Advantages of KSK in auto manufacturing

Modern passenger, recreational and commercial vehicles are built with an abundance of electronic features and components for safety and comfort. These range from air-conditioning, in-vehicle infotainment (IVI) systems and automated features to electronic control units (ECUs) that manage braking, steering and throttle control. Further, the onset of higher levels of autonomous driving, advanced driver assistance systems (ADAS) and electromobility increases the complexity of wire harness manufacturing.

The KSK concept (Kundenspezifischer Kabelbaum) originates from Germany and translates to a customer-specific wire harness. The surge in demand for mass customization is driving up the number of unique vehicle configurations, increasing the wiring harness’s complexity and variance now more than ever. KSK is the best solution, but change becomes difficult the more complex the design.

KSK production generates and consumes large amounts of data. This data is critical to the efficient operation of the production system. However, data alone is not enough. Harness manufacturers must be able to gather data quickly, sort and filter out essential data and analyze to derive insight into the production process.

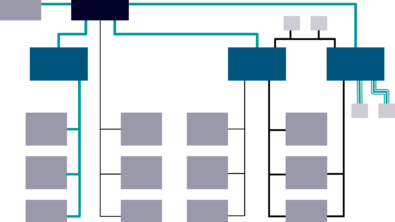

This is possible with a digital twin approach using a comprehensive E/E systems development solution for KSK. Harness manufacturers can use software like Capital from Siemens Xcelerator portfolio for tasks such as modularization, production module preparation, assembly board optimization, time calculation, line balancing, change management, standard working instructions and production reports.

Interested in seeing how Siemens can help with KSK implementation or how common issues can be tackled? Check out this KSK webinar series by our resident expert:

- Advanced harness manufacturing engineering with KSK and big data– learn more about how KSK fits in engineering, manufacturing and logistics and what big data and the IT landscape means for KSK.

- Utilize a comprehensive digital twin in KSK production – in this webinar, explore the Capital solutions for manufacturing engineering and plant simulation for virtual process optimization.

- Change management solutions for the wire harness business – in this final in the three-part series, hear about the challenges of change management and how advanced harness manufacturing engineering solutions can help.

Learn about Capital products for wiring harness design and harness manufacturing.