Integration Strategies for Service Engineering

Increase revenue potential and reduce risk with integrated strategies for Service Engineering.

Disconnects in Service Engineering Strategies

In today’s connected world, many companies are approaching the service of their products using various strategies. Some push limited amounts of engineering data forward and rely on their technician’s own knowledge and experience to maintain their physical assets. Some have made the jump straight to IoT and can produce colorful charts and graphs on demand to show service frequency and asset health. Others have built a software stack of solutions to meet their service needs, requiring users to log in to multiple systems and manually piece together service requirements. What are these approaches missing, and what can you do to increase your service revenue potential and reduce risk?

There is no single and perfect integration strategy for all companies, but there are some key connection points required to truly satisfy the needs of service in a productive and cost-effective manner. I’ll get into more details to highlight methods that can break down the walls between functional domains that often lead to serious disconnects in service engineering.

Service Engineering and Service Operations Together

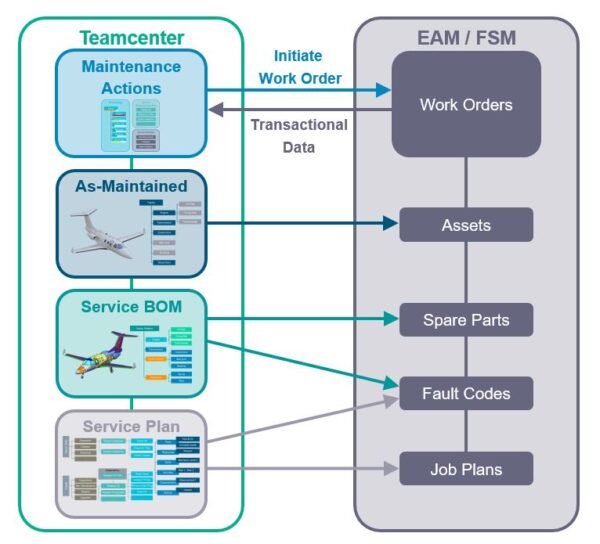

Let’s start with the importance of an integration strategy that brings together the worlds of Service Engineering and Service Operations. The Siemens’ Teamcenter (PLM) integration with IBM’s Maximo (EAM) is a fine example of this. The integration leverages the strengths of the PLM system to author service data based on design and manufacturing knowledge, while maintaining configuration control of the product. The output of service data authoring in PLM is shared with the Service Operation system, allowing it to do what it does best, manage the Service Work Order (SWO) and related schedules, resources, and costs. This includes sharing parts lists, work cards, tech pubs, upgrades, and As-Built details, including non-conformances.

Once service data has been shared and SWOs are executed, the service engineering solution should provide the ability to send relevant information back to the PLM system to be used in the service engineering change process. With information from the point of maintenance, Engineers can better understand how the asset is performing, where and when failures are occurring, and which parts and processes are exceeding expectations. With the right integration strategy, this provision of up-to-date service information from the point of maintenance will accelerate designs of upgrades, changes to parts and processes, and identification of bad actors or suppliers – ultimately leading to profitable product service.

Physical Asset Configuration Management

Look for service engineering solutions that provide complete visibility into your physical asset configurations. This will ensure that service technicians have the right parts and the right instructions to perform asset maintenance. For example, let’s say you purchase 10 identical CNC machines. Once you start using the machines, they quickly become unique assets in your inventory based on usage and maintenance schedules. In some cases, the machines arrive on site with unique configurations due to deviations and non-conformances during the manufacturing process. Understanding these non-conformances and asset history is critical, as this can affect maintenance cycles and life spans, or require additional maintenance actions that were not part of the original plan.

Proactive Monitoring and Assessment to Reduce Risk

End-to-end integration of service data with a common taxonomy enables the true value of an IoT based performance and tech health monitoring system. Connecting your solution to IoT for proactive planning will enable asset health and performance monitoring (along with AI and predictive capabilities). Leveraging IoT and Operational Technology (OT) data to track the performance of your assets and predict the best time for maintenance will help to avoid catastrophic failures. Pushing ‘design for service’ further into the early product design phases is also key to reducing risk. Reliability and risk analysis identifies critical service components, redundant system recommendations, key characteristics and locations for monitoring, recommended frequencies for periodic maintenance, and more. These results need to feed into the Design BOM, Service BOM, Service Requirements, Logistics, and Provisioning of a product, and ultimately into the Service Operations and Performance areas. Each of these areas should speak the same language and not change the terminology from upstream processes. For example, let’s say a pump is analyzed against 5 failure modes. Service requirements and spare parts are identified to resolve each of those 5 failure modes, converting failure modes into equivalent failure codes and identifying the work required to resolve each failure code. Feeding information to the Field, and then building upon it as it travels, is important. Equally important is reversing that path and bringing information from the Field back to Engineering to close the product and service loop.

Service engineering best practice requires a common taxonomy for engineering data consistency across the product and service lifecycles. If you want to efficiently close the digital product and service loop, you can’t call something an apple during design, and then call it a banana in the field.

Chris Stecki, PHM Technologies

Integration Strategies Lead to More Revenue

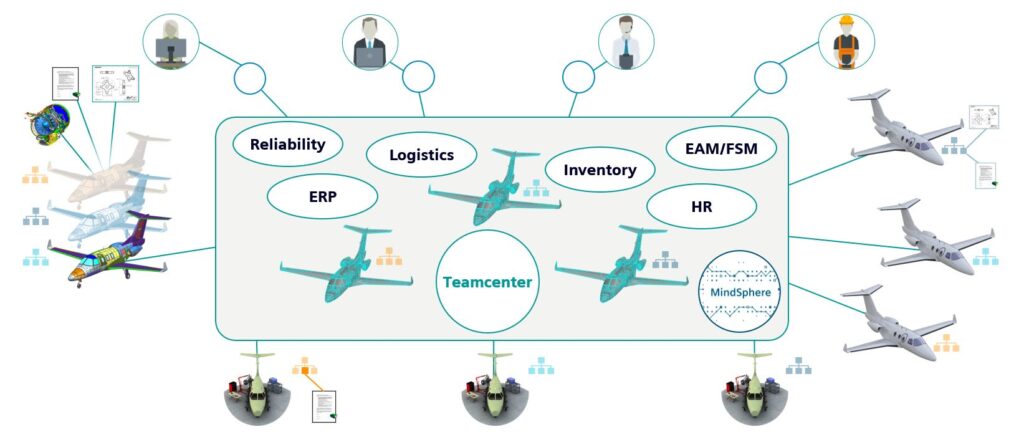

In my experience, I’ve worked with companies who focus on ERP, Inventory, and HR integrations to address their service engineering initiatives, and initially, they leave out operations, noting it’s too costly to integrate to the disconnected systems. Eventually, the companies discover that with the right integration strategy, connecting the disconnected operations will result in process improvements and cost savings while generating more revenue.

A successful service integration strategy must leverage technology delivered on a product lifecycle management (PLM) backbone with workflow, visualization, configuration, change and BOM management, and other core PLM capabilities. This environment should include System Models, Design/Engineering BOM, Manufacturing BOM, Service BOM, and Physical Structures (serialized tracking of As-Built, As-Commissioned, As-Maintained, etc.). The right PLM solution, such as Teamcenter, should connect service related information and allow it to flow freely to the other integrated solutions, upstream and downstream.

The Right Integration Strategy with Teamcenter

If you can’t identify asset content, do you know how it should perform or how it should be maintained? Do you have the right parts in inventory for the current asset configurations? Do you have the right skills and certifications in the workforce to maintain the assets? Is your IoT solution tracking the right data? Having the right integration strategy helps you answer these questions. What sets Teamcenter apart from other PLM and ERP systems is its ability to track the physical structure of the asset – not what the Engineering BOM or Manufacturing BOM says should be there, but what is installed. After all, once the asset is built and enters production, it can be modified with non-conformances, deviations, spare parts, upgrades, etc. You may no longer have a 1 to 1 match of the EBOM. Maintaining design and service data together in Teamcenter enables you to validate what’s happening in the field, identify upgrade candidates, and leverage direct links to Engineering and Manufacturing data for analysis. Integrating with MES, EAM, CMMS, and FSM solutions enable the capturing of the physical structure at the right stages in the product lifecycle. Without this, it’s difficult to know what you are monitoring or servicing.

So Many Possibilities

Imagine eliminating the need for your technicians to make multiple onsite trips to resolve an asset issue. Imagine your technicians no longer having to call in for remote assistance due to lack of information or instructions. Think about technicians becoming an extension of your sales teams by enabling them to sell an upgrade they know will work with the customers current asset configuration. With a fully integrated solution, technicians can service an asset with the confidence of knowing they have the right parts, the right configuration details, the right work instructions, and the right technical data to get the job done right the first time.

Be sure to catch the virtual Service Lifecycle Management seminar series to learn how to turn product complexity into a competitive advantage. In this multi-part series, we will focus on challenges you may be facing in the service lifecycle domain, and how Siemens software can help.