NX | Tips and Tricks | Surface Quality Tools

Our latest NX™ software Tips and Tricks video demonstrates the latest improvements to surface quality tools, specifically in Face Analysis objects.

The Face Shape Group offers a number of analysis tests to ensure your parts and assemblies meet company and industry standards. In this blog, we will dive into the surface quality tools available in NX, and how to use them to elevate your designs.

What are surface quality tools

Surface quality inspections are an important part of producing a durable design. High quality surface finishes enhance surface electrical conductivities, strengthen products against wear while reducing friction, and even play a role in corrosion and chemical resistance. There is also an additional aesthetic appeal to products that have a smooth contour with well-placed angles.

NX has a dedicated group under the Analysis tab called Face Shape that contains different tools and tests to provide a comprehensive overview of your models and designs. In this group, some of the different tests include Highlight Lines, Draft Analysis, and Face Curvature. All of these tests have their own individual benefits and values, offering great opportunity to improve your models and designs.

In this latest edition of the NX Tips and Tricks series, we explored a few of these tools. Lets take a deeper look at what’s in this episode.

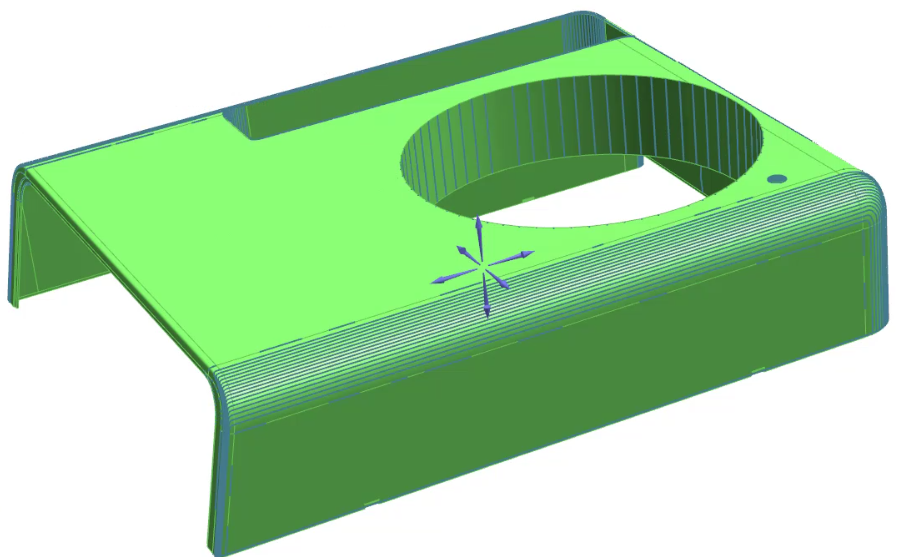

Highlight Lines

Producing highlight lines is a great tool to examine the quality of your product’s design. You have the option to explore reflection lines, projection lines, and isoclines to investigate what your design looks like under varying light conditions.

Visualizing these highlight lines will make many types of surface irregularities easily apparent. To perform these analysis tests, begin by selecting the faces you want to investigate, and then choose a light setup to fit product and design needs.

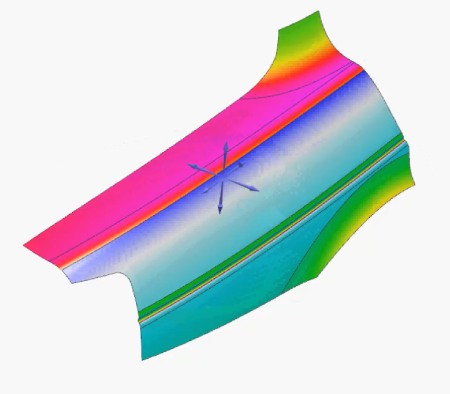

Radius and Slope Analysis

In addition to the variety of highlight line options, there are several different face analysis tools available within NX. These tools including slope, radius, and distance, will all display a color scale gradient on the face of the model that demonstrates the different respective values which were tested.

When performing these tests, there is a color scale key along the right of the screen to provide a better understanding of the values displayed. As with the highlight lines, the different face analysis tools provide excellent resources to analyze your parts and assemblies for specific design requirements.

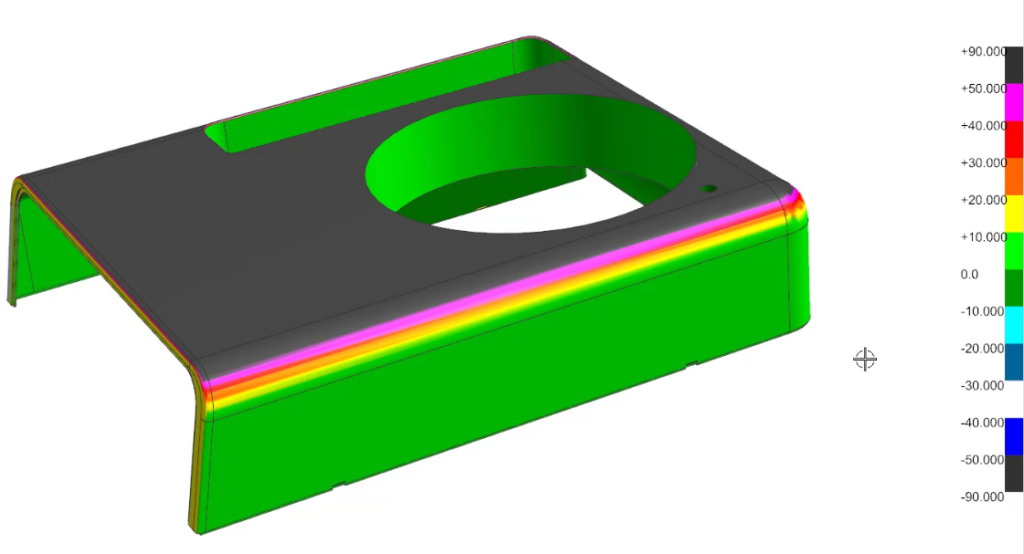

Personalize color schemes and gradients

One key tool to optimize your face analysis tests is the ability to customize the color scheme and data range for your design evaluations. This is a great way to organize values into ranges that are acceptable, unacceptable, and values somewhere in between.

To do this, you select the “User Defined” option under the Data Range tab and then choose the number of colors to display. After this, you can now select the value each color range is organized between, and the associated color.

One useful trick when doing this is to organize your model into three color tiers: one for acceptable values, a middle tier for questionable values, and a color scheme for unacceptable values.