What’s New in NX | June 2023 | NX Mold, Tool & Die

Mold, Tool & Die Manufacturing

Tooling plays a key role in the creation of new products. Every toolmaker on the planet needs to overcome major challenges on a day-to-day basis. New product complexity, increases in quality requirements, and supply chain issues being some of the most important challenges to overcome. We’re seeing that tooling manufacturers are intending to invest in more CNC automation to improve quality and lead time. And this is where NX™ software Mold, Tool & Die Manufacturing.

What is Mold, Tool & Die Manufacturing?

NX delivers a complete CAD/CAM solution for the design and manufacturing of molds, dies and electrodes. The design capabilities within NX provide automation and process simulation to ensure first-time quality.

Let’s dive into the rest of the blog 👇

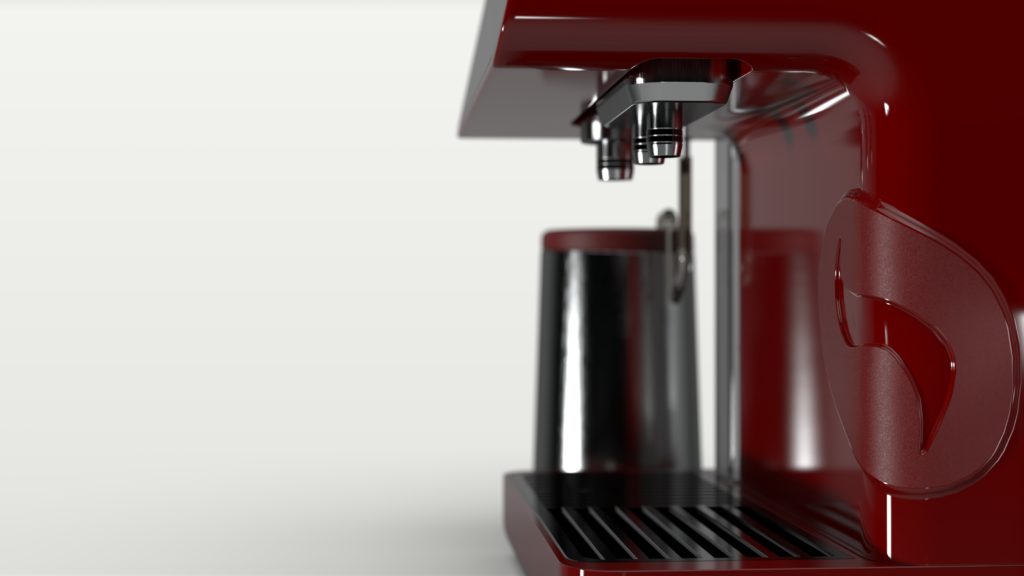

Throughout the course of the blog, everything mentioned will be in context with this coffee machine. We’ll be showing you elements of a typical workflow within NX to prep the coffee machine ready for manufacturing. We’ll show you a range of best practices, existing functionality and new tools to ensure the process runs smoothly.

Bringing the Mold into CAM

We want to bring the mold for the coffee machine into the CAM environment. Once done, the first thing to notice is this specific model has a lot of intricate details that we don’t want to machine using milling operations, or that we simply can’t machine. To remove these features, we’ll use Synchronous Modeling, directly in NX. As a reminder, Synchronous Modeling enables the direct manipulation of solid and surface geometry without the need to fully understand how a model is constructed. It’s an efficient way to prepare part models for NC programming.

In this use case, we’re looking at removing faces from the coffee machine. Changes we make to the original model will propagate through digital thread, and automatically update the CAM setup.

Cloud Connect Tool Manager

NX makes it possible to create machining operations for a range of use cases, and this is made possible by Cloud Connect Tool Manager; a brand new feature added to the June 2023 release of NX. Cloud Connect Tool Manager allows us to find the right tool for the job, which can be found from an extensive, easy-to-use library of milling tools. What’s more, the tool’s interface is simple, effective and easy to use. Additionally, cutting tool catalogs can imported directly into your library.

Did you know?

If you need a tool that’s not in the Cloud Connect Tool Manager Library, you can create one from scratch. Information such as name, description and tool number can be captured, whilst all the inputs for the cutter and shank can be tweaked directly on the screen.

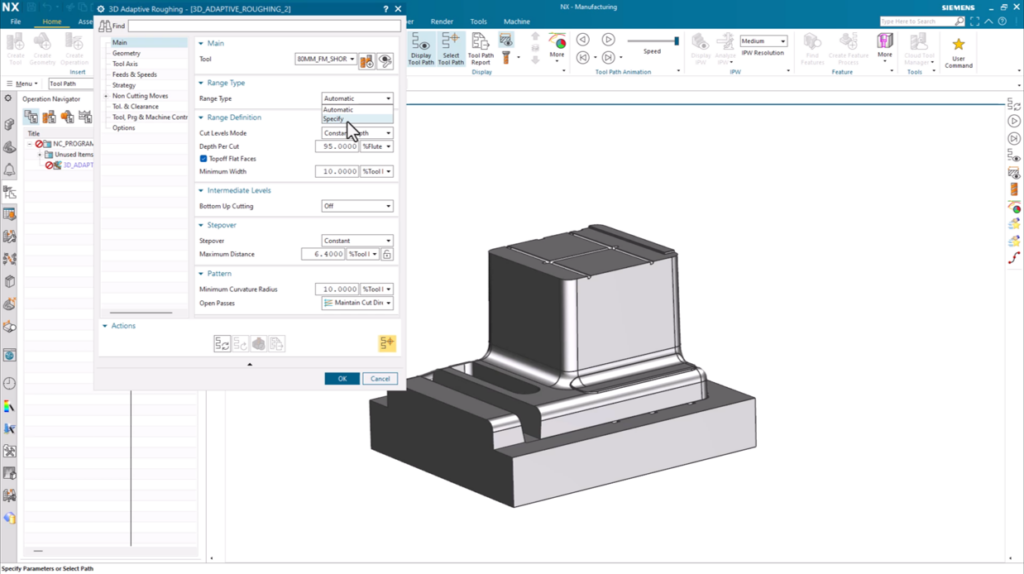

3D Adaptive Roughing

3D Adaptive Roughing is the successor to the Adaptive Milling operation, and creates highly efficient tool-paths to rapidly remove the bulk of the material. In the June 2023 release of NX, we’ve improved tool-path generation performance and the holder collision avoidance functionality. Additionally, it can also automatically detect and machine any flat surfaces.

What we wanted to achieve for this release of NX was to reduce the time taken to generate the high-speed machining tool-path. Our studies suggest this ultra-fast roughing method can reduce machining time by more than 60%!

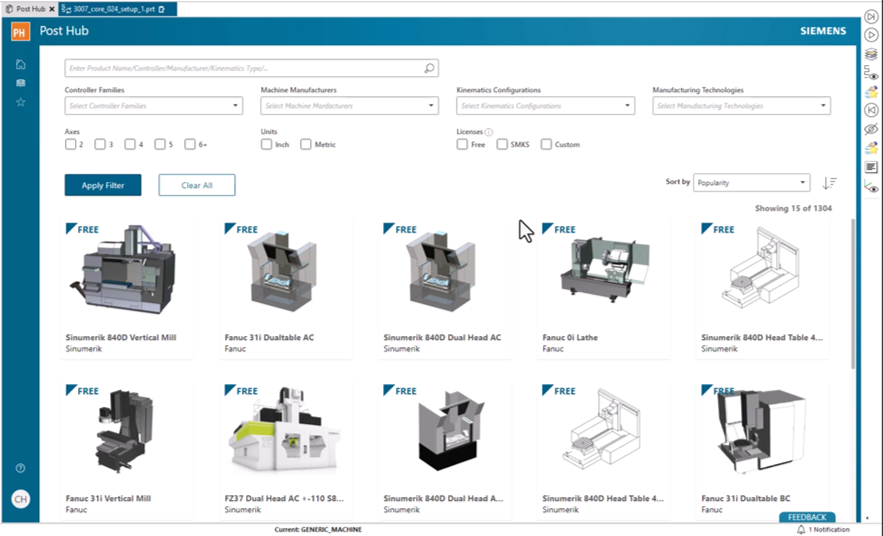

Downloading an SMK from Post Hub

Another important step to consider is the ability to simulate the machining process and generate the program to drive the CNC machines on the shop floor. This is where we bring in an SMK, or smart machine kit. This is a fully functioning Simulation Kit, created and developed by Siemens, and can be accessed through Post Hub

What is Post Hub?

An extensive cloud-based library of machine kits, post-processors, training material, and CAM add-ons. The library includes more than 1200 processors and 100 SMK’s

Machining simulation

Next, we take a look at machining simulation within NX. It’s important to simulate the machining process using the G-code driven simulation in NX CAM. Using the digital twin technology, it’s possible to accurately display the motion driven from the CNC program. The accurate simulation helps us avoid errors in the production for the coffee machine. It not only ensures safe operations, but also speed up the setup, maximizes machine utilization and reduces energy consumption.

Watch the full Mold, Tool and Die Manufacturing video ▶️

Be sure to check out the full video below to learn about everything in the blog, plus more.

You can access all the manufacturing capabilities through our Value-Based Licensing; an extension of existing NX software packages. It’s a scalable, cost effective way for you to take advantage of NX’s industry leading manufacturing capabilities.

Additionally, check out our other NX related content below. Thanks for reading.