Accelerate and automate your in-field data collection process with Simcenter SCADAS RS & Simcenter Testlab Workflow Automation

Imagine you could fully automate in-field measurement campaigns, from data collection all the way to data processing. Wouldn’t that be nice?

In this blog, I want to share with you a recent demonstration I did on this specific topic to an audience of 100 automotive engineers. I got them speechless for a few seconds. My goal with this blog is to get you inspired and hopefully speechless too.

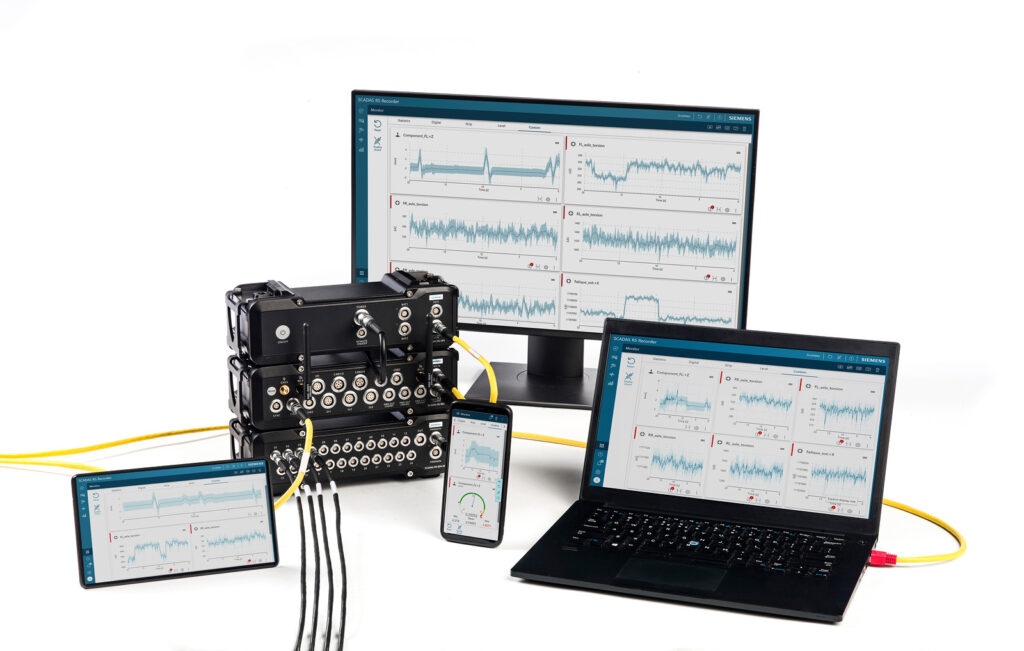

For this demonstration, I used the Simcenter SCADAS RS. “SCADAS what?”, you say? It’s the newest member of our Simcenter SCADAS hardware product family, empowering our customers to effortlessly acquire and synchronize an array of sensors for various applications, including durability and NVH testing.

Before diving into my demonstration, let me briefly explain some of the key connectivity features that exist on Simcenter SCADAS RS.

Remote connectivity and Remote CONNECTIVITY are not the same

In my previous blog, I discussed the flexible system access offered by Simcenter SCADAS RS. This eliminates the need for a dedicated laptop or PC, as well as the hassle of connecting LAN cables and installing specific acquisition software or licenses. To access the acquisition system anytime and anywhere, all you need is a device with a screen and an internet browser. This versatile access is made possible thanks to the on-board Wi-Fi and license-free app pre-installed on the Simcenter SCADAS RS hardware.

Wi-Fi provides some freedom, but there are situations where having an engineer present in or near the vehicle is not possible or preferred. Additionally, when an engineer needs to be physically in the vehicle, they can only monitor that specific vehicle and no others. Moreover, test engineers are valuable but expensive resources that should be used efficiently. Having an engineer waiting in the car until a test is finished is not the most efficient use of their time, right?

However, by connecting a 4G or 5G router to the Simcenter SCADAS RS, you can create a measurement system that is accessible from anywhere in the world! We offer a 5G router called the SCALANCE router, with excellent water and dust protection, making it a perfect match for the rugged Simcenter SCADAS RS.

Once you connect this router to the Simcenter SCADAS RS, you can access the measurement system (and embedded web app) just like when you’re connected via Wi-Fi. Simply grab your PC, tablet or smartphone, enter the IP address in the internet browser, and you’re good to go! The big difference now is that there are no limitations on the distance between the measurement hardware and the test engineer. The vehicle and Simcenter SCADAS RS can be in the south of Africa or the north of Europe, while the test engineer remains in their office, remotely monitoring the progress of the test campaign.

Got multiple vehicles on the road? No problem! Simply open another tab in your web browser with the IP address of the respective SCALANCE router and Simcenter SCADAS RS. Like this, the test engineer can effortlessly monitor an entire fleet of test vehicles from the comfort of his office chair. Plus, while waiting for one vehicle’s tests to finish, the engineer can start validating data from another vehicle or previous runs. Pretty cool and time-saving, right?

Automation of a full measurement campaign put to practice

Most data acquisition systems on the market are not only limited in the way to connect, but also make the data validation process extremely time-consuming.

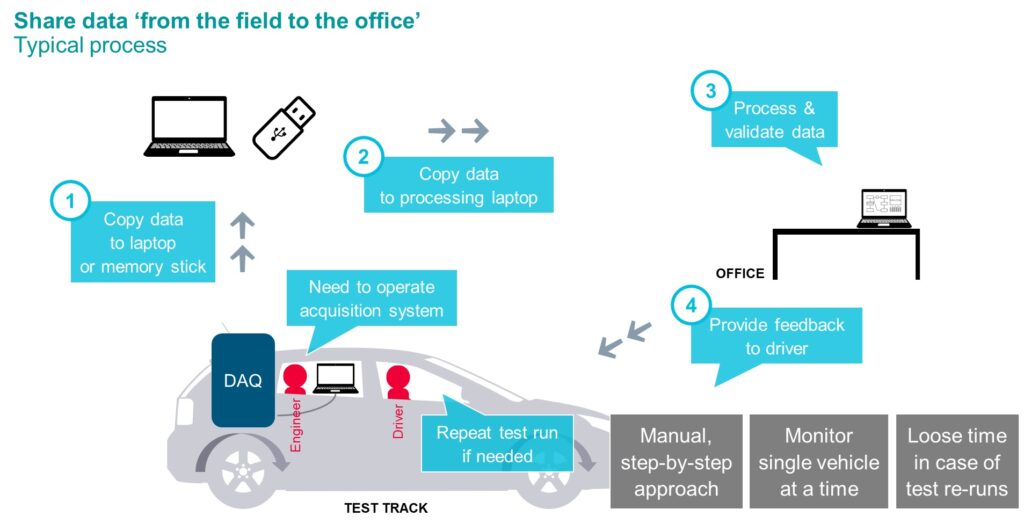

The test engineer always has to go through a series of manual steps, from copying data to their laptop or memory stick in the field, transferring it to the processing PC in the office, manually processing and validating the data, and then informing the driver of the results. If the results are not satisfactory, he has to repeat the test runs, wasting even more time and money.

But fear not! We have a solution for you: Simcenter Testlab Workflow Automation!

As promised, let me take you through a demo I recently conducted during a large seminar event at a university for 100’s of automotive engineers.

Vehicle instrumentation

I had an electric vehicle fully instrumented with various demo sensors, all connected to the U12 universal signal conditioning unit of the Simcenter SCADAS RS system. To demonstrate the flexibility in sensors to be connected to one unit, we selected a range of very different sensors: a uni-axial DC accelerometer, an LVDT displacement sensor, a string potentiometer (also a displacement sensor), a quarter bridge strain gauge, a microphone and a tri-axial accelerometer. The universal unit eliminates the need for multiple dedicated units in the vehicle. More details on this in one of my past blogs.

Remote connectivity

To access the Simcenter SCADAS RS system remotely (since the vehicle will be out of Wi-Fi range), a SCALANCE 5G router was attached to the REC unit.

This setup not only allowed real-time feedback on the measurements through the embedded web app, but also provided GPS location data enabling us to view the vehicle’s location.

Demo objectives

The demo had following main objectives:

- Automatically transfer measured data from the vehicle to my PC,

- Check in an easy way if the driver followed pre-agreed speeds on the university premises,

- Conduct in-depth automatic processing for durability and NVH analysis

- And last but not least, show how to save time, money & effort in the whole measurement process by streamlining and automating data transfer & analysis.

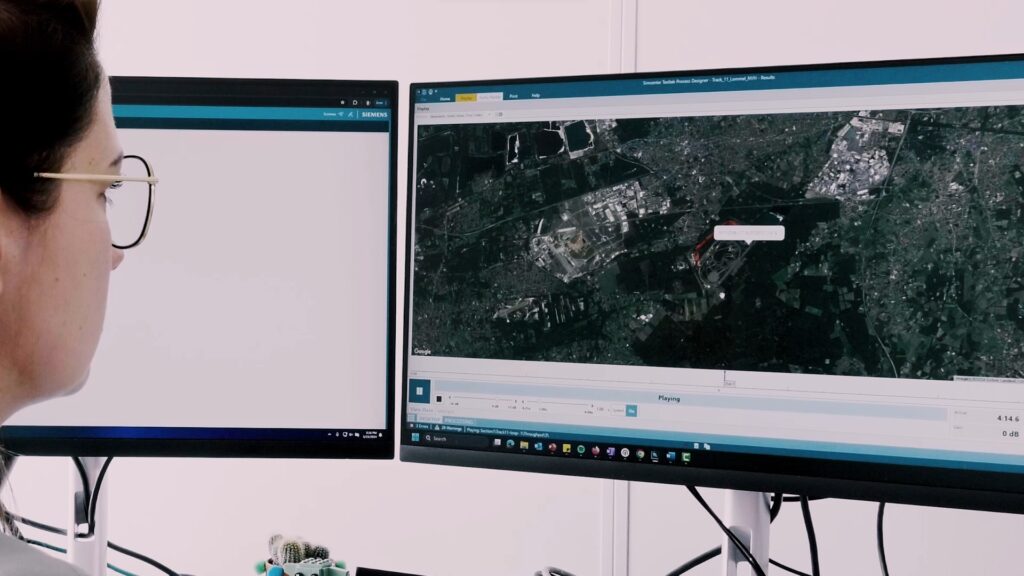

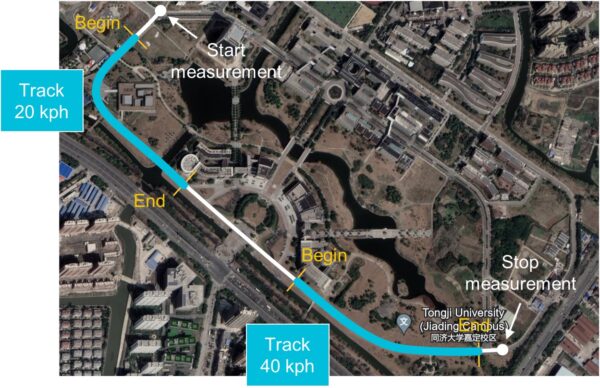

The driver had to navigate the university’s internal road network, more specifically the part marked in white above. Our focus on this particular road were two sections representing different speed tracks. The first section required the driver to maintain a speed of 20 kph, while the second section allowed for a speed of 40 kph, as marked in blue.

Building in intelligence

Normally, a driver has to manually start and stop the measurement at the beginning and end of each section. However, with a Simcenter Testlab Neo process I can build-in a lot more intelligence into the system, allowing drastic simplification for the driver.

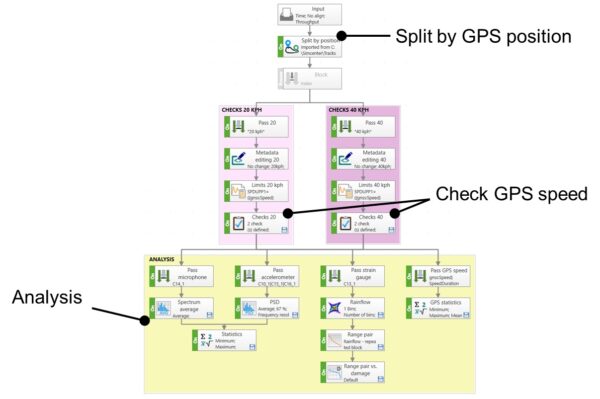

The total measurement, marked in white, is automatically divided into the two specific segments (blue sections). This is done with a method in my process that can automatically detect and cut segments, based on GPS location. As a result, the driver only needs to start the measurement when they begin driving and stop it at the end of the “test track”.

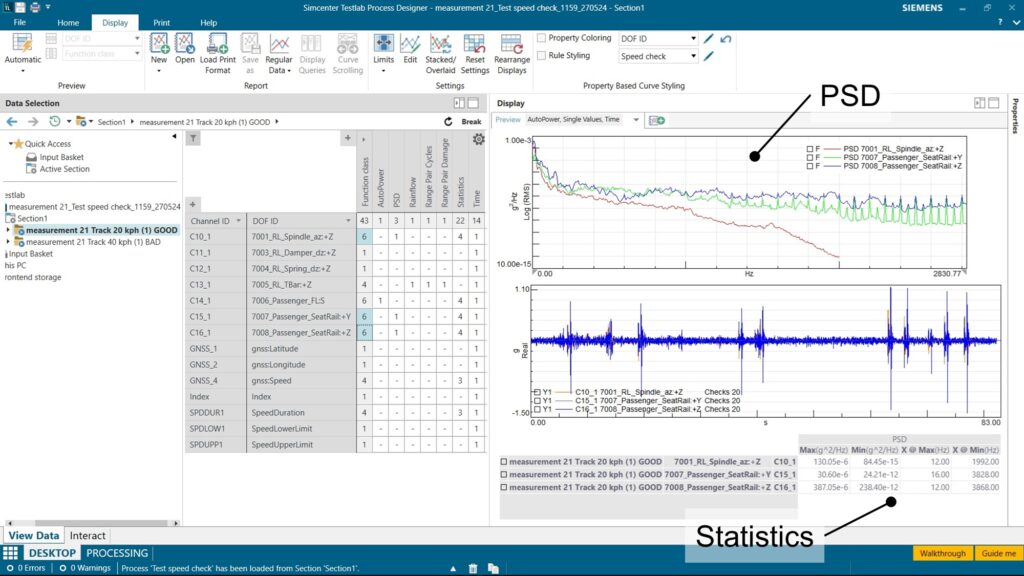

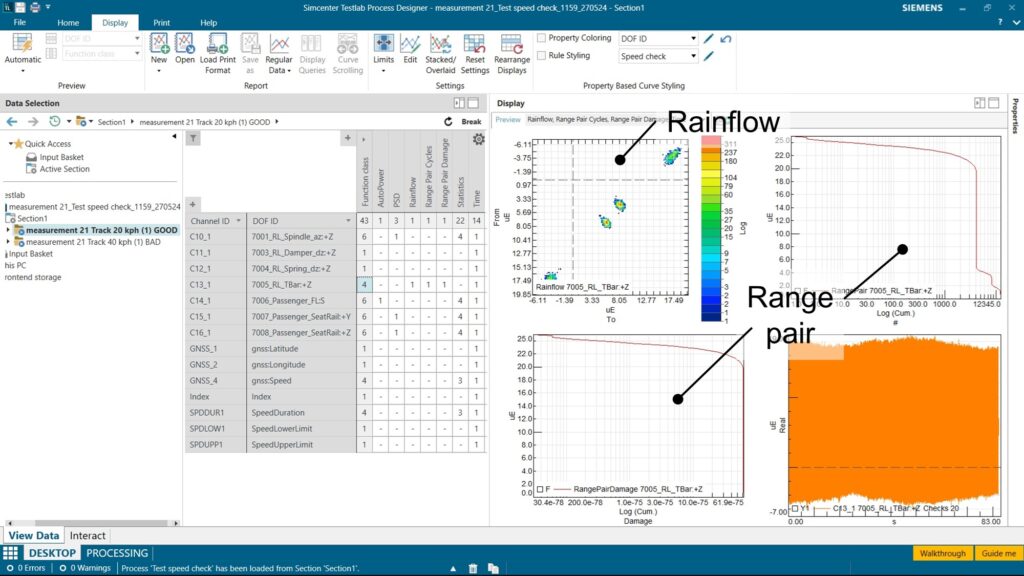

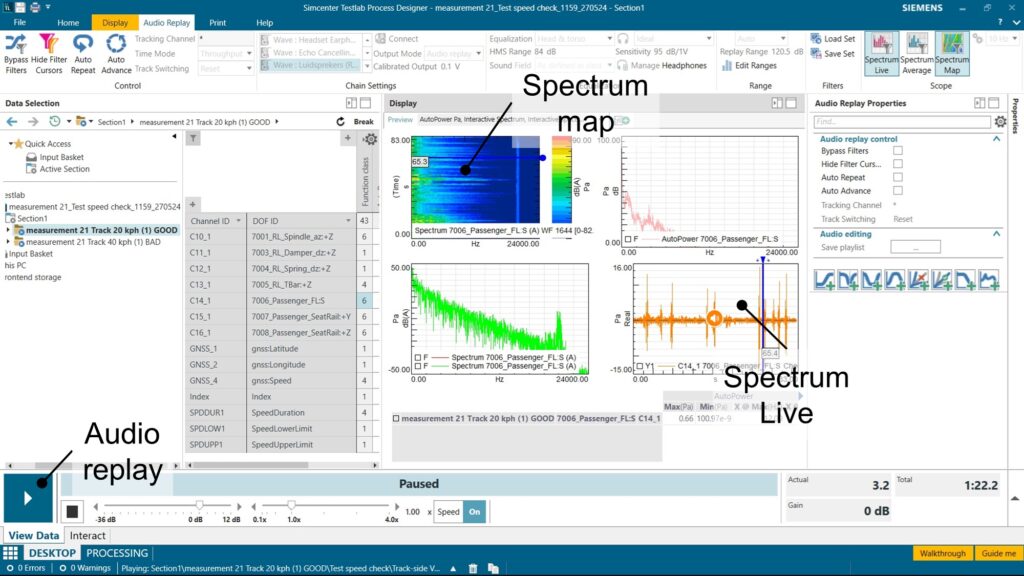

My created process however goes beyond simple detection of road segments. I had integrated a speed check for both sections, verifying if the driver maintained the required speeds of 20 kph and 40 kph, respectively. Additionally, I implemented further post-processing for the different sensors: calculate a spectrum average for the microphone, obtain PSD (Power Spectral Density) for the two accelerometers, perform rainflow and range pair calculations on the strain gauge, and even derive statistics for the GPS speed.

Automating execution

So the vehicle was ready, the Simcenter SCADAS RS was ready and also my process in Simcenter Testlab Neo was ready. With this I could have done a whole sequence of measurements, offload them manually from the Simcenter SCADAS RS and post-process them as next step. The correct segments would have been automatically detected, validated against driving conditions and followed by post-processing of the valid segments.

Nice already, isn’t it? But how about taking it even one step further … by automating all steps!

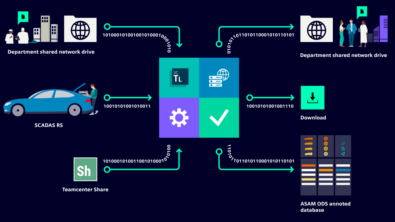

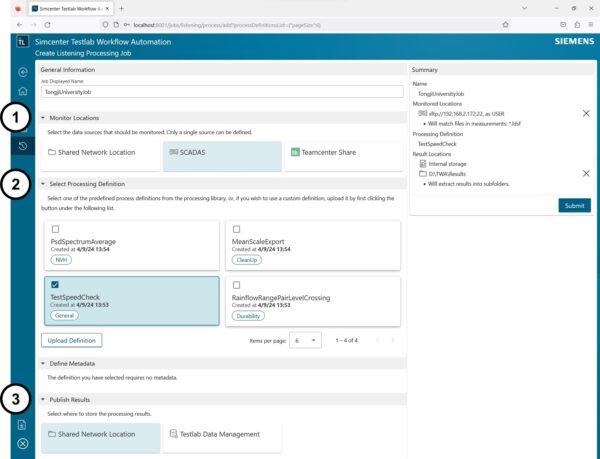

For this, I used Simcenter Testlab Workflow Automation (TWA). In this web-based solution, I only need to define 3 things:

- Which location to monitor for new data. In my case, it was the SSD drive of the Simcenter SCADAS RS REC unit. By means of the IP address of the SCALANCE router, TWA can make a remote connection to the Simcenter SCADAS RS storage.

- How to process the data. This is the Testlab Neo process (.process file) I had prepared here above.

- And finally, where to save (or “publish”) the processed data. I selected a local folder on my PC.

And that’s it! Easy, right?

After submitting this so-called ‘listening job’, TWA immediately made a connection to the Simcenter SCADAS RS and continuously started to listen to what was going on on the internal storage of the Simcenter SCADAS RS. From that moment, it was ready for action …

The demonstration

How did all this work together during the seminar?

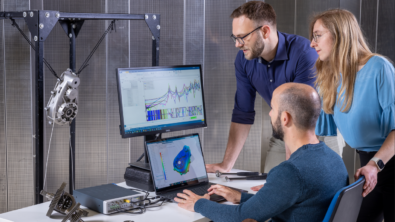

Picture this: I had my PC hooked up to the auditorium projector, and I had multiple windows open. One browser had Simcenter Testlab Workflow Automation (TWA), another had Microsoft Teams with a live video connection inside the vehicle, and yet another browser was connected to the embedded web app of the Simcenter SCADAS RS system.

In the Simcenter SCADAS RS Recorder web app, I created a custom dashboard with real-time features to enhance the monitoring experience. On the left, there was a GPS plot to track the vehicle’s location as they cruised along the road. A speed needle graph allowed me to keep a close eye on their velocity, while a simple time series of the Z signal from the accelerometers provided insight into the vertical load amplitudes on the vehicle.

But here’s where it got even cooler: as it turned out there was a browser installed on the car’s multimedia device allowing us to establish a remote connection with the Simcenter SCADAS RS system by simply entering its IP address. As a result, we could conveniently view the measurement progress directly from the vehicle itself, without any additional screens in the vehicle.

And so, the measurements began! While my colleagues hit the road on the university campus, everyone in the room, including myself, could witness the live action unfolding. It was an immersive experience, with real-time updates on the vehicle and the ongoing measurement.

For the demo’s purpose, I instructed the driver to follow the pre-agreed speed of 20 kph on the first segment. However, on the second segment, I threw them a curveball by asking them to maintain a speed of around 30 kph instead of the expected 40 kph.

Once I saw the driver reach the end of the road after about 1.5 minutes, I manually stopped the measurement using the Simcenter SCADAS RS Recorder web app on my PC. In a matter of seconds, TWA detected the new measurement available on the Simcenter SCADAS RS and initiated the automatic upload process from the vehicle to the designated location on my PC:

Once uploaded, TWA took the measured data and automatically executed the process I had selected. Another brief moment later, the data was processed and saved nicely in the location I had defined.

Now of course, I needed to prove to the audience I was not cheating.

So here is the proof. I presented the Simcenter Testlab project from my laptop, revealing compelling results:

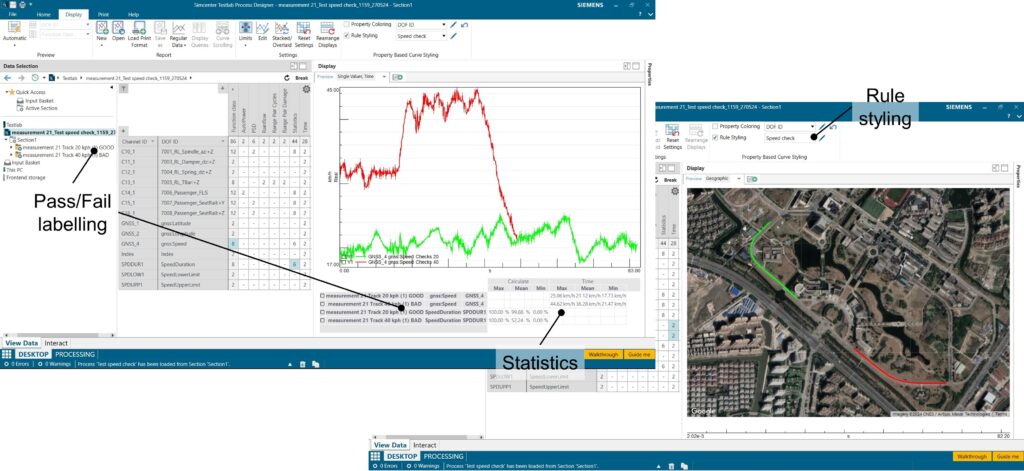

- First, the GPS speed check split the measurement into GOOD and BAD segments. By using the new ‘rule styling’ functionality in Simcenter Testlab Neo, I could also give the GOOD graphs a green color and the BAD ones a red color. Result: good and bad segments are clearly marked with green and red colors.

- The results of the accelerometers (PSD calculations):

- The durability analysis on the strain gauge (rainflow, range pair & damage calculation):

- And finally the average spectrum calculation of the microphone recordings with live audio replay!

The room fell silent for a moment as the audience needed to process this mind-blowing revelation. It was as if they were trying to grasp the magnitude of what had just unfolded before their eyes. Needless to say, this new capability is truly a game changer when it comes to collecting and validating data in the field!

Learn more about automating in-field data collection

If you’re hungry for more information on how to enhance your testing efficiency, look no further than my colleague Agnieszka’s blog. She deep dives into the Simcenter Testlab Workflow Automation service and its profound impact on streamlining testing processes.

Now, I understand if you’re still skeptical. It sounds too good to be true, doesn’t it? But fear not! We’re more than willing to provide you with an onsite demo, right on your own vehicle or machine. Witness first-hand the incredible potential of Simcenter SCADAS RS and Simcenter Testlab Workflow Automation. Prepare to save your company some precious time and money!