Rock and roll with confidence: a recap of Siemens’ recent direct field acoustic noise (DFAN) masterclass

Satellites are inherently delicate and very costly structures. During launch, they experience extremely high levels of vibration and acoustical sound pressure which can severely damage or even destroy components. So it is vital that the whole satellite is thoroughly tested before the launch into space, including its sub-systems. There are no easy repair options.

Direct field acoustic noise (DFAN) testing, an idea to conduct acoustic testing using loudspeakers, which are traditionally performed in expensive and scarce facilities, is really gaining momentum. The method may seem simple at first glance, but test teams first want to understand the finest details behind this innovative technology before applying it to their expensive and unique test item.

Siemens recently organized a masterclass to explain all the steps of a direct field acoustic noise test and highlight state-of-the-art technologies and best practices to handle this test with confidence and utmost efficiency.

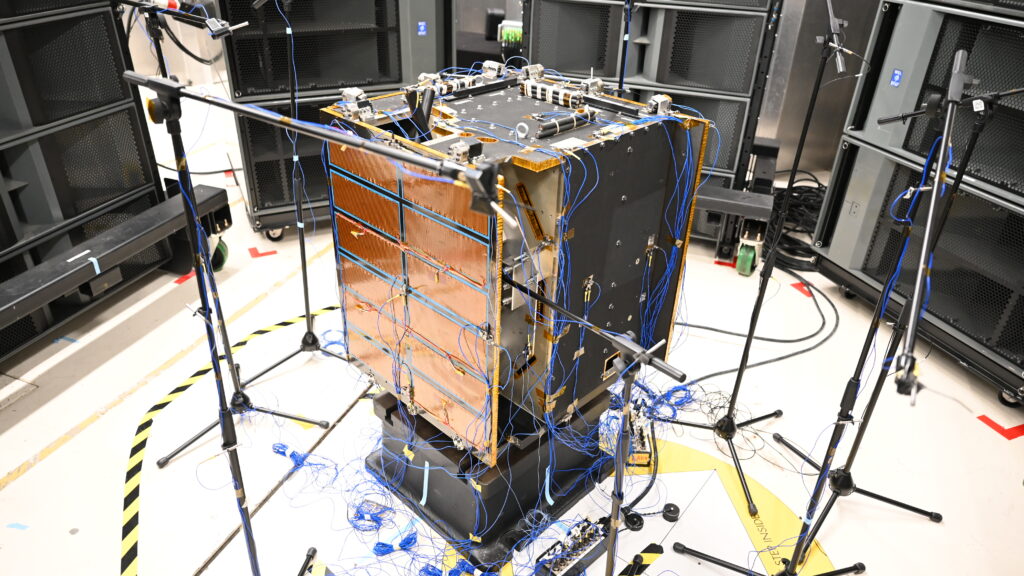

Live DFAN demonstrations on PROBA-V STM model from Redwire Space: from theory to practical application

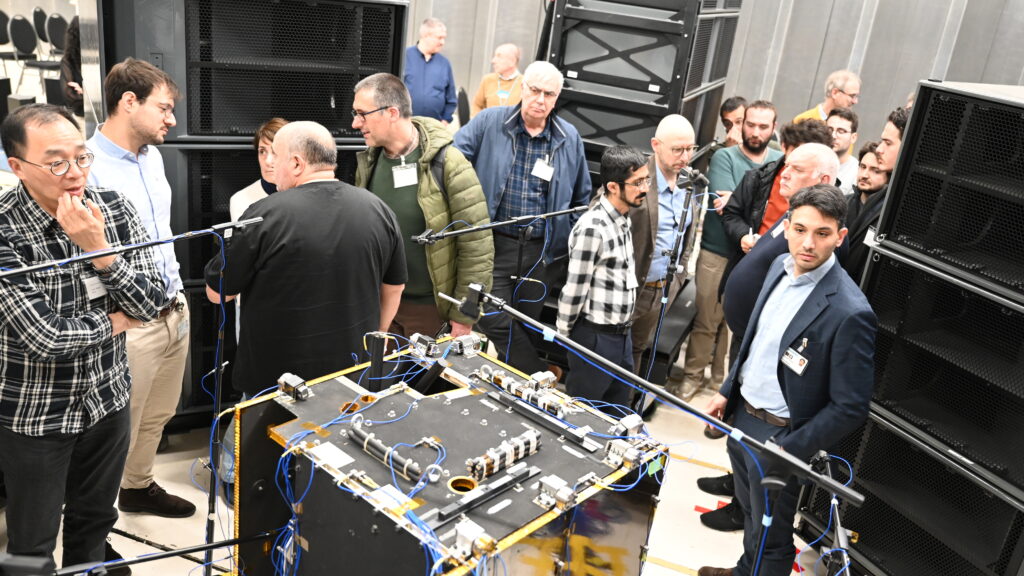

The masterclass brought together over 35 participants from diverse companies and countries, including experts from the aerospace and defense industry such as ESA, Airbus, Thales, CIRA, MBDA, KARI, and other space and military aircraft companies. The event covered a wide range of topics, from theoretical discussions on MIMO random control to live demonstrations of DFAN tests on a real structural model of the PROBA-V satellite.

The masterclass focused on an integrated approach to spacecraft acoustic testing, including test preparation, de-risking using digital twins, validation, execution, and result extraction. Practical aspects such as loudspeaker position, control microphone number and position, monitoring microphone positioning, and response limiting instrumentation were discussed in detail.

The state-of-the-art narrow band MIMO random control algorithm used for achieving the correct data uniformity and diffuse field environment was also presented and demonstrated.

The masterclass featured engaging panel discussions with experts from agencies, institutes, and industry who shared their insights into the application and implications of DFAN technology as an alternative to traditional acoustic testing. Expert guest speakers included Graham Coe from ESA, Christophe Fabries from Thales Alenia Space Toulouse, Vincenzo Di Pietro and Gawra Franceschini from Thales Alenia Space Rome.

Hands-on DFAN activities: learning by doing

There is no better way to learn than by doing the test yourself. During the hands-on activities participants were split into small groups and ran the entire test sequence by themselves. Scaled DFAN setups allowed participants to rehearse the different steps of the test from instrumentation check to actual data collection and analysis with various test setup configurations and settings.

Unique learning and networking opportunity

The masterclass offered attendees valuable networking opportunities, allowing them to connect and exchange ideas. They had the chance to interact with peers from various countries and companies, as well as Siemens experts and guest speakers. These Masterclasses can only happen in close collaboration with our partners: MSI-DFAT, GRAS, and PCB Piezotronics. We are grateful for their contribution, insights and support to show customers how the latest technologies help improve processes. For example, they learned from Alessandro Carrella how MSI-DFAT’s advanced DFAN audio systems and field-proven testing procedures, working with leading hardware and software for data acquisition, acoustic and vibration control from Siemens, create acoustic testing opportunities that surpass the accuracy, acoustic field quality, and overall acoustic level typically achieved in traditional reverberant chambers.

Qualifying next-generation satellites with full confidence

The DFAN masterclass showcased state-of-the-art techniques for confident spacecraft testing, covering the entire process from preparation to reporting. Participants left with new insights, contacts, and the ability to make informed decisions about implementing DFAN technology.

Siemens remains committed to pushing the boundaries of what’s possible in Aerospace and Defense. This event is also an occasion for our research teams to experiment innovative techniques on a DFAN setup with a real satellite structural model. Smart microphone localization procedure is an example of such techniques that can improve test setup preparation by automictically determining the microphone positions in a fast, accurate and cost-effective way.

Don’t miss out on the next DFAN masterclass taking place in the US from October 29th to 31st, 2024! The registration page is now live and ready for you to secure your spot.

Read more about acoustic environment testing