Is digital transformation in the space industry slowing us down?

Digital transformation in the space industry refers to the process of integrating digital technologies into various aspects of space companies’ mission-critical operations and strategies. It involves leveraging digital tools, technologies, and data to improve efficiency, productivity, and competitiveness.

Now, let’s go back in time. In the 1960s, the US put a man on the moon in just seven years, using a combination of mechanical calculators and first-generation (low-power) computers. Fast-forward to today’s digital age, and the space industry seems to have lost its speed. With the aid of advanced computing power and fast networks, Boeing took over 14 years to develop Starliner, and the Ariane 6 launcher took 10 years. So, is digital transformation slowing us down?

A closer look reveals a huge difference in resourcing: 400,000 people worked on the Apollo program. Contrast that figure with approximately 13,000 employed at SpaceX, which is developing rocket engines, launchers, and human-rated spacecraft at a phenomenal rate.

Digital transformation in the space industry has had a significant impact, streamlining processes, taking away the mundane tasks from engineers and reducing paperwork. This has allowed companies like SpaceX to develop complex systems at an impressive rate with a much smaller workforce compared to previous space programs like the Apollo program. The use of digital technologies, such as AI and machine learning, further enhances efficiency by automating mundane tasks and enabling engineers to focus on more creative aspects.

Attention has now shifted towards the development and production of multiple satellites and the launch of huge constellations and meshed networks. This is a busy area, and the ambition of various new players means that they are beginning to lead the way.

This has created new opportunities for emerging players but also poses challenges for established companies, who need to adopt a new approach to maintain performance and compliance while reducing costs and accelerating processes.

Digital transformation in the space industry to gain a competitive advantage

Digital transformation in the space industry has significant benefits. It allows for the orchestration of spacecraft programs throughout their lifecycle, from mission analysis to disposal. Real-time data availability enables the traceability of design intent and decision-making from concept to qualification.

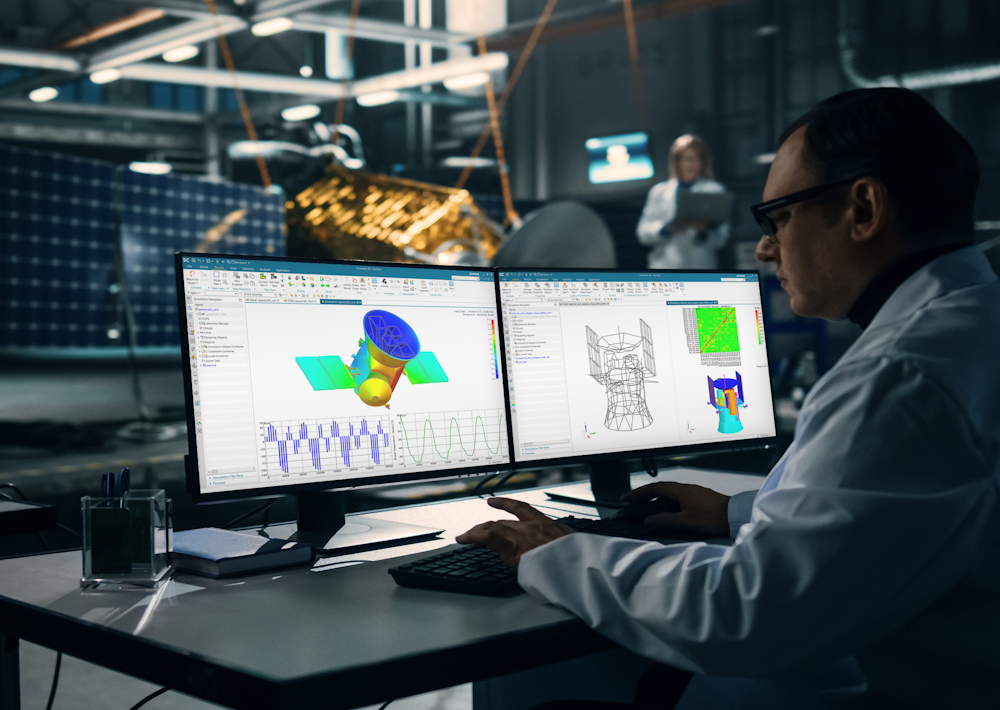

Continuous monitoring of technical performance indicators helps eliminate integration issues, and communication between space agencies and industrial partners is enhanced. The use of integrated physics-based simulation enables better decision-making early in the development cycle. Simulation can predict the behavior of various spacecraft systems, such as solar panels, power actuators, controls, and thermal balance. This leads to more accurate performance predictions and a more robust design.

Several organizations in the space industry have seen positive outcomes from adopting digital platforms and simulation tools. Some have digitized their operations, leading to faster development of their space platforms. Others have enhanced satellite testing with new tools and processes. Additionally, some organizations have reduced the time required for modal survey tests to below four days while being able to accurately identify nonlinearities and analyze 80% of final test data immediately. Major contractors have also adopted a model-based approach involving the use of a common model in a single environment in which boundary conditions propagate across disciplines so that design changes are consistent throughout.

These organizations understand the significance of digital platforms and simulation tools in enhancing efficiency, accuracy, and sustainability in the space industry. To delve deeper into this fascinating topic, you can refer to my latest article titled “Launch it Before You Build it”, which is available in the SAE Tech Briefs Special Report: Space Technology – September 2024.

Unleash innovation and digital transformation in the space industry

You can find a captivating video on YouTube that showcases Simcenter and its multi-attribute solutions. In less than 4 minutes, the video demonstrates how Simcenter empowers space engineers to innovate by digitally analyzing and physically validating spacecraft. This ensures a harmonious balance across all critical performance aspects.

A recently developed page on Simcenter aerospace engineering software serves as a comprehensive resource for learning more about digital transformation in the space industry and what real engineers are saying about Simcenter. If you want to drive digital transformation in the space industry and implement an integrated simulation and testing strategy, this page will provide valuable information on how to increase productivity, achieve faster design iterations, and ensure successful program outcomes.

Comments

Comments are closed.

This leads to more accurate performance predictions and a more robust design.