Multi-robot work cell programming with KineoWorks

Industrial robotics applications continue to grow dramatically as they meet the demand for automating manufacturing operations to scale-up production, improve quality, and safeguard against shortages of on-premise workers. To meet this increasing demand for automation, robot work cells are becoming more sophisticated with multiple articulated robots working in harmony to perform a wide range of simultaneous manufacturing operations including component assembly, welding, spraying and inspection.

These multi robot systems bring new technical challenges in process-planning. Each robot needs to perform its assigned tasks as efficiently as possible in what is often a cluttered environment of moving parts and machinery. In many cases, the operating range of individual robots will overlap, creating a critical requirement to ensure each robot avoids collisions with other robots in the working environment.

Planning the collision-free operation of multiple robots without compromising on productivity is a complex task. While it’s possible to safeguard against collisions by restricting each robot’s operating zone, or by pausing some simultaneous operations, these measures increase robot cycle times and negatively impact the cell’s productivity. As a result, it can take weeks to manually teach multiple robots to complete efficient, collision-free manufacturing processes.

Automated collision-free coordination of two or more industrial robots

KineoWorks now includes new process-planning technology that automatically coordinates the simultaneous, collision-free motion of multiple robots. The result is a dramatic reduction in the time it will take to program efficient multi robot work cells.

The new solution for multi robot simulation builds on KineoWorks’ industry-proven capability in motion planning for individual robots: KineoWorks is already widely adopted to compute collision-free robot trajectories, automatically optimizing them with respect to cycle time, energy efficiency, sequence ordering, preferred tool orientation, and related manufacturing criteria.

KineoWorks will now consolidate and collectively analyse the trajectories of each robot in the work cell. The individual trajectories are updated with adjusted waypoints or waiting times to coordinate collision-free simultaneous operations across all robots in the cell.

The result? With KineoWorks, programming collision-free multi robot operations is reduced to a matter of hours.

Universal multi-robot simulation software and simplified work cell prototyping

KineoWorks is a software solution that is designed for integration into any robot simulation and control system. For example, KineoWorks couples with proprietary Robot Controller Systems (RCS) to compute trajectories that are directly compatible with a wide range of manufacturers’ robots and includes its own RCS module which makes it possible to evaluate robot controller trajectories independently of a specific vendor’s RCS module.

Siemens Digital Industries Software also offers you complementary solutions to extend and accelerate your robot simulation and control applications:

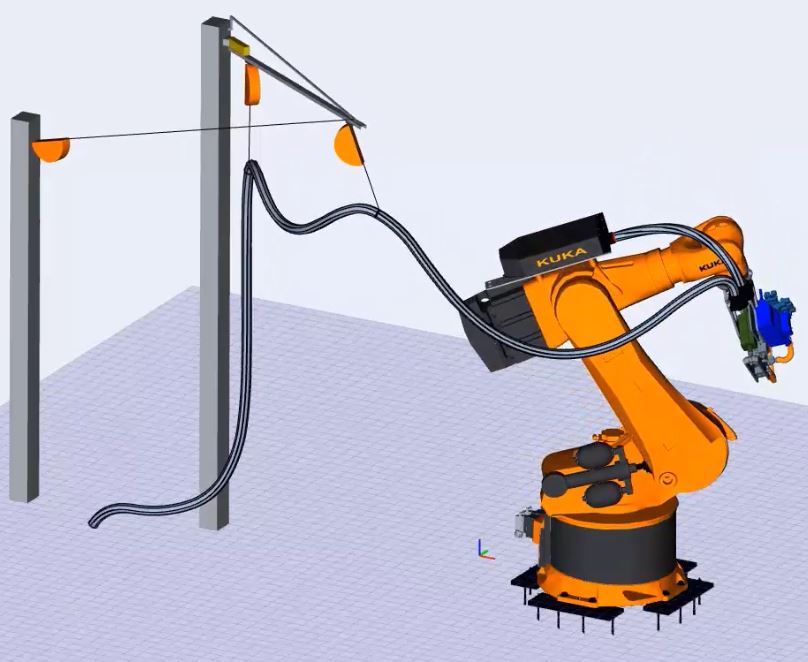

- Kineo Flexible Cables – model and predict the behavior of electric, pneumatic and hydraulic robot cables / dress-packs on the factory floor.

- KineoWorks Interact – build a rich Graphical User Interface for your software applications quickly and easily with tools for 3D visualization, user-interaction, data import/export, etc. with the minimum of coding.

- Kineo Collision Detector – perform high speed collision analysis on mesh surfaces and point cloud data in motion simulation environments such as robotics simulation.

Further information

Learn about our latest innovation for robot dresspack simulation