Unpacking the impact of the pandemic on electronics manufacturing and how its driving digitalization

Siemens Digital Industry Software launched “The Voice of Smart Digital Manufacturing”, a 10-part podcast series. It’s dedicated to the industry of tomorrow and the impact that smart digital manufacturing is having and what to expect from it in the future. We interviewed experts from different industries – from Medical and Industrial Machinery to Electronics – to share their experiences with digitalization and how it helped overcome their challenges. This series will shine a light on the road ahead for industries that are willing to embrace change brought on by digital transformation.

In the first episode of the podcast series, we talked with Dr. Raffaello Lepratti about smart digital manufacturing and how Siemens enables industry manufacturers to become leaders. In the second episode, we shifted to leveraging digital infrastructure to accelerate growth in the medical device and diagnostic industry.

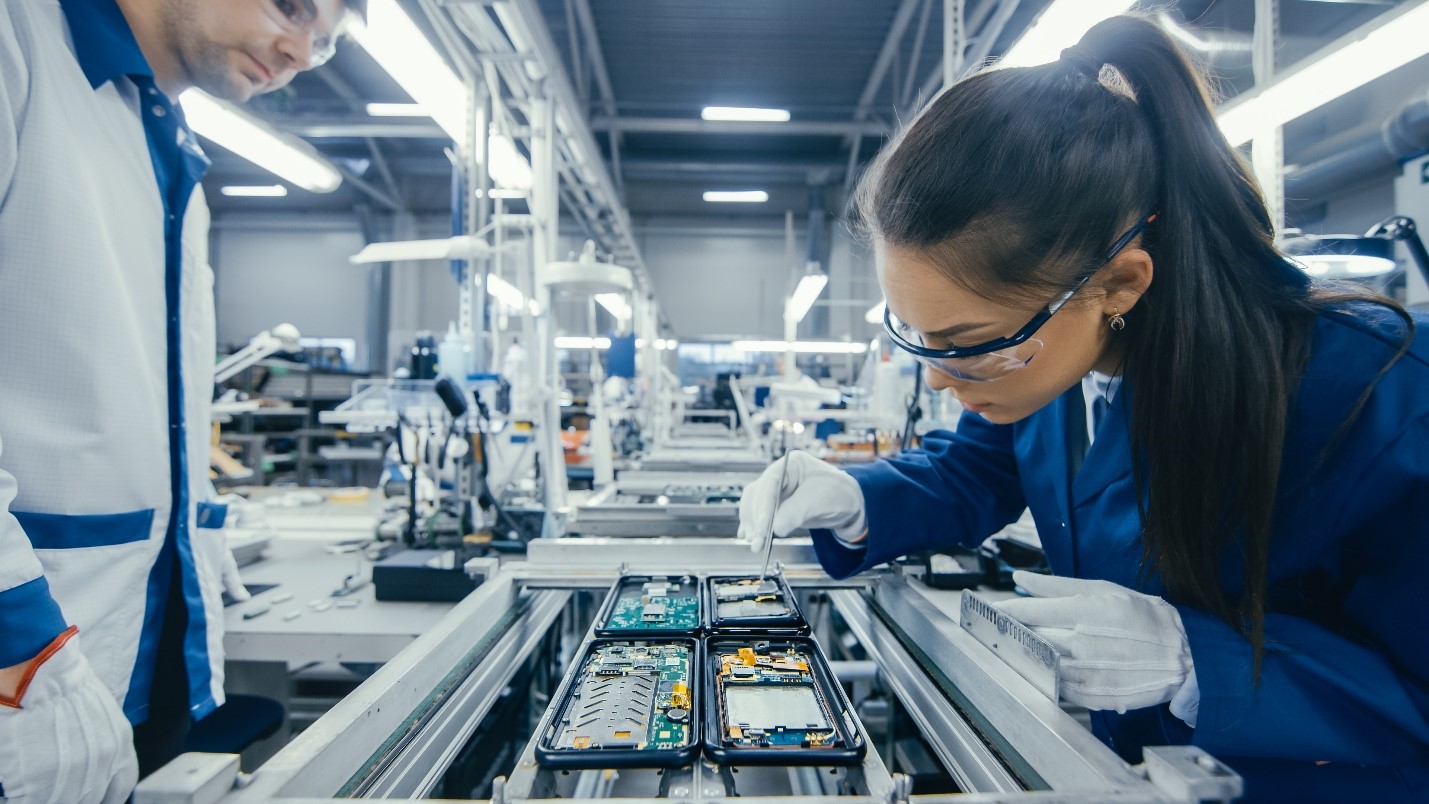

In our third episode, we’re discussing the impact COVID-19 had on the electronics industry. We talk about manufacturing disruptions from lockdowns to increased supply chain disturbances. Let’s learn how digitalization is working to alleviate these impacts on electronics manufacturing.

Meet the expert

First, let’s meet our industry expert for this episode – Oren Manor.

Oren is the Director of Business Development for Digital Manufacturing at Siemens Digital Industries Software. He is responsible for charting the future direction of Siemens’ products and technologies for the electronics manufacturing portfolio. Oren has been working in this role for almost a decade, coming from the Valor division of the Mentor Graphics acquisition. Prior to working at Siemens, he worked for Signature-IT and Jungo in business development and sales positioning.

Oren received a Bachelor of Science in Computer Science and Economics from Tel Aviv University.

Connect with Oren Manor on LinkedIn.

The impact of COVID-19 on electronics manufacturing

Before the pandemic, many electronics manufacturers talked about digitalization for years, but hesitation prevented adoption. When COVID-19 hit, suddenly all the talk about digitalization became a real necessity. Social distancing, manufacturing flexibility and supply chain disruptions drove the massive impact on the electronics industry.

Firstly, social distancing continues to play a big role in the approach to managing the pandemic. Activities that aren’t critical to the in-person production line such as pre-production, engineering, bill of material development, and machine recipes preparation can be done far away from the machines. Manufacturers needed a better digital infrastructure to help companies develop new products without physically being on the production line.

Secondly, electronics manufacturers needed much more flexibility on where they manufacture their products and how decreasing batch sizes are impacting production. Lockdowns impacted when some manufacturers ran production, leaving them to chase available manufacturing capacity across the globe. Since production lines are not identical from site to site, moving them is not trivial and many waited to continue production after lockdowns ended. To seamlessly change over from one site to another, manufacturers need digital twins, machinery and software to set up to make it work.

Thirdly, the global shortage of electronics components driven by the supply chain disruptions impacted electronics manufacturers. The primary costs for many electronics products are the components. With the pandemic, some components aren’t available for months (or years), resulting in changes in the design to be able to manufacture. With every change comes revisions and new product introduction tests, and more challenges for the manufacturer. To counteract these issues, manufacturers can better track material usage, optimize the way they are used and avoid excess on-hand inventory.

Listen to the podcast today

Learn how digitalization is impacting the electronics manufacturing industry. Listen to the latest episode of “The Voice of Smart Digital Manufacturing” podcast here.