The Quadcopter Story with the Digital Machine Shop

What does it take to manufacture a quadcopter? How does the Digital Machine Shop transform the manufacturing process?

Find the answers in a blog series written by our experts that highlight the advanced capabilities of NX software that drive the entire manufacturing process – from part and mold design to CNC programming and machining to additive manufacturing and quality inspection.

The Quadcopter Blog Series

The Digital Machine Shop: Making an Idea Go Airborne

The introductory blog features Armin Gruenewald, Vice President of Strategy & Portfolio Management at Siemens Digital Industries Software, as he kicks off this series on the creation of a quadcopter mold. Set as a way of illustrating the unique benefits of the digital machine shop, the following blog posts will be written by Siemens domain experts, starting with mold design and ending up on the shop floor.

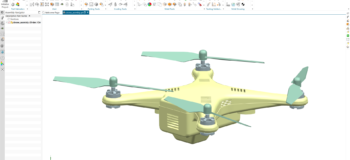

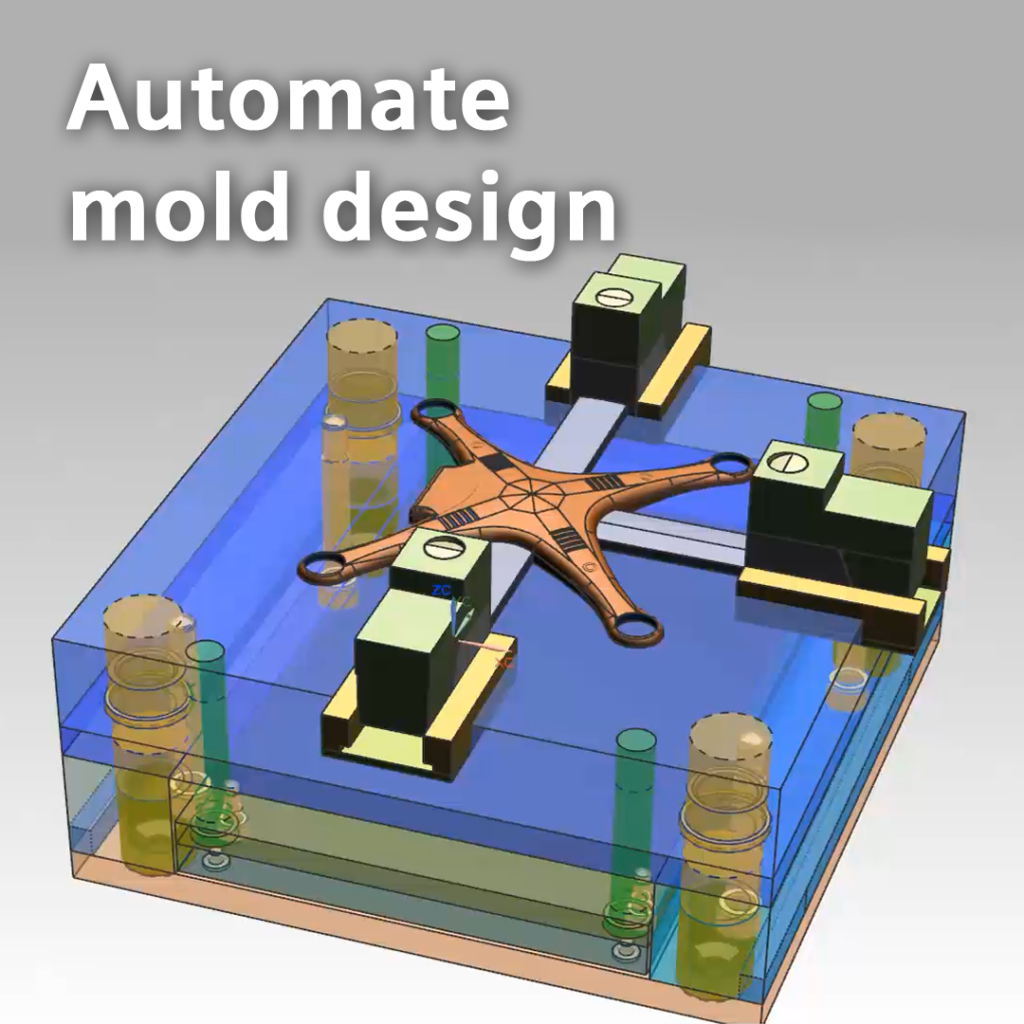

Mold Design: The Quadcopter Launch Begins

In the second blog in the series, learn how to automate mold design, starting with the digital twin. Himanshu Iyer, a member of the Product Marketing team of NX, will use the injection molded cover of a quadcopter to illustrate the wealth of opportunities made possible by a digital machine shop. He will walk you through the mold design process for the quadcopter mold, from the CAD data to mold assembly.

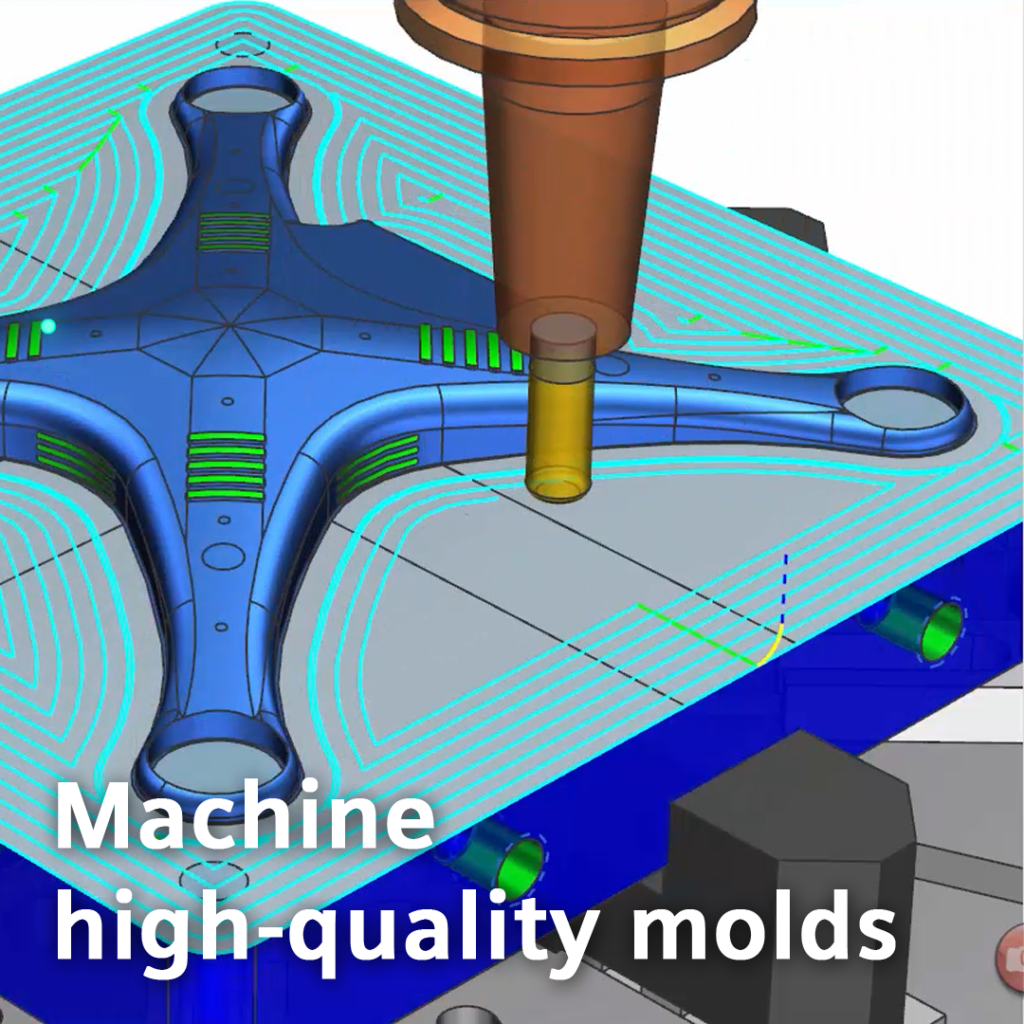

Moving into Metal: CNC Programming of the Quadcopter’s Molds

The third blog has the mold for the plastic top of the quadcopter moving from design into manufacturing. Lars Okkels, a CAM Consultant at Siemens Digital Industries Software, demonstrates how he developed advanced machining processes that were used to manufacture the key mold components. You’ll look at core and cavity programming, mold plate programming, process validation, postprocessing, and the creation of shop floor documentation.

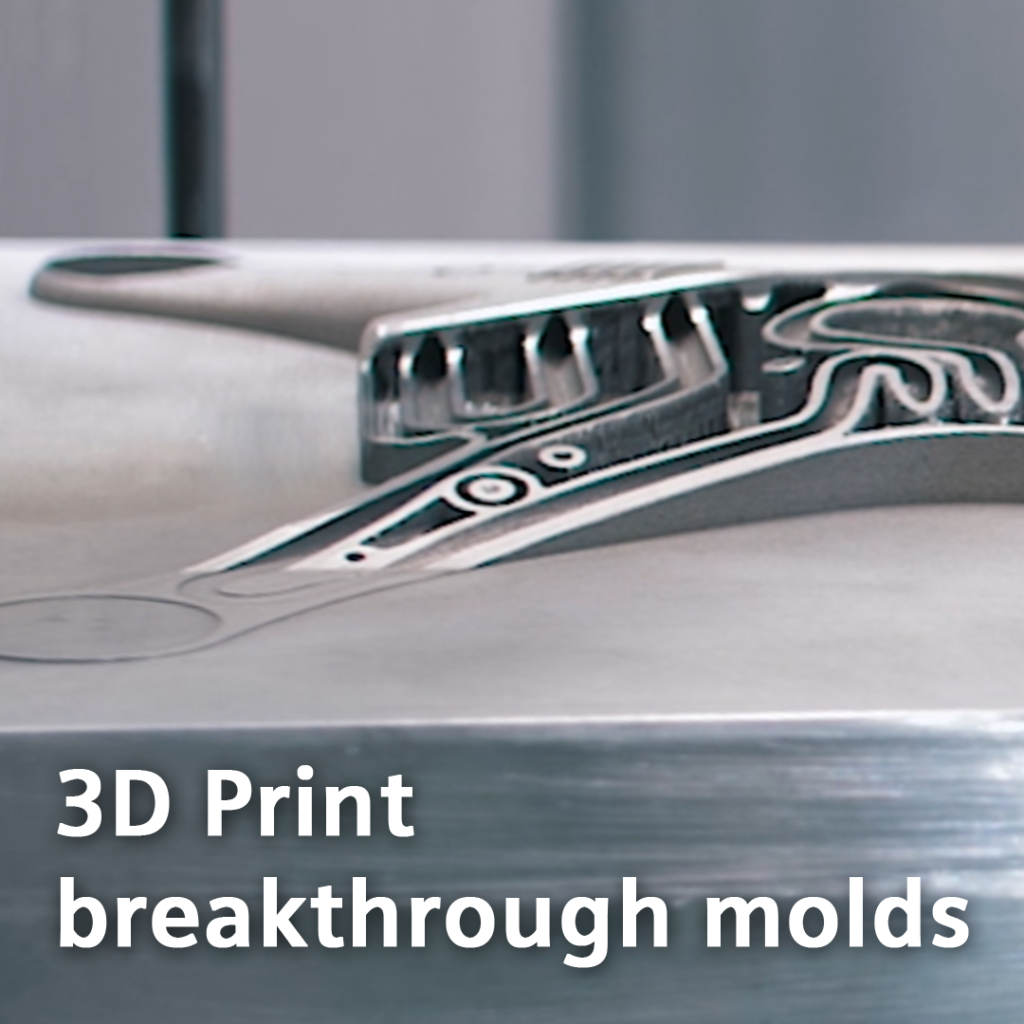

Getting Closer to Launch: Additive Manufacturing for the Quadcopter Mold

In the fourth blog, Ashley Eckhoff, a member of the Additive Manufacturing Group at Siemens Digital Industries Software, focuses on the role of additive manufacturing for molds when creating the quadcopter. You will learn how additive manufacturing was used to create the conformational cooling channels on the mold, which can significantly improve the molding process efficiency.

Making Sure We Got It Right: CMM Inspection Programming for the Quadcopter Mold

The fifth blog looks at the inspection process of the quadcopter. John Zhang, a Dimensional Management Consultant at Siemens Digital Industries Software, shares how the same digital thread we’ve followed through the design and manufacturing of the quadcopter mold continues seamlessly into another critical operation – part inspection with NX CMM Inspection Programming.

Getting Real: Shop Floor Connectivity

In the final blog, Corsin Buerer, the head of Production and Quality Software at Siemens Digital Industries Software, discusses shop floor connectivity, specifically how the work done in the previous stages of the quadcopter project made its way to the people and machines who turned the mold design into an actual mold. You’ll learn the benefits of going digital – with improved part quality and shorter time-to-market thanks to NX software.

The Digital Journey of the Modern Machine Shop

Learn to make manufacturing lead time an asset and embark on a path to profitability with the digital machine shop in our eBook.