From fragmented to connected: Rethinking the electronics design journey

How digital design threads connect concept, design, and manufacturing to reduce risk, rework, and time to market

After weeks of careful component selection and circuit optimization, your electrical engineering team finalized the schematics. They hand it off to the PCB layout team, who places some critical edge connectors for the mechanical team to review. Meanwhile, the mechanical team is working with a different CAD model without realizing it. You get to manufacturing weeks later and are met with assembly issues that could have been caught weeks earlier. Sound familiar?

Unfortunately, this frustrating and expensive process is common for teams of all sizes. When design data fragments across teams, tools, and development phases, the consequences cascade: missed requirements force late-stage redesigns, manual data re-entry introduces errors, manufacturing surprises delay production launches, and compressed rework cycles put impossible pressure on already-stretched teams.

But what if it didn’t have to be this way? What if your entire design journey – from initial concept to final production – was seamlessly connected, with every decision, requirement, and constraint flowing intelligently through each phase?

The answer lies in digital design threads: the connective tissue that transforms fragmented processes into integrated, intelligent design workflows.

Connecting design intent to manufacturing reality

Today’s electronics designs are more complex than ever. Electrical, mechanical, and software domains converge in increasingly sophisticated systems from autonomous vehicles to medical devices to 5G infrastructure. As more domains interact, design teams face exponentially more handoffs, reviews, and coordination points. This complexity creates a significant management burden: team leaders must continually orchestrate both design intent and project context across fragmented, disconnected workflows—often without automated support or unified visibility. The result is more time spent managing alignment and less time focusing on technical innovation and strategic oversight.

The hidden costs of these data silos are staggering

Most current workflows didn’t start with cross-domain complexity in mind; they evolved organically, step by step, as toolchains and teams grew. This means many organizations now rely on legacy point solutions: specialized tools excelling at individual tasks, but failing to communicate, integrate, or scale efficiently.

Planning and predictability risks

Disconnected data flows undermine project scheduling and resource commitments. Forecasting accurate timelines or budgets becomes guesswork when information is fragmented.

Manual handoffs create friction and errors

Every time design data moves from one tool or team to another, information gets lost, misinterpreted, or manually re-entered. Each handoff is a risk factor in multiplying downstream mistakes. These manual processes are a hidden drain on senior engineers, pulling technical leaders into low-value coordination and reconciliation work, rather than oversight and innovation.

Design context disappears

When the “why” behind design decisions isn’t captured and preserved, teams lose critical rationale. Why was this component selected? What constraint drove this layout decision? Without context, future modifications become guesswork.

Manufacturing surprises often strike late

Manufacturability checks commonly happen at the end of the process – if they happen at all. Design for Manufacturability (DFM) without early, continuous validation reveal costly issues when it’s most expensive to fix them. Board spacing violations, assembly conflicts, and fabrication constraints surface only after significant investment.

Rework cycles compress timelines

Each iteration to fix disconnected data, resolve conflicts, or address late-stage manufacturing feedback eats into already-tight schedules. Teams rush to meet deadlines, quality suffers, and innovation takes a back seat to firefighting.

Legacy workflows weren’t built for today’s multi-domain complexity

Legacy workflows weren’t designed for today’s multi-domain complexity or the accelerated pace of modern product development. Most organizations rely on isolated tools and organically evolved processes that inevitably create disconnected workflows that pose persistent risk and hidden inefficiencies.

To keep pace, engineering teams need electronic design environments that are scalable by design, not accident; platforms that capture and preserve design rationale, eliminate data silos, and connect every stakeholder throughout the entire lifecycle. The future demands collaboration and continuity by design, from concept through manufacturing and beyond.

Design threads connect concept to reality

Enter digital design threads: persistent, intelligent data flows that carry design intent, requirements, and decisions through every phase of development. These digital threads support how teams actually work, rather than imposing new process layers. Think of them as the nervous system of your design process, providing real-time, context-rich information for continuous verification exactly where and when it’s needed.

The true power of digital threads is their ability to dramatically reduce the need for managers and technical leads to serve as the “human glue” holding projects together. With critical data automatically connected and shared across domains, teams spend less time on manual alignment and more time innovating.

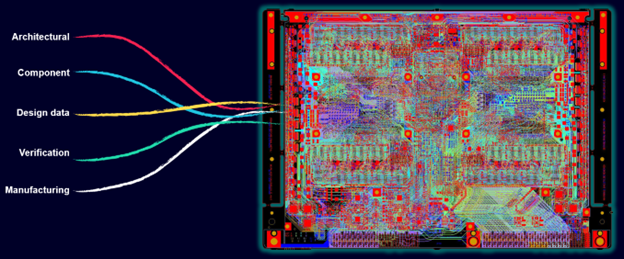

Five digital threads form the building blocks of integrated design

The core principle is simple yet transformative: one source of truth, continuously accessible and validated. Instead of data living in isolated silos, information flows seamlessly bridging domains, uniting teams, and connecting every stage of the lifecycle from concept to manufacturing. Best of all, this integrated design flow scales as teams grow from informal coordination to structured collaboration.

1. Architecture thread: capture the “why”

The architecture thread preserves design decisions and rationale from concept through production. It answers: Why did we choose this approach? What requirements drove this architecture? What trade-offs did we consider? This thread ensures that design intent and the strategic thinking behind your product never gets lost.

2. Component thread: optimize with intelligence

The component thread brings supply chain intelligence, compliance data, and reuse opportunities directly into the design process. It ensures consistent, optimized component usage across designs while flagging lifecycle risks, availability issues, and cost implications in real-time.

3. Design data thread: synchronize domains

The design data thread maintains consistency as designs evolve across electrical, mechanical, and software domains. It synchronizes board outlines, connector placements, mounting holes, and thermal considerations ensuring electrical and mechanical teams always work from the same truth.

4. Verification thread: validate continuously

The verification thread implements validation throughout the design process, not just at the end. It continuously checks designs against requirements, constraints, and manufacturing rules to proactively catch errors when they’re easiest and cheapest to fix.

5. Manufacturing thread: embed production intelligence

The manufacturing thread brings fabrication and assembly intelligence directly into the design environment. It ensures designs are optimized for production from day one, with DFM/DFA analysis, supplier requirements, and manufacturing constraints guiding decisions at every step.

These five threads don’t operate in isolation; they interweave throughout the entire lifecycle, creating a comprehensive digital fabric that connects concept to reality.

How digital threads flow end-to-end

Let’s walk through how digital threads transform the design journey:

Concept & architecture phase:

Your team defines design intent and captures it in the architecture thread. Requirements, constraints, and strategic decisions are documented and linked to design elements creating a foundation that persists throughout development.

Schematic & design capture:

The component thread activates. Intelligent libraries provide real-time supply chain insights, lifecycle data, and compliance information. Engineers select parts with confidence, knowing they’re making informed decisions backed by current market intelligence.

Design verification:

The verification thread continuously validates your design against requirements and constraints. Electrical rule checks, signal integrity analysis, and constraint verification happen in real-time during the design process and not as afterthoughts. Issues surface immediately, when they’re easiest to address.

PCB layout:

The design data thread ensures electrical-mechanical synchronization. Board outlines, component placements, and mechanical constraints flow seamlessly between domains. Meanwhile, the manufacturing thread previews DFM issues, flagging potential fabrication and assembly problems before layout is complete.

Collaboration & review:

Cloud-enabled real-time sharing, markup tools, and feedback loops accelerate decision-making. Stakeholders across departments and geographies review designs, add comments, and resolve issues collaboratively all working from the same source of truth with intuitive design context, reducing review churn and decision fatigue.

Manufacturing & production:

ODB++ outputs, comprehensive DFM/DFA analysis, and supply chain orchestration come together. Manufacturing partners receive complete, validated data packages. Issues are resolved proactively, not reactively, leading to fewer surprise escalations late in the program.

The key insight? No handoffs, no re-entry and no lost context. Your team works with ONE continuous digital fabric from concept to production.

Integrate digital threads, deliver quality results

The benefits of integrated digital threads extend far beyond workflow efficiency:

Data continuity:

Eliminate rework caused by scattered information. Design context, requirements, and decisions are preserved at every touchpoint. Teams spend time innovating, not reconstructing lost knowledge and manually transferring data.

Accelerated time-to-market:

Automated handoffs, integrated verification, and design reuse compress development cycles transforming what used to take weeks into days; they also enhance schedule reliability. With streamlined processes and fewer manual interventions, teams consistently meet key milestones and delivery dates. As a result, products not only reach the market faster, capturing critical competitive advantage, but also do so with predictable, dependable timelines that stakeholders can count on.

Quality & reliability:

Early, continuous validation catches errors before they reach manufacturing. Fewer prototype spins, higher first-pass success rates, and more reliable products result from proactive verification.

Cost reduction:

Fewer design iterations, better manufacturing yield, and faster production decisions directly impact the bottom line. Late-stage, expensive engineering changes become rare exceptions rather than routine occurrences.

Resilience & sustainability:

Built-in supply chain intelligence and manufacturability analysis empower engineering teams to create resilient designs right from the start. Component obsolescence risks are identified early, while alternative parts can be evaluated proactively to maintain momentum even in the face of unexpected supply disruptions. Sustainable material choices and responsible manufacturing processes are considered from day one, supporting environmental targets and compliance.

This resilient approach is fundamental to effective risk management. By continuously monitoring supply chain dynamics and manufacturability throughout the design process, teams can anticipate potential issues before they escalate to proactively mitigate risks to project timelines, costs, and product quality. The result is robust, sustainable products that are not only innovative, but also prepared to withstand real-world challenges.

Team and workflow agility:

Seamless collaboration across departments, geographies, and skill levels transforms how teams work. Remote engineers contribute as effectively as on-site staff. Cross-functional teams align naturally around shared data and common goals.

The Siemens approach: integrated data, scalable solutions

Siemens stands apart in digital thread integration, bringing unmatched multi-domain expertise across electrical, mechanical, PLM, and software domains. Our comprehensive digital twin capabilities bridge the virtual and physical worlds, enabling insight and optimization at every stage. Crucially, Siemens offers solutions that are proven to scale from empowering individual engineers to orchestrating electronic system design across global enterprises.

Our approach is designed for both today’s challenges and tomorrow’s ambitions, enabling teams to excel in daily execution while building toward long-term process maturity.

Xpedition technology embodies these strengths:

- Unified user experience across all product tiers from PADS Pro Essentials to Xpedition Standard to Xpedition Enterprise. Teams learn once and scale seamlessly as needs grow.

- Shared data foundation ensures ONE design, ONE source of truth. Whether you’re working solo or coordinating global teams, everyone accesses the same validated information.

- Cloud-enabled or local collaboration and supply chain intelligence break down geographical and organizational barriers. Real-time sharing, markup, and review tools keep distributed teams synchronized.

- AI-driven automation reduces manual tasks, letting engineers focus on innovation rather than repetitive processes. Command prediction, intelligent part selection, and automated routing accelerate productivity without sacrificing control.

PCB design solutions that scale with your organization without disrupting how you work

With Siemens Xpedition, scaling your PCB design capability never means starting over or rethinking the workflows your teams already trust. The Xpedition product family delivers growth on your terms empowering individuals, advancing teams, and supporting global enterprises with seamless continuity and integration at every stage.

Key enablers include:

- Integrated libraries that ensure data and process consistency from design to manufacturing.

- PartQuest Portal for instant access to real-time supply chain intelligence, minimizing procurement risks and delays.

- PCBflow for comprehensive automatic DFM/DFA analysis, guaranteeing manufacturability and resilience from the outset.

- Robust remote collaboration tools so teams stay connected and productive, regardless of geography.

Solutions that adapt to every stage of growth

- PADS Pro Essentials delivers digital threads for individual designers. Professional-grade tools at entry-level pricing provide the foundation for growth.

- Xpedition Standard enables cross-functional team workflows with enhanced integration. As teams expand, capabilities scale without forcing users to learn new tools or translate data.

- Xpedition Enterprise provides full electronic system orchestration, governance, and strategic decision-making capabilities. Global enterprises gain comprehensive control while maintaining agility.

Why digital threads create competitive advantage

The market reality is unforgiving: innovation cycles are accelerating, designs are growing more complex, teams are increasingly distributed, and supply chain volatility is the new normal. In this environment, digital threads aren’t a nice-to-have; they’re essential for survival and growth. Digital threads are essential because they enable teams to manage growing complexity without the burden of increased management overhead.

Early adopters gain measurable competitive advantages in speed, quality, and cost. They bring products to market faster, with higher reliability and lower development costs. They respond to supply chain disruptions proactively rather than reactively. They attract and retain top engineering talent by providing modern, efficient tools.

Digital threads also future-proof your organization. Platforms built on digital thread principles scale naturally with emerging technologies, such as AI-driven design automation, autonomous systems requiring unprecedented reliability, 5G infrastructure demanding new levels of integration. As technology evolves, integrated platforms evolve with it.

From fragmented to seamless: Ready to transform your design process?

We’ve traced the journey from isolated tools and manual handoffs to integrated, intelligent digital workflows. From design data scattered across disconnected systems to persistent threads that carry intent, requirements, and decisions seamlessly from concept to production.

The vision is clear: design teams that move at the speed of innovation, with confidence and clarity. Teams that spend time creating breakthrough products, not reconstructing lost information or firefighting preventable problems. Your next breakthrough product starts with seamless, connected design workflow powered by Xpedition technology. The future of electronics design is integrated, intelligent, and seamless. Explore the Siemens Xpedition Product Family.