On-demand webinars: Learn how simulation accelerates gas turbine innovation

In today’s pressure-filled energy market, gas turbine efficiency and emission requirements are higher than ever. To increase profits while reducing costs, gas turbine manufacturers must design better, stronger and safer technologies. They must do this in faster timeframes using smaller teams.

Siemens makes these demanding goals achievable with the power of multiphysics simulation and the digital twin. Learn how our disruptive innovation solutions uniquely benefit gas turbine manufacturers by watching these four on-demand webinars.

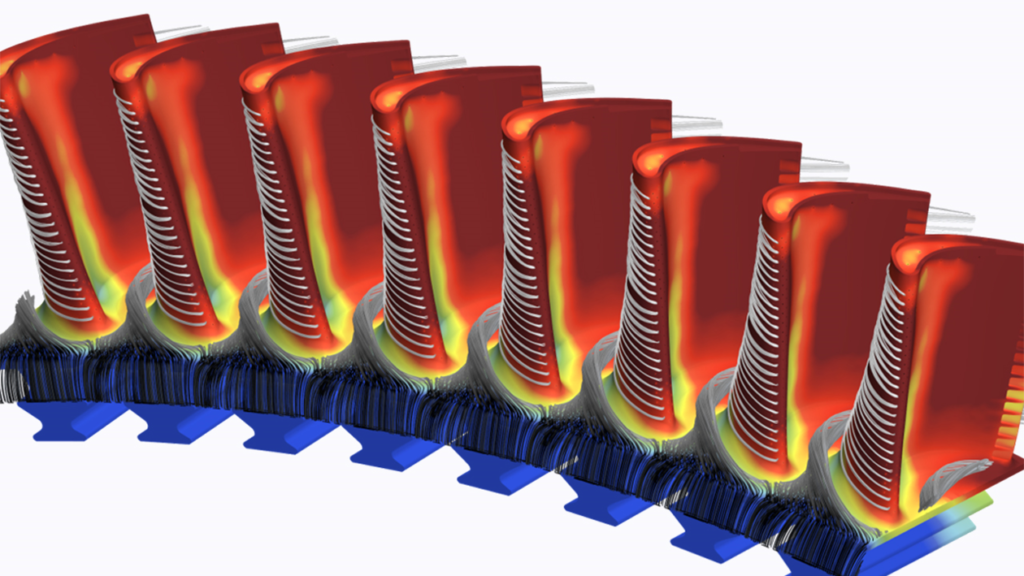

High fidelity aerodynamic simulation for gas turbine design

Discover how Siemens Energy takes simulation fidelity to the next level by combining results from different disciplines inside a single tool. By linking combustion and blade cooling predictions or aerodynamic and aero-mechanic responses, the realism and accuracy of results improves. Learn how this combined approach increases understanding of turbine performance while bringing improved gas turbine designs to market.

Predict blade aerodynamic performance with confidence

Learn how to predict turbine blade aerodynamic performance faster and more accurately using our computational fluid dynamics (CFD) simulation solutions. Hear directly from Siemens’ specialists on new features designed specifically for turbomachinery applications and learn how to apply them to turbine and compressor simulations. In today’s rapidly-changing market, only the best simulation tools will do.

Learn how B&B-AGEMA uses CFD simulation in their combustor design process

Combustor design relies on CFD simulation to give insight into flames, mixing, temperatures and emissions. In this webinar, B&B-AGEMA presents results from their latest combustor simulations. Discover how they use CFD to design combustors, optimize monitoring equipment and gain improved understanding of hydrogen combustion.

Speed up the hot to cold blade conversion process

Determining efficient blade shapes is critical for improving turbine designs. Compressor blade geometry first defines the operating hot shape. This must be reverse-engineered to the cold blade shape before manufacturing and often requires an iterative finite element approach. In this webinar, we present how Siemens Energy uses Simcenter to perform hot to cold conversion in a single analysis step. This approach is up to five times quicker than a standard iterative method with the same level of accuracy.

Comments

Leave a Reply

You must be logged in to post a comment.

I have tried Siemens products and they have the best ones. https://www.cintaspartnerconnect.online/