Predictive precision: Aligning detailed engineering with integrated architecture

Innovation no longer moves in a straight line.

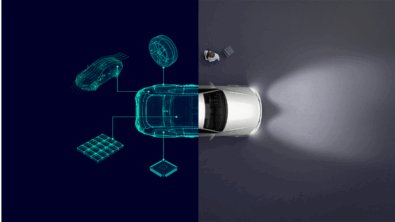

Vehicles today are not mechanical machines alone; they are highly complex systems where software, electronics and mechanical components intersect in ways we couldn’t have imagined even a decade ago. This convergence has unlocked incredible innovation, from electrification and connectivity to autonomous functions — but it has also exposed cracks in the traditional development process.

For too long, engineering teams have worked in parallel but disconnected tracks. Mechanical engineers, electrical system designers and software developers have each advanced in their own domains, often using different tools, languages and workflows. This separation worked in a simpler era, but in today’s world of software-defined vehicles, integrated E/E architectures and constant connectivity, it’s a liability.

The need now is clear: align detailed engineering across disciplines within an integrated architecture. Without this alignment, manufacturers will struggle to deliver the innovation, quality, and speed the market demands.

Why the old approach falls short

Today’s automotive systems are interdependent. A change in the electrical architecture can affect mechanical packaging; a new software function may increase thermal load or power demand; an update to the mechanical design can ripple through the entire E/E system. Yet many companies still operate in silos, with teams handing off work across rigid phase gates, relying on late-stage integration to resolve mismatches. This leads to rework, delays and missed opportunities to optimize across domains.

A new model for modern engineering

Alignment starts by breaking down those silos, not just organizationally but technologically. It means embedding mechanical, electrical and software engineering into a shared environment where architectures, requirements and dependencies are visible and connected from the earliest stages. This is where model-based systems engineering (MBSE) comes into play.

With MBSE, design choices are validated not in isolation, but as part of a system. Software engineers can test control strategies against real mechanical constraints; mechanical teams can model the thermal impact of new software features; electrical designers can explore trade-offs between cost, weight and performance in the context of the full system.

This is not hypothetical. Siemens’ solutions, including Teamcenter and Capital, are already making this kind of cross-domain collaboration possible. Customers are moving away from document-based processes to integrated digital threads that connect requirements, designs and validations across disciplines — creating a single source of truth that accelerates development and improves quality.

The power of integrated domains

Mechanical product engineering benefits by embedding mechanical design into a connected workflow, enabling engineers to explore innovative geometries and materials without losing sight of how they’ll interact with electronics and software. Electrical engineering, through tools like Capital, gains the ability to manage increasingly sophisticated E/E architectures with full traceability — crucial for safety, compliance and serviceability. Software engineering is transformed by linking embedded development directly to physical systems, allowing teams to deploy, update and validate functionality at unprecedented speed.

When these domains come together, something powerful happens. Companies gain the ability to manage complexity rather than be overwhelmed by it. They can optimize across the full system, rather than sub-optimizing in isolated pockets. And they can deliver vehicles that are not only cutting-edge at launch but able to evolve over time through software updates, extending their value in the market.

Lessons from the leaders

One global automotive supplier, DENSO, has embraced this integrated approach with impressive results. By shifting toward model-based, cross-domain development, DENSO has reduced design errors, improved first-pass yield and accelerated its time to market. The company’s success underscores a broader truth: the future belongs to those who can work across boundaries, not just within them.

Looking ahead

The alignment of detailed engineering with integrated architecture is what enables the next generation of mobility — from safer, cleaner vehicles to more sustainable, efficient manufacturing. For companies that master it, the reward is not just better products, but a more resilient, adaptive organization ready for whatever comes next.

Discover more about how Siemens is helping manufacturers bridge the gap between architecture and engineering.