Simcenter SCADAS RS delivers unmatched standalone but connected in-field data collection experience

While I do work with a Simcenter SCADAS RS almost everyday, it’s been a while since I had to carry out a complete test campaign on proving ground. Such a task is always very challenging as many things can go wrong, and the time pressure is very high. We had to focus on multiple aspects of the vehicle, testing two different vehicles for different attributes, one for durability and one for acoustics.

As I knew from my past experience, the time on a test track goes very fast. Between checking the instrumentation, going through the list of maneuvers to do, monitoring test parameters and validating that the measurement data we collect is complete with no failures, days are packed and intense, and you never really have the feeling or certainty that all your data is there before you get off the track. A big variety of things can go wrong including sensors, equipment, vehicle, environmental conditions… and more, which in practice means anything.

To complicate my life even further, I was asked to give subjective judgement on certain aspects of the vehicle during driving conditions. This is typically a very tedious task, as you are not really able to write anything down while driving and the subjective data ends up not being linked to the data and the processing results.

Finally, preparing the vehicle beforehand as well as having the hardware and software you need and learning how to use it takes a huge amount of time, especially if you need to test different attributes on a same test campaign. In other words, I was feeling very challenged!

However, after meeting with, Gert, my partner for this test campaign, I immediately felt relieved. Gert simply had to remind me about all the new hardware and software features of the data acquisition system we were going to use on both vehicles, i.e. Simcenter SCADAS RS. Every step of the way it was clear that this was the perfect tool for the job, and I was reassured we could successfully execute the test campaign. Let my show you how.

Flexible hardware and software solution for multiple applications

First of all, we could use the same hardware and software to collect the data, despite having to focus on completely different attributes for the two vehicles under test, namely durability and NVH. Simcenter SCADAS RS hardware has a modular architecture that allows to select the required modules, being standard B24, S24 or U12 suited for durability testing amongst others, or extended bandwidth modules like the U12-E or the newly arrived S12-E, which extend the applicability of Simcenter SCADAS RS towards, for example, NVH and Acoustics.

Both Gert and I could simply get to the storage room and assemble the two systems we needed by picking and clicking-in the required modules. If required, the hardware can also work in harsh environments being rugged with IP67 rating, resisting vibrations and a wide temperature range. Finally, the system can also be distributed in case required to improve the signal quality as well as reducing cabling complexity.

Simcenter SCADAS RS is more than just hardware

You can immediately start working with the hardware with no need to install any software. The Simcenter SCADAS RS comes with on-board software, the Simcenter SCADAS RS Recorder App, which you can be directly access with any device you prefer (PC, laptop, smartphone or tablet). Not only that, you can also do so wirelessly and with multiple devices at once!

This means that Gert and I could help each other by sharing knowledge and time to best prepare both vehicles. We were able to easily switch focus from one vehicle to the other by seamlessly accessing the Simcenter SCADAS RS Recorder App, showing each other instrumentation issues to fix while walking around the vehicles.

Usability across different application fields

When it comes to channel setup, Simcenter SCADAS RS offers two flavors:

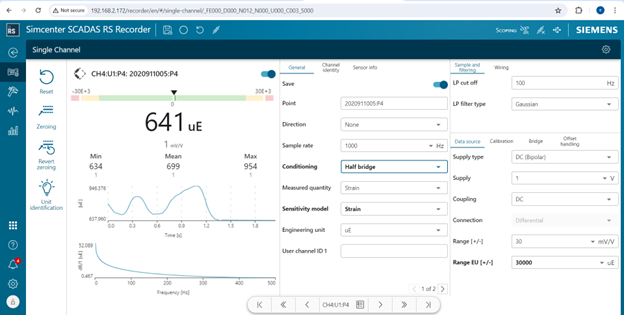

- typical channel grid view which is ideal to quickly setup typical NVH sensors like ICP microphones and accelerometers through a multiselect action or helps in getting an overview on the entire instrumentation

- the new single channel setup pane excels at giving a guided and clean focus for instrumenting more complex durability channels like strain gauges (half-bridges or full-bridges for example) one by one with contextual view on the live data.

All in all, a versatile interface for Multiphysics instrumentation!

Robust acquisition with total view and control during the test

When on the track I could focus on the drive and the maneuver execution. Useful test parameters can be monitored on the Simcenter SCADAS RS Recorder App through customizable displays while all the data is safely stored on the Simcenter SCADAS RS on board memory.

This ensures robustness in general as well as ruggedness in harsh environments.

Subjective data acquisition through the new Event Marker

Subjective data can be directly recorded through the new Event Marker app. This allows the driver to annotate and record rating on specific performance attributes or indicate any problems, such a stone hitting the windshield, directly in synch with the rest of the objective data. All is customizable in terms of the number of subjective parameters, levels, and ratings.

Focus on the road, let others worry about the task at hand

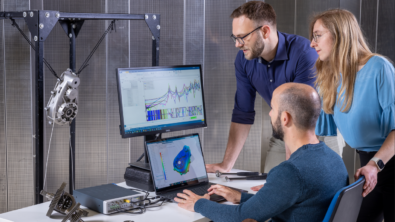

And what is really exceptional: I know that all the tests being executed as well as the entire campaign can be monitored by our requester of the campaign – Aga – who can help us validating the data and the maneuvers while we progress in the schedule, completely remotely while being comfortably sitting in her office!

This means that we can truly focus on the execution being reassured that all is progressing well. And if anything would go wrong? Well during the campaign in fact Aga noticed I was driving too fast on a few sections of the track (guilty!), and it only took a short phone call during my break to correct my execution and properly finalize the testing on time.

You can learn more about remote Simcenter SCADAS RS access in the upcoming blog of my colleague, Gert.

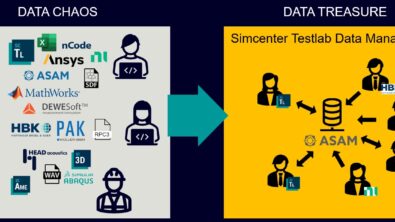

Automate data validation and processing for enhanced efficiency

And in case an on-site engineer is not available to help with the data and maneuver validation, automation can be a great alternative. Simcenter Testlab Time Workflow Automation helps to automate processing on the acquired data, from simple checks on maneuver execution to complex post-processing chains and much more. Learn a lot more about Simcenter Testlab Time Workflow Automation.

Overall, the combination of remote access to the data and processes automation minimizes the chances of discovering issues in the campaigns weeks after when back at the office, maximizing efficiency as well as optimizes usage of resources.

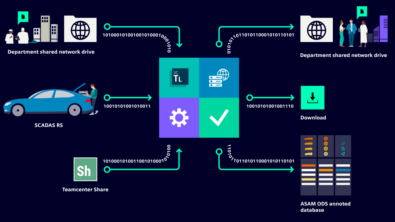

Priority on openness and connectivity

Worth also mentioning that while nowadays instrumentation sets include not only analog data, but also digital data to connect to digital sensors as well as vehicle networks to read in available data from embedded vehicle sensors, Simcenter SCADAS RS is more and more ready for that, with an improved support of CAN, J1939, XCP over CAN and XCP over Ethernet amongst others. Video can also be captured in sync with the rest of the data through multiple USB cameras directly connected to the Simcenter SCADAS RS.

Last but not least, Simcenter SCADAS RS being also a solution for NVH and Acoustics applications is ensured by additional software extensions like the introduction and support of Simcenter Testlab Neo Impact and Simcenter Testlab Neo Signature.

Time to head back

As it turned out, my initial concerns were definitely not needed. The test campaign went smoothly and by the time we came back to the office all the results were neatly processed and reports were waiting for our final signoff.

All in all, Simcenter SCADAS RS is more connected than ever, and combined Simcenter Testlab Neo and Simcenter SCADAS RS Recorder App allowed us to be versatile and efficient over different types of testing activities making our proving ground testing campaign a success. Do not hesitate to email us to have more info about any of the features described in this blog, or to check out more of the related resources below!