Siemens-imec collaboration reduces stochastic failures in EUV lithography by orders of magnitude in wafer-level experimental validation

By Azat Latypov

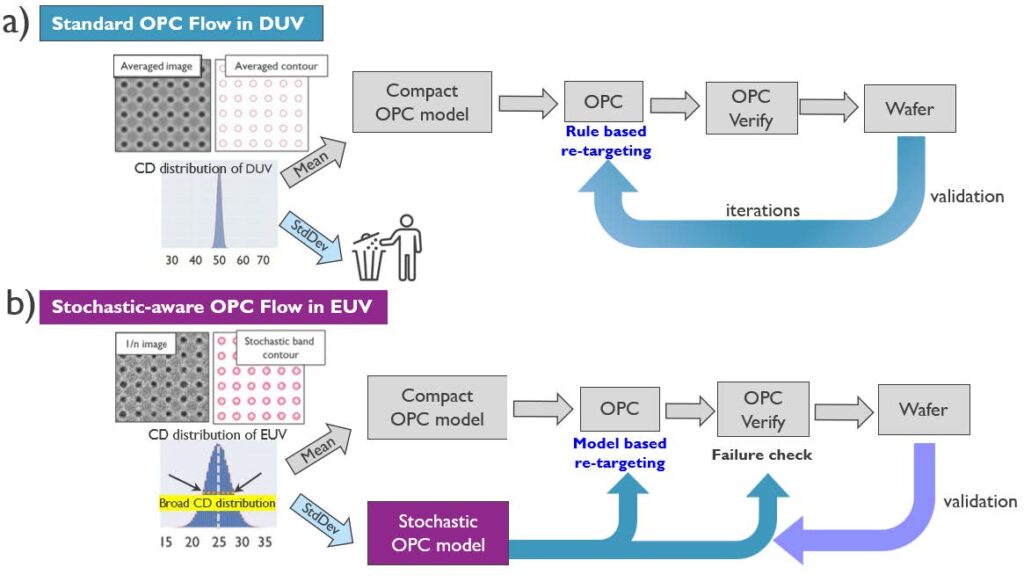

As semiconductor technology pushes deeper into advanced nodes, extreme ultraviolet (EUV) lithography introduces new challenges in both process control and design optimization. Traditionally, optical proximity correction (OPC) has relied on deterministic compact models that focus on “average” behavior—assuming that systematic process control, with accurate CD prediction, is enough to ensure yield. But with the stochastic nature of EUV photon-driven imaging, this approach leaves critical gaps.

For over five years, Siemens Digital Industries Software and imec have partnered to bring a new generation of OPC solutions to the production floor by embedding stochastic effects—once regarded as random “noise”—directly into the modeling and correction process.

The recent 2025 PMJ paper by our imec colleagues presents the convincing experimental validation of one stochastic-aware Calibre OPC strategy using wafer-level CDSEM data across various lithographic conditions, demonstrating at least one to two orders of magnitude improvement in stochastic failure probabilities, as predicted earlier in simulations using Calibre stochastic model in the joint imec-Siemens 2023 SPIE paper.

We review below how this collaborative journey was progressing and how it is making manufacturing more robust.

Building a foundation: Establishing and calibrating a physically accurate stochastic model

The Siemens-imec collaboration did not begin with theory, but with rigorous experimental validation. As early as 2020, imec worked with Siemens to test the first generation of the Calibre Gaussian Random Field stochastic models against experimental wafer data.

The application of properly calibrated Gaussian Random Field models to the simulation of stochastic deprotection fields in EUV optical and resist processes ensures capturing both the effects of local randomness and the effects of spatial correlations. Similarly to the classic level-set methods, the use of random deprotection fields facilitates stochastic simulation and mitigation of lithographic defects (disappearance or merging of lithographic features, bound by the level-sets corresponding to certain thresholds).

Using advanced metrology developed by imec’s Peter de Bisschop, metrics like pixNOK (pixels “Not OK”) and Number_MicroBridges (the number of microbridging defects) were experimentally measured and directly compared to model predictions. Unlike the more traditional stochastic variability metrics (like LER, LWR or LCDU), quantifying the magnitude of small-scale deviations from the mean, the pixNOK and Number_MicroBridges stochastic metrics are introduced to quantify the likelihood of yield-affecting failures resulting from a substantial deviation from the mean (e.g. pinching/bridging of lines/spaces).

Together, these efforts led to the joint SPIE 2020 publication, which demonstrated that the Calibre Gaussian Random Field stochastic model can reliably predict these key stochastics-driven metrics measured in the lab. This verification was a critical milestone, showing strong agreement between experimental observations—such as the frequency of microbridges or “bad” pixels along the trench centerline—and the predictions of the calibrated Calibre stochastic model. In 2022, Siemens and imec researchers co-published a related study: Calibration of Gaussian random-field stochastic EUV models.

Beyond proxies: Predicting true failure probabilities and improving yield

While early stochastic metrics like pixNOK and Number_MicroBridges offered valuable, easily measurable indicators of failure-causing stochastic variability, they served as proxies for the more fundamental question: what is the true probability of patterning failure and how does it impact process yield?

In 2023, Siemens and imec published Compact modeling of stochastics and application in OPC, which applied the stochastic models to a stochastic-aware OPC flow. The latest results from the Siemens-imec partnership, published at 2025 SPIE Photomask Japan by imec researchers, mark a significant step forward. This study directly compares the predicted and observed failure probabilities themselves—quantities that directly impact litho yield and reliability, and are directly actionable for OPC optimization. This moves beyond using proxy metrics to establish a closer, production-relevant link between modeling and manufacturing outcomes.

How compact stochastic models capture variability in EUV

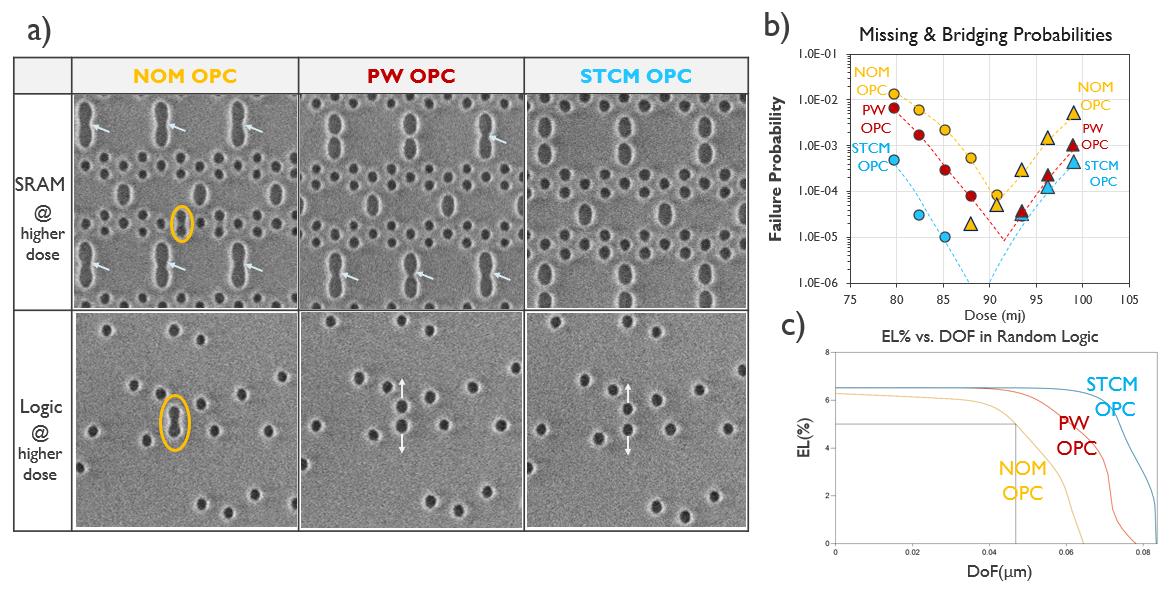

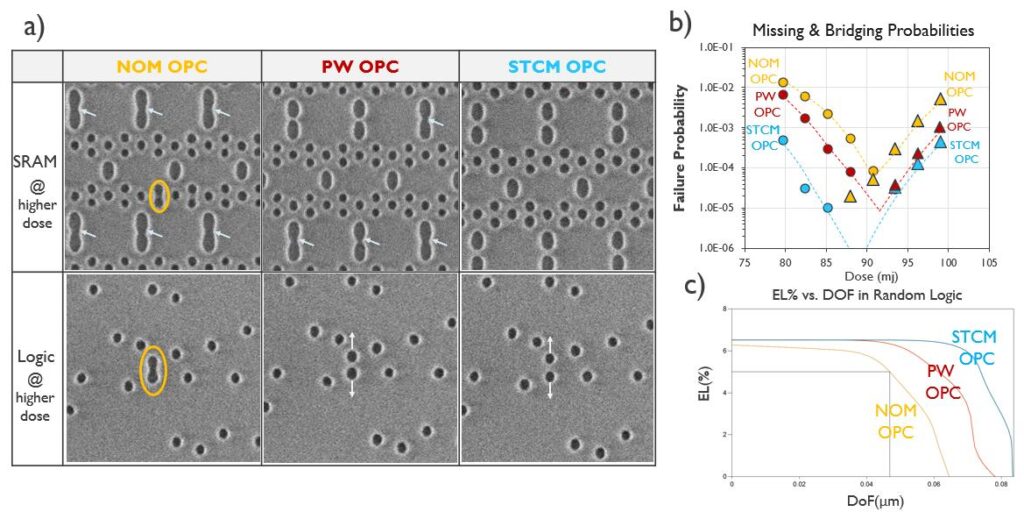

In the published studies, compact stochastic resist models were calibrated using both nominal and process-window wafer data. The Calibre platform’s compact stochastic models accurately predicted wafer-level CD uniformity (LCDU) and variability across a range of layout patterns, pitches and processing conditions—demonstrating fitting errors well under 1 nm, both in nominal and off-nominal conditions. Figure 1 illustrates the standard and stochastic-aware flows.

From measurement to correction: Embedding stochastics in OPC

The most recent joint work (Compact modeling of stochastics and application in OPC), took the next leap: directly embedding stochastic modeling into the OPC process, not just for analysis, but to actively reduce random manufacturing failures.

We compared three approaches:

• Nominal OPC: Traditional correction, focused on average CD placement

• Process window OPC (PW-OPC): Incorporates systematic process variation bands (focus, dose, etc.)

• Stochastic-aware OPC (ST-OPC)**: Incorporates the full stochastic band, as modeled and calibrated, into the OPC cost function

Incorporating stochastic-aware OPC led to at least an order-of-magnitude reduction in the probability of stochastic defects for both SRAM and logic designs. The method systematically sacrificed minor edge placement error (EPE) in return for much lower failure rates, optimizing for robust yield in the random, photon-limited world of EUV. Figure 2 shows results of these experiments.

A key insight: when the stochastic and process variation band widths are matched—such as in layouts with very narrow CD ranges—the resulting OPC solutions converge. But in realistic, feature-rich layouts, stochastic-aware OPC provides fundamentally new, yield-relevant optimization.

A collaborative legacy, a production-ready future

This journey—spanning experimental metrology, model development and joint validation—shows how deep research partnerships can deliver actionable production value. With Siemens-Calibre’s modeling platform and imec’s world-class lithography R&D, the industry now has a path to both understand and mitigate real stochastic risk, not just proxies or averages.

Looking ahead, Siemens and imec are extending stochastic-aware OPC to more complex process chains and developing robust, automated workflows to bring these advancements to every design and manufacturing team.

As illustrated by the list of references and related resources in the Siemens recent paper, Compact modeling of stochastics and application in OPC, Siemens EDA continues advancing the fundamental EUVL stochastic research and development effort. One direction of this effort covers the accurate compact stochastic models capable of computationally efficient prediction of lithographically meaningful metrics of stochastic variability. This direction covers importance sampling strategies, principal components and feature vectors of stochastic variability as well as incorporating chemical stochastics and mask writing e-beam process stochastics models. Another direction of the stochastic R&D effort covers the stochastic-aware OPC mitigation strategies, as detailed above.

If you want to learn how stochastic-aware OPC and the Siemens-imec collaboration are enabling the next leap in EUV yield and manufacturability, we’d love to discuss or demonstrate these latest advances.

For further reading:

Compact modeling of stochastics and application in OPC (2023), Siemens Digital Industries Software.

Stochastic-aware compact OPC model validation for reducing failure probability, 2025 SPIE Photomask Japan

Probability prediction of EUV process failure due to resist-exposure stochastic: applications of Gaussian random fields excursions and Rice’s formula, 2020 SPIE Advanced Lithography

Calibration of Gaussian random-field stochastic EUV models (2022), Siemens Digital Industries Software.