On-demand Webinar: Deploying Digital Twins into Energy and Process Business Operations

As complexity and competition increase, energy and process companies must continually boost innovation while reducing costs. A powerful innovation solution is to incorporate physics-based simulation into the digital twin, which empowers engineers to determine optimal equipment designs before a unit enters production.

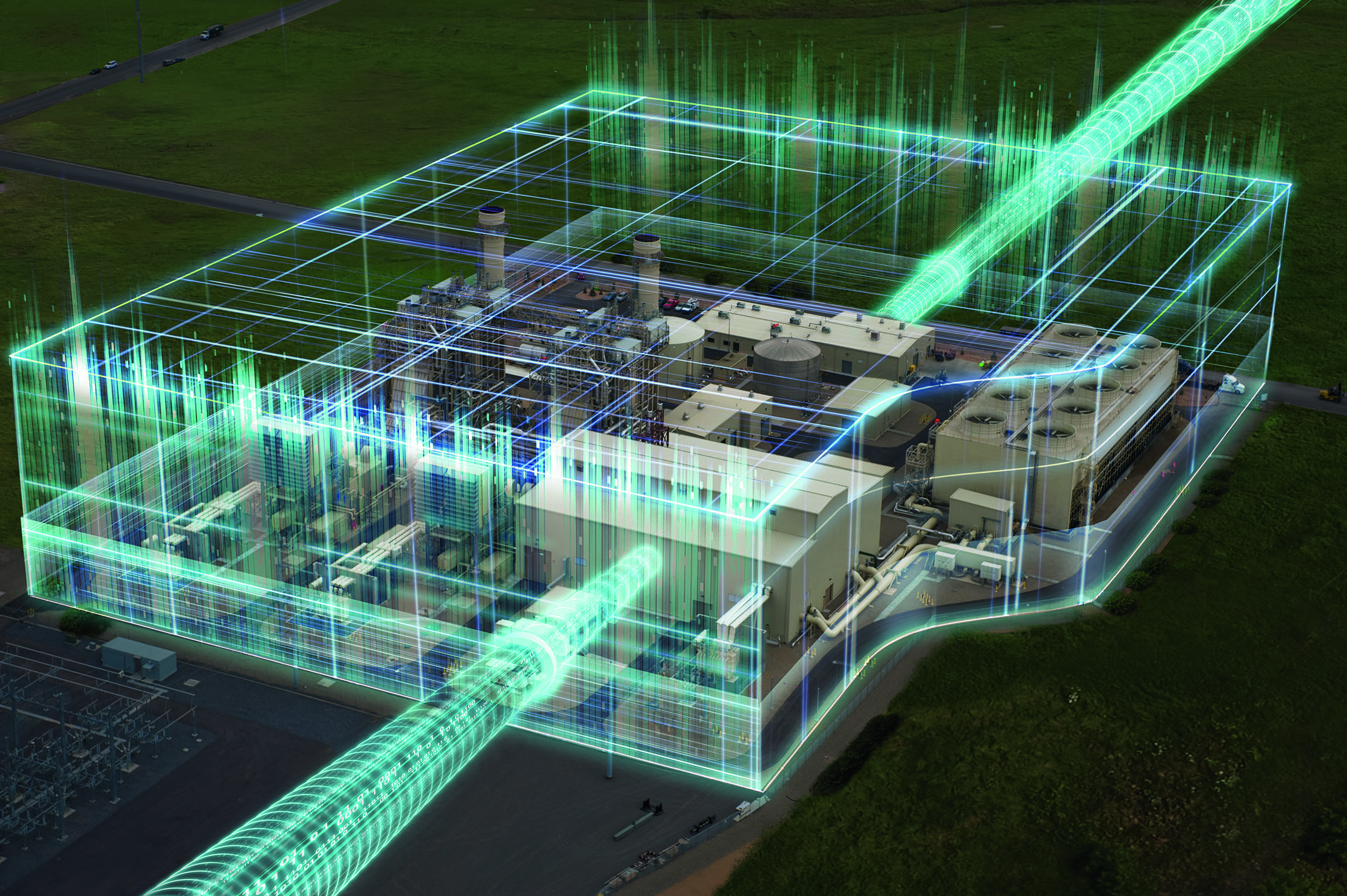

But did you know digital twins can now be deployed at the operational level? Our new on-demand webinar showcases how simulation insights can directly support your operations using executable digital twins. With breakthroughs in cloud computing, machine learning and artificial intelligence, engineers can react in near real-time to production issues by applying insights gained with process simulation.

Use simulation insights to your businesses’ advantage

Processes are complex in the energy and chemical industry. By using simulation, engineers better understand process complexity while gaining new opportunities to deploy the insights to your businesses’ advantage. Physics-based simulation models, at varied length scales, allow engineers to capture this complexity and use it to explore design and operating spaces to find optimum conditions.

Ready to investigate problems across all lengths and time scales?

An essential requirement for physics-based simulation is investigating problems across all lengths and time scales. Your engineering team may need a fit-for-purpose tool for a given scale. If multiple tools are required, integration must be seamless while offering an efficient workflow. Learn how to reduce your engineering costs while increasing performance by watching our webinar.