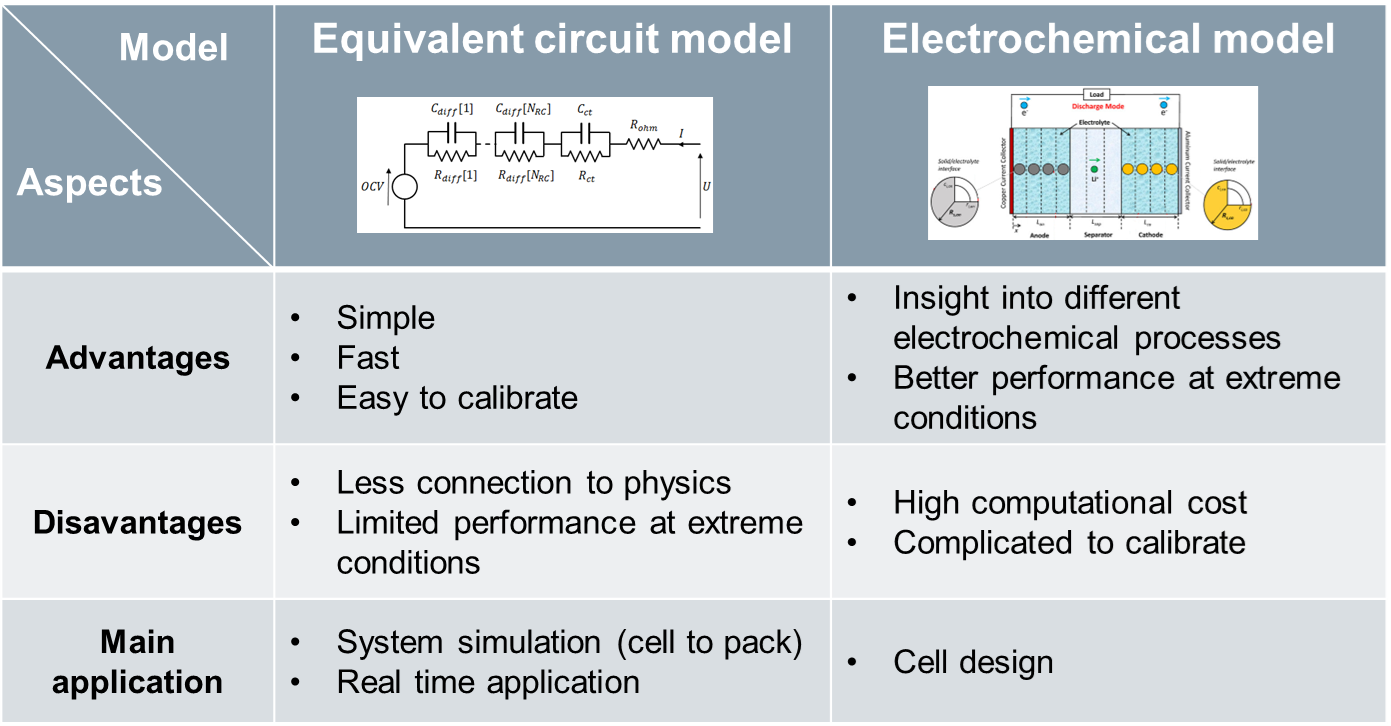

In the rapidly evolving realm of e-mobility and electrical stationary storage systems, it becomes crucial to have precise battery models for effective system design. Battery models can be broadly categorized into two types: the equivalent circuit model and the electrochemical model:

- The equivalent circuit model simplifies the complex electrochemical processes occurring within a battery by representing it as an electrical circuit composed of resistors, capacitors, and voltage sources. This model provides a practical and straightforward approach to simulate battery behavior and is widely used in system-level simulations (e.g., battery pack simulating) and real time application (e.g., battery management system in the vehicle).

- On the other hand, the electrochemical model or P2D (Pseudo-Two-Dimensional) model delves deeper into the intricate electrochemical processes that take place within a battery. It considers the various physical and chemical phenomena, such as lithium-ion diffusion, migration, and chemical reactions, to provide a more accurate representation of battery performance. The electrochemical model considers factors like electrode kinetics, concentration gradients, and temperature effects, making it suitable for detailed analysis and research-oriented studies.

A brief comparison of both models is given in the table below. While the equivalent circuit model offers simplicity and ease of implementation, it may not capture all the nuances of battery behavior, such as lithium plating. Conversely, the electrochemical model provides a more comprehensive understanding but requires more computational resources and detailed input parameters.

In this article, a focus is given to the electrochemical model in Simcenter Amesim. You will find out the main features of this model which allow you to get insight into different critical battery behaviors, such as:

- Electrochemical process inside the battery cell

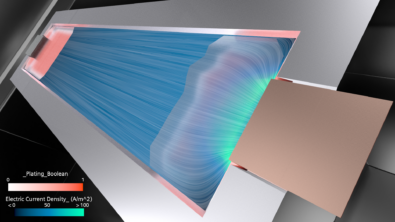

- Lithium plating

- Aging

Simulating the electrochemical process inside the battery

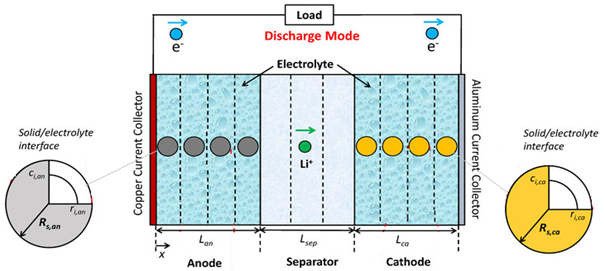

Figure 1 gives a schematic representation of the battery P2D electrochemical model. The active materials are depicted as spherical particles for each electrode. Each electrode is discretized into multiple layers, with each layer containing one particle in contact with the electrolyte. Each particle is also discretized into multiple layers. This approach allows for a detailed understanding of the behavior and interactions of different elements (e.g., active materials, Li-ion, electrolyte) within the battery system. By representing the battery in this manner, the model can capture the intricacies of particle-level phenomena, contributing to a comprehensive analysis of battery internal behaviors, such as the Li-ion concentration at the surface of different particle surfaces, the voltage drops on different elements of the battery, the average anode potential, etc. Simcenter Amesim also offers a simplified version of the P2D model, known as the single particle model with electrolyte (SPMe), which reduces computational complexity by representing each electrode with a single particle. This version is well-suited for scenarios requiring quicker analysis while maintaining effective simulation accuracy.

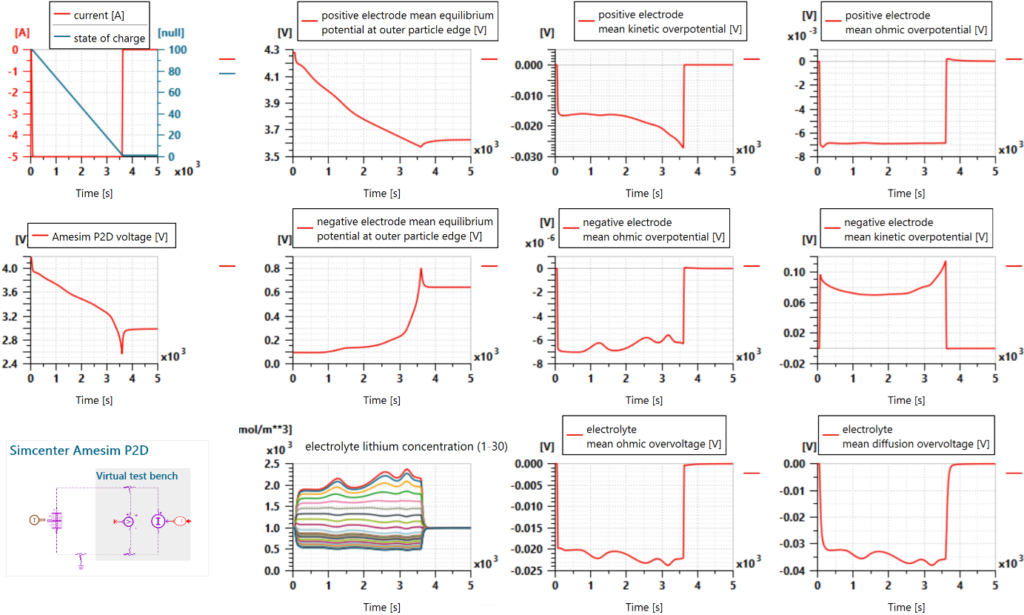

Figure 2 shows the simulation results of a constant discharge with the P2D model in Simcenter Amesim for a 5Ah NMC/SiC battery cell. The parameter values of the P2D model are taken from the work of Chen et al. [2]. Besides the cell voltage, the model can simulate various internal indicators, including the ohmic and kinetic overpotential within each electrode, electrolyte lithium concentrations, and mean diffusion overvoltage in the electrolyte.

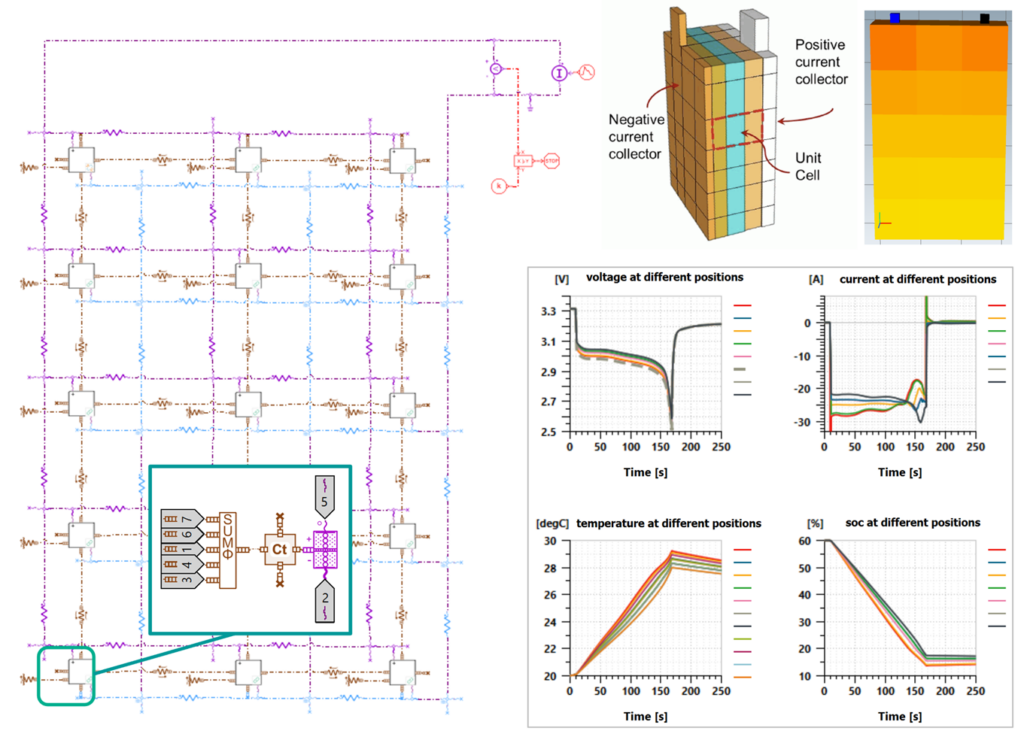

It is also possible to interconnect multiple Simcenter Amesim P2D models to have a first level discretization of the cell. Figure 3 shows such an example with a 4×3 discretization for a prismatic cell. Each discretization node has a P2D model coupled with a thermal mass to calculate the local temperature. The current collectors are also discretized by using resistances. Compared to a detailed CFD simulation with thousands of meshes of the cell, this approach helps to get fast simulation results and limit the scope of the detail simulations to be carried out in a CFD software such as the 3D cell design capabilities of Simcenter STAR-CCM+.

Lithium-plating

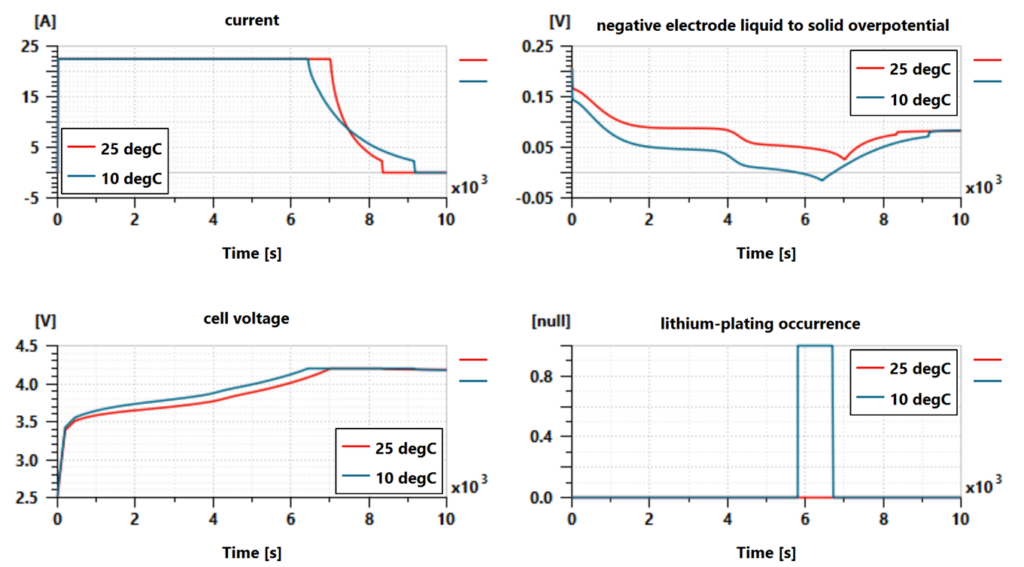

Lithium plating occurs when metallic lithium deposits on a battery’s negative electrode during improper charging (e.g., fast charging at low temperature), leading to reduced efficiency and safety hazards. As fast charging is one of the important usage scenarios for electric vehicles and other battery-based systems (e.g., eVTOL, battery stationary storage systems), employing techniques such as model estimation is crucial for understanding and preventing lithium plating. With the Simcenter Amesim electrochemical model, you can easily get access to an internal variable of the model to detect the risk of lithium plating occurrence. This variable is the negative electrode liquid to solid overpotential. During the charge, lithium plating can happen if the negative electrode liquid to solid overpotential drops below 0 V. Figure 4 shows an example of the CCCV charge simulations results for a 45 Ah NMC/C battery cell at two different temperatures. The results indicate that towards the end of the charge at 10 °C, there is a risk of lithium plating occurrence as the negative electrode liquid to solid overpotential drops below 0 V.

Aging

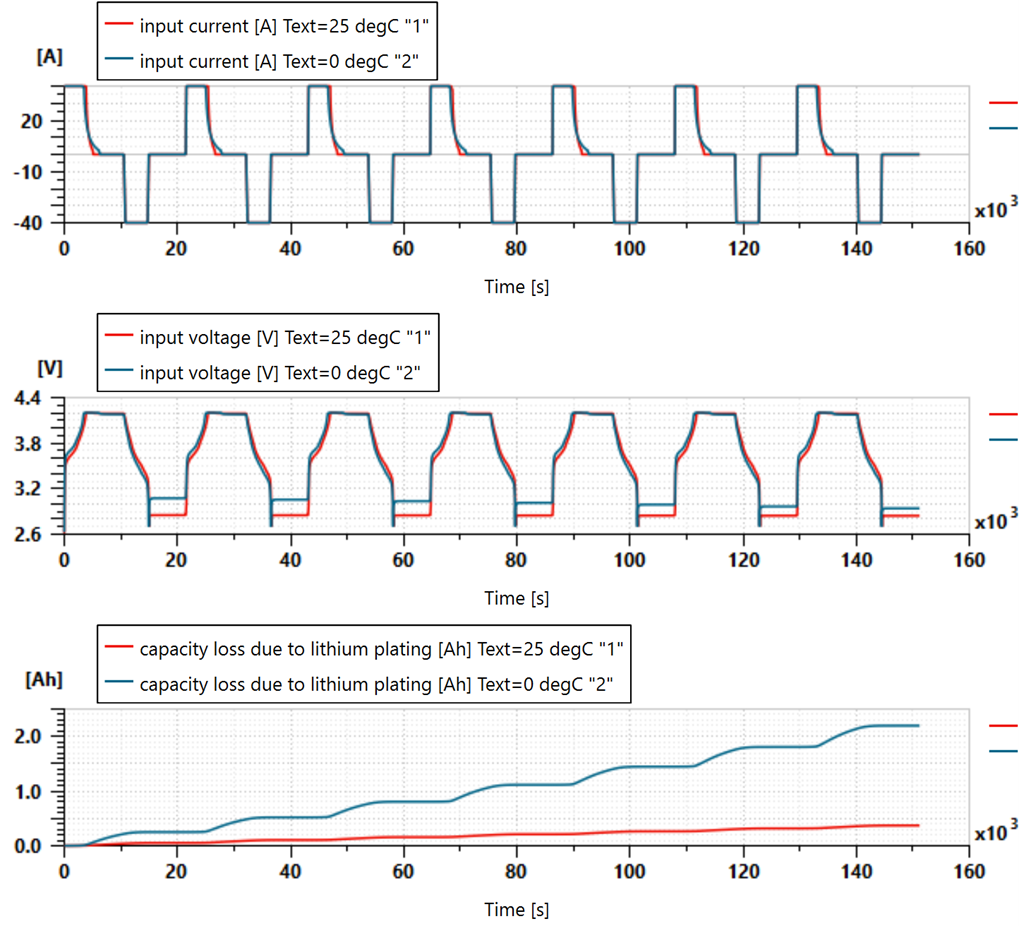

With the Simcenter Amesim battery electrochemical model, the battery aging behavior can also be simulated via the modeling of different aging mechanisms causing capacity loss such as the growth of the SEI layer and the lithium plating. Figure 5 presents an example to simulate the loss of capacity due to lithium plating for a high energy NMC/C cell at two different temperatures.

Conclusion

The electrochemical model or P2D (Pseudo-Two-Dimensional) model is part Simcenter Amesim release 2410. To learn about other new features in this release check out the release blog or read further in this blog to learn how your system simulations in Simcenter Amesim can be drastically accelerated.

References

1. Astaneh, M.; Andric, J.; Löfdahl, L.; Maggiolo, D.; Stopp, P.; Moghaddam, M.; Chapuis, M.; Ström, H. Calibration Optimization Methodology for Lithium-Ion Battery Pack Model for Electric Vehicles in Mining Applications. Energies 2020, 13, 3532.

2. C.-H. Chen, F. B. Planella, K. O’Regan, D. Gastol, W. D. Widanage, and E. Kendrick, “Development of Experimental Techniques for Parameterization of Multi-scale Lithium-ion Battery Models,” J. Electrochem. Soc., vol. 167, no. 8, p. 080534, Jan. 2020

3. Demo “Electrochemical NMC-SiC Pseudo-Two-Dimensional (P2D) battery model comparison”, Simcenter Amesim Help, V2410, 2024

4. Demo “Charging strategies based on negative electrode overpotential – Lithium plating detection”, Simcenter Amesim Help, V2410, 2024

5. Demo “Lithium plating modeling”, Simcenter Amesim Help, V2410, 2024