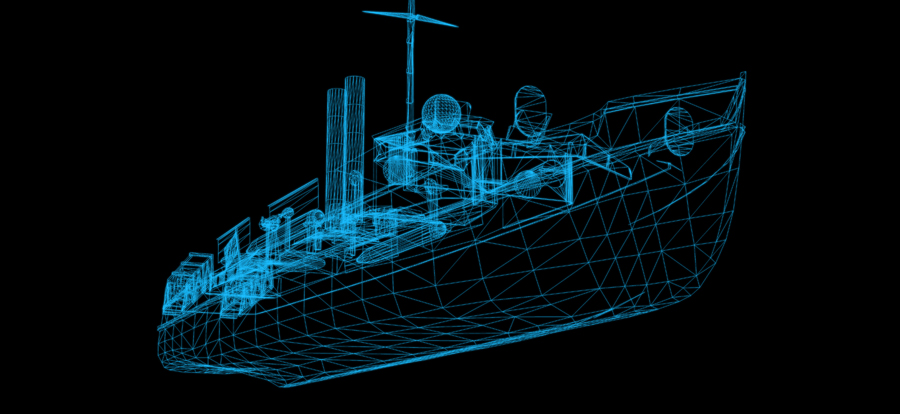

Five reasons to adopt a simulation-driven approach to the ship design process

We’ve discussed before the need for naval architects to move away from the design spiral method of designing ships. Developed in 1959, this method no longer best serves the marine industry’s needs. There is greater pressure than ever to identify efficient designs in increasingly shorter timeframes. The industry has no choice but to adapt.

However, we know that implementing new systems and processes isn’t something done lightly. Adopting a new working model requires investment, and any investment requires justification. Here, we have five major reasons to transition to a simulation-driven ship design process.

#1 It takes advantage of new digital technology

Technology has come a long way since the design spiral method was first adopted. With new technology and tools comes a new way of working. Simulation technologies can revolutionize the ship design process by breaking down silos between teams and creating an integrated design environment where data is easily transformed and shared.

#2 A simulation-driven design approach minimizes risk

The marine industry is under pressure to significantly cut its CO2 emissions in the coming decades. Missing performance targets increases risk for shipyards. Furthermore, the design spiral creates siloed work environments using unconnected tools, increasing the time needed to complete all phases of design work. Once a design has been started and committed to, it’s often more costly to pivot to a new design than to attempt to refine the original design. This also adds risk for shipyards.

With simulation-driven design, you have a streamlined process where tools are compatible across different phases of design. Teams can work in tandem, bringing all the design phases together so they can interact seamlessly and reduce risk for the enterprise.

#3 It reduces costs outside the ship design process

The design spiral is a very rigid process, with each step building on the previous ones. As we mentioned, this structure makes it difficult to make substantial adjustments to designs past a certain point. Yet the design phase of shipbuilding has the greatest impact on reducing building costs.

By streamlining the ship design process and giving teams the ability to work together without friction, they can minimize costly design mistakes. Additionally, using simulation technologies allows teams to evaluate which designs will meet performance requirements while controlling costs.

#4 Simulation-driven ship design increases confidence in performance

Using a single, fully integrated environment where all necessary data is located, naval architects can evaluate design variants from the earliest phases of design. They can perform analyses early in the ship design process to evaluate how changes impact different facets of performance. By the time construction begins, they can have greater confidence that the performance targets they designed and tested for will be met.

#5 Simulation-driven ship design can drive innovation

Perhaps the most significant impact of a transition to simulation-driven ship design is the opportunities it creates for innovation. The design spiral has made it difficult to push for new designs as the time-consuming process of reviewing and validating designs and data across disconnected teams discourages spending more precious time going back to the drawing board.

Simulation and the use of an integrated design environment creates space for naval architects to explore hundreds of designs without wasting person-hours. Once a simulation has been set up, the process is driven automatically through computers, freeing up the architect to work on designs and analysis.

The benefits of a new ship design process

As trends in sustainability and the global economy continue to put pressure on the global marine industry, it’ll become more important than ever for naval architects and shipyards to embrace the new technology and paradigms that are revolutionizing the way ships are designed and built. Simulation is already proving to be vital in minimizing risk, reducing costs, bettering performance and inspiring greater innovation.

To learn more about implementing a simulation-driven approach to ship design, download our free white paper.