Shop Data Management: Manufacturing Digitization

Table of Contents

The job shop evolution

There has been a push in recent years for manufacturing processes to go digital, such as moving shop floor data management to the cloud. In some sense, manufacturing started its digital transformation more than 20 years ago with the use of solid models and CAM software that was model-driven programming. However, there are still aspects of manufacturing that haven’t been digitalized, such as process planning. For years now, the manufacturing process has been created in a traditional ERP system where it prints out the traveler, which then follows each shop floor process stage from raw material to finished product. Job Shops may call these “paper job travelers,” which can cause inefficient workflows and lack of data integrity due to outdated paper-based methods.

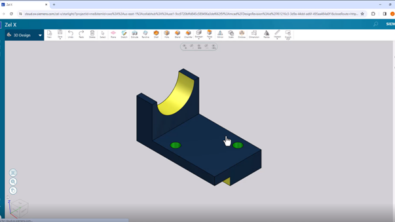

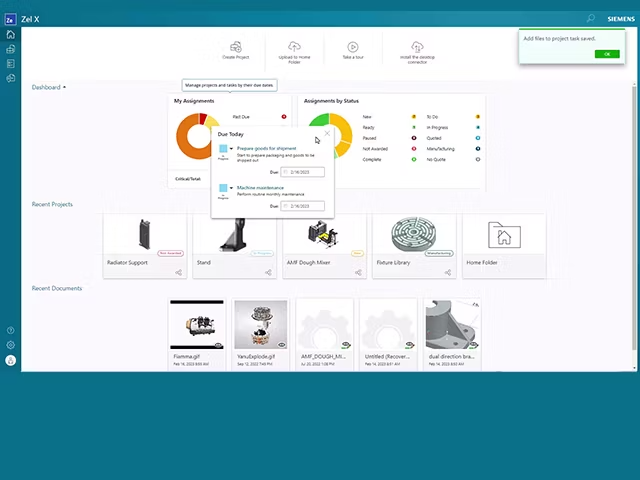

Manufacturers need to grow revenue, diversify their customer base, reduce errors, and better utilize internal resources. That’s where Siemens Zel X enters the market to provide an integrated collection of tools for collaboration, mechanical design, simulation, and manufacturing and operations. Siemens Zel X can be used as a complete solution or integrated with existing computer-aided design (CAD) and computer-aided manufacturing (CAM) tools.

About Siemens Zel X Standard

Siemens Zel X Standard is cloud-based software that speeds contract and part manufacturing processes to boost collaboration.

Zel X standard drastically streamlines how information related to the manufacturing process can be better managed from raw material to finished product. It also helps facilitate modern shop management and communication between the shop floor and the office. The web-based access provides a simple, easy-to-learn, manufacturing-centric interface backed by trusted cloud architecture.

Seamless shop floor management

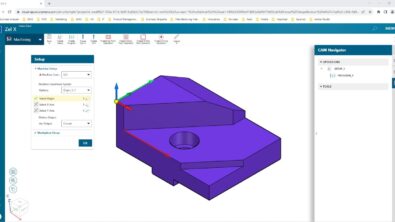

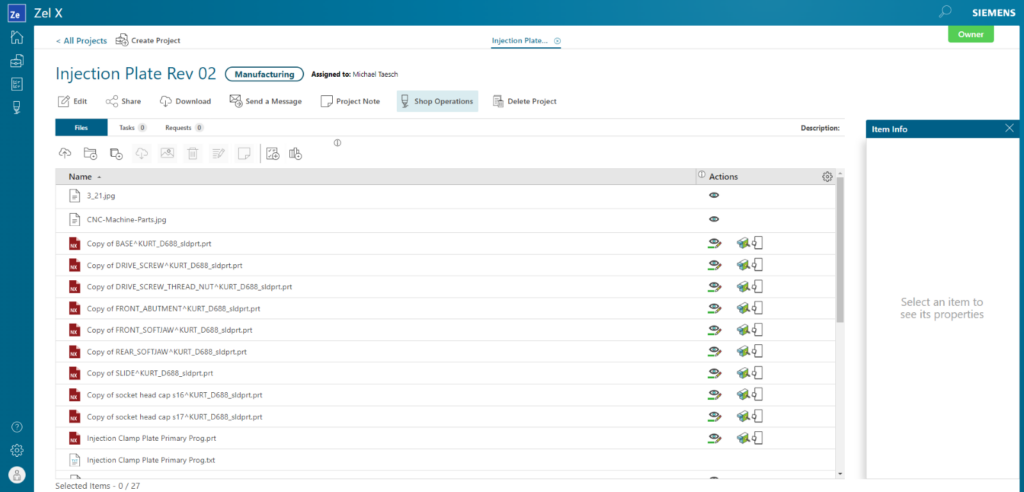

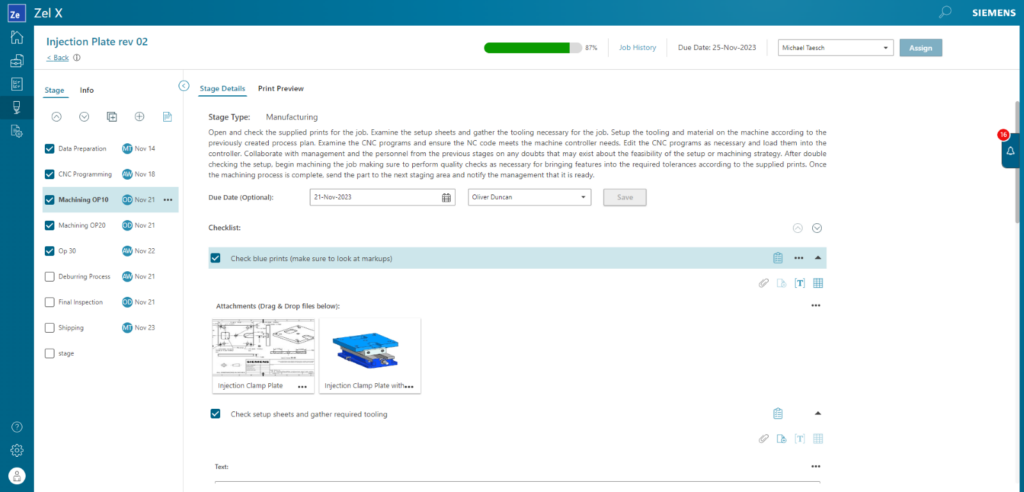

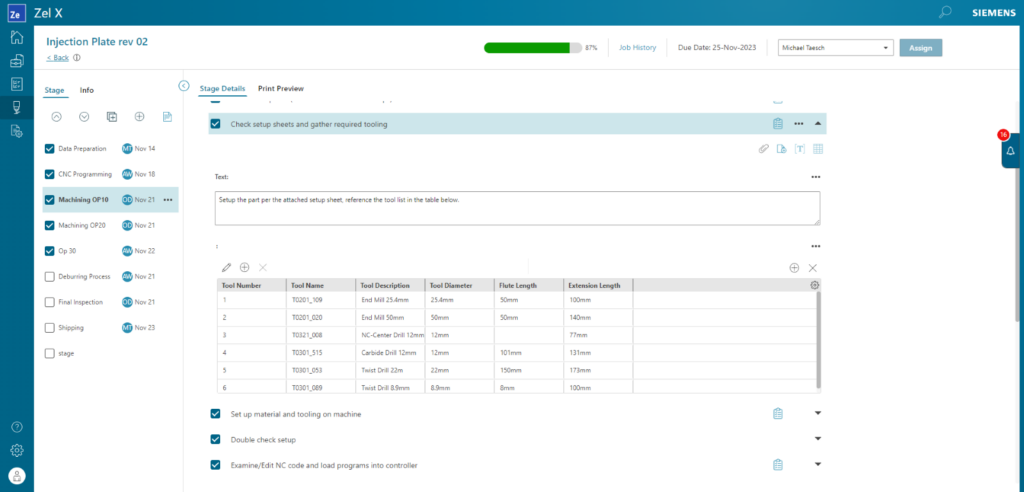

Shop Operations takes the traditional shop traveler and does more than digitize it. Allowing you to not only design the manufacturing process, but add appropriate attachments like manufacturing prints, NC programs, solid models, and images directly to the steps where the information is needed. All additional files added to any task list item while working with Shop Operations are automatically synced to the Zel X project to ensure everyone that is working on that project has access to the same data.

The addition of text boxes and tables allows you to build necessary tooling information, setup information, inspection plans, or just convey important points about any step in the process.

Collaboration is made easy through comment sections throughout the application where you can tag other users to ensure they are notified of the comment.

Cloud-based process planning

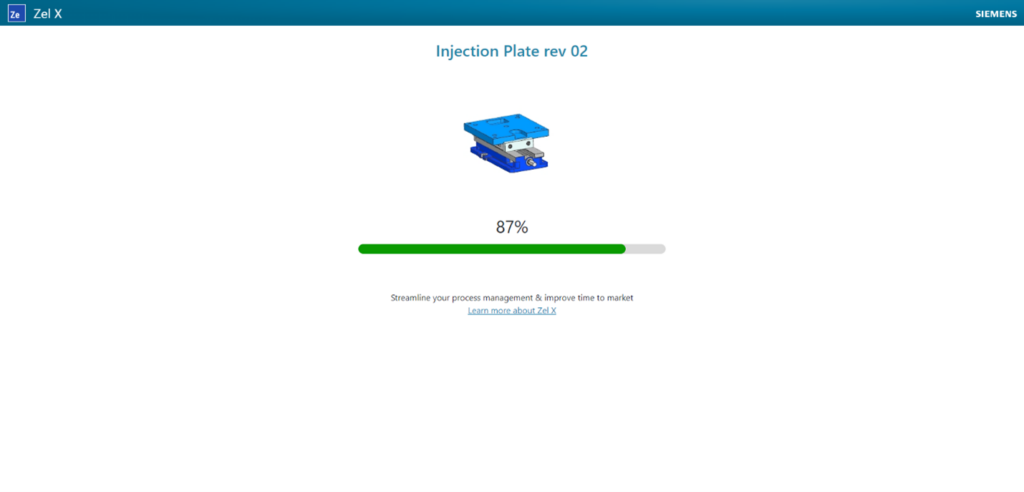

Easily assign stages to users as you design the manufacturing process to ensure the right person is working on the right stage at the right time. You can even set due dates for each stage of the process to ensure the job is done on time. If you have ever dealt with a customer calling every day looking for an update on the progress of their job, Shop Operations can share a simple progress tracking link with them, just input their name and email address and we will send them a link that allows them to dynamically see what the progress of their job is.

If you are working on a job that will be repeated, or just designing a generic process that can be used for multiple parts, such as a part family for example, you can save the manufacturing process as a template and re-use it on new jobs as many times as you need.

Zel X Shop Operations takes the traditional paper job traveler and makes the entire process digital. From designing the manufacturing process to walking through the shop at every stage, you can guarantee everyone has single-source access to the right shop floor data.

Everything you need, sized for your size business

Purpose built with exactly the tools you need to speed contract and part manufacturing, Zel X makes it easier to handle quotes, manage jobs and work orders, make parts, and collaborate with teams of all sizes.

The continuous release cycle of Zel X ensures delivery of those tools and functionalities as soon as possible, allowing your machine shop to move faster.

Browser-based, in an app designed with your needs in mind, Zel X helps your whole team can get started quickly so you can win more business.

Learn more about Zel X, click here.

Ready to try Zel X? Click here for a free 30-day trial.