Cradle Support: Simplifying CNC Programming for Efficient Machining

How do I simplify CNC programming?

In the world of CNC programming, efficiency on the shop floor is paramount. Siemens has addressed this need by creating model-based CAM in Zel X, a comprehensive solution that streamlines the programming process, saving both time and material. This blog will focus on a specific use case for machining a cradle support part, showcasing the user-friendly features and capabilities for CAM in Zel X.

Zel X CAM: A Solution Tailored for Simplicity

The CNC programming landscape often involves various parts, each with its unique machining requirements. Zel X CAM was crafted with simplicity in mind, recognizing that many parts, like the cradle support we’ll discuss, demand straightforward programming methods.

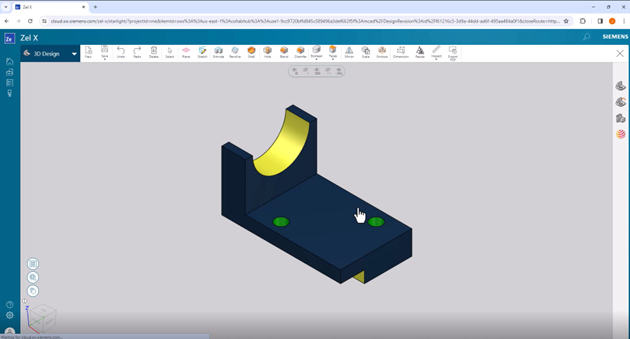

The cradle support, a weldment designed for automotive fixturing, exemplifies the efficiency of Zel X CAM. This part’s critical features, including flat mating faces, through holes, and a cradle for a cylindrical component, can be easily machined using Zel X CAM.

Step-by-step demonstration:

Programming the Cradle Support in Zel X CAM

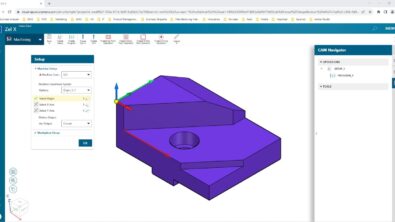

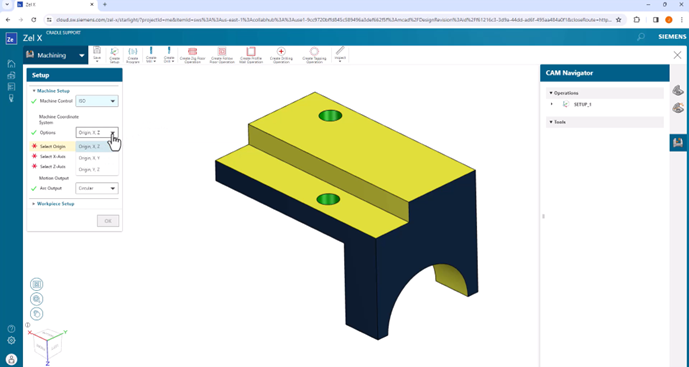

To initiate the programming process, the user enters the 3D Author environment, allowing modifications to the 3D model. Zel X’s guided workflow facilitates the setup, starting with selecting the machine tool controller and defining the machine coordinate system.

Efficient Toolpath Creation with Model-Based CAM

Explore the advantage of a model-based approach where a machinist is prompted to define setup elements, representing the machine tool and workpiece, creating a seamless guided workflow. This minimizes the learning curve, ensuring little to no training is required.

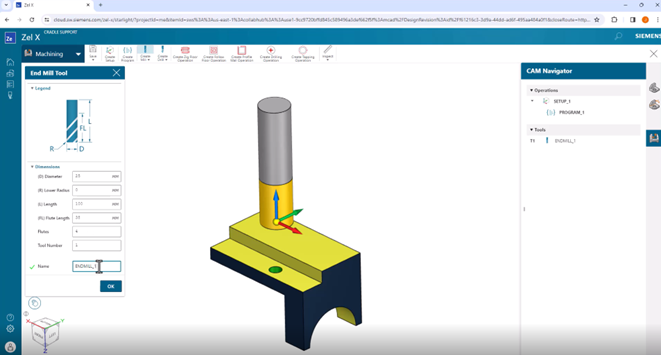

Simplified Tool Definition and Toolpath Generation

Before diving into operations, Zel X CAM requires the definition of cutting tools. The interface simplifies the process, providing only essential inputs for tool shape definition. The toolpath creation involves choosing a cutting tool and geometry, with intuitive options for cut patterns such as zigzag or rolling motions.

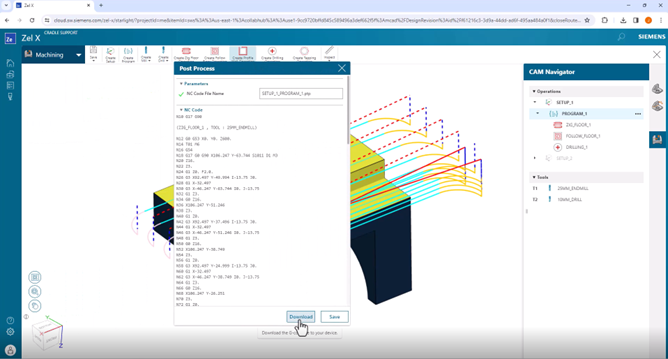

Streamlined Postprocessing and On-the-Fly Workflow

Zel X CAM doesn’t stop at toolpath creation; it seamlessly integrates postprocessing. The machinist can generate G-code instantly, eliminating the need to search for files. This on-the-fly workflow allows for quick adjustments and optimizations during machining, a common practice in job shops prioritizing efficiency.

Zel X CAM – Empowering Machinists

Zel X CAM’s model-based approach transforms CNC programming into an efficient process. Its user-friendly interface, guided workflow, and intuitive capabilities empower machinists to spend more time machining and less time programming. Whether dealing with simple or complex parts, Zel X CAM proves to be a valuable tool for enhancing productivity on the shop floor.

Everything you need, sized for your size business

Purpose built with exactly the tools you need to speed contract and part manufacturing, Zel X makes it easier to handle quotes, manage jobs and work orders, make parts, and collaborate with teams of all sizes.

The continuous release cycle of Zel X ensures delivery of those tools and functionalities as soon as possible, allowing your machine shop to move faster.

Browser-based, in an app designed with your needs in mind, Zel X helps your whole team can get started quickly so you can win more business.

Learn more about Zel X, click here.

Ready to try Zel X? Click here for a free 30-day trial.