The ease of setting up model-based CAM in Zel X

Table of Contents

In Zel X spend less time programming and more time machining with model-based CAM. For every complicated part in a tooling assembly, such as a mold cavity, there are dozens of other parts that are very simple in nature and require just a few machining operations. Holes, pockets, slots, chamfers, and open faces are the general feature types for these parts.

In such cases, the CAM (computer-aided manufacturing) software to create the required operations should be equally simple in nature so that a machinist can spend more time actually machining and less time programming. That is why Siemens created model-based CAM within Zel X, which can be used as a complete solution or integrated with existing computer-aided manufacturing (CAM) tools.

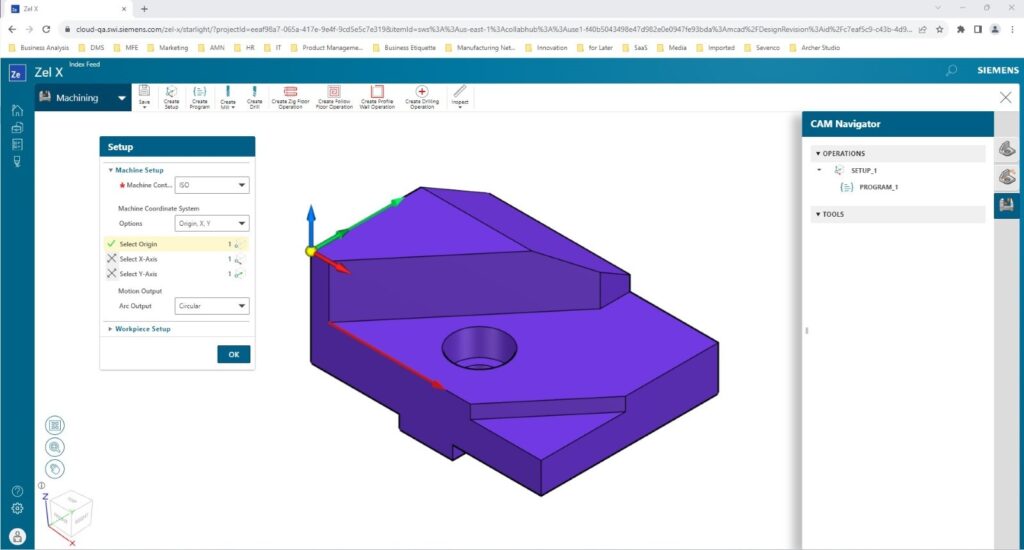

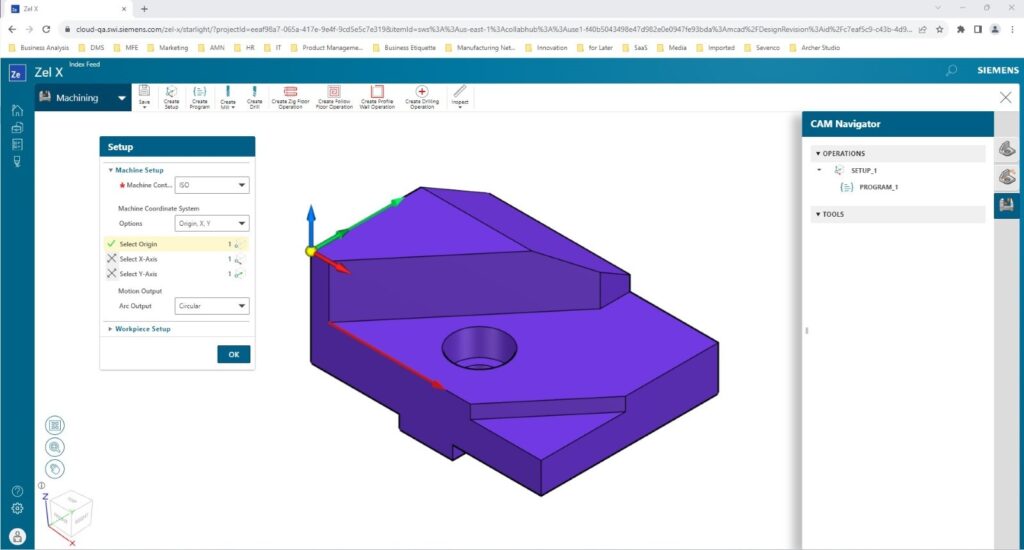

When entering the model-based CAM application within Zel X, a machinist is immediately prompted to define setup elements to represent the machine tool being used and the workpiece being machined. This is part of what Siemens calls the guided workflow. Instead of opening the software and being expected to know what sequence of buttons to push, accessing library-based CAM on demand in Zel X will aid the user with getting started. Expect little to no training required on the proper use of the software so that the user stays on course to getting tool path quickly.

Setup

The setup dialog guides a user to properly define elements required for tool path calculation.

Next, a user must define some cutting tools before jumping into creating operations, because there can be no tool path calculation without a tool. The options to define a tool’s shape are narrowed down to the absolute basics to streamline the process for the simpler operation types being created.

Tool

Only the minimal amount of inputs are required to define a cutting tool. Increase job shop efficiency with a simplified set of choices.

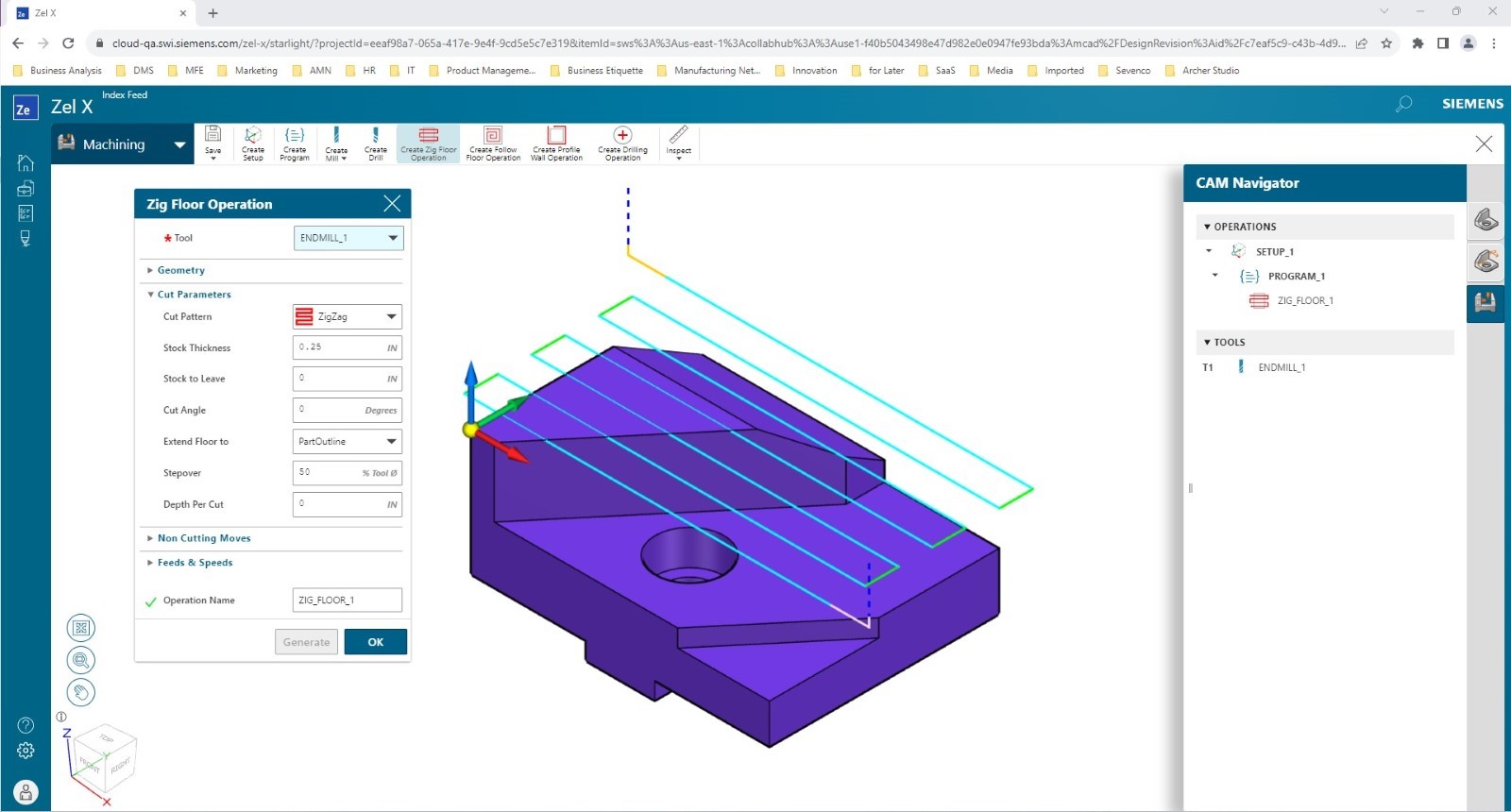

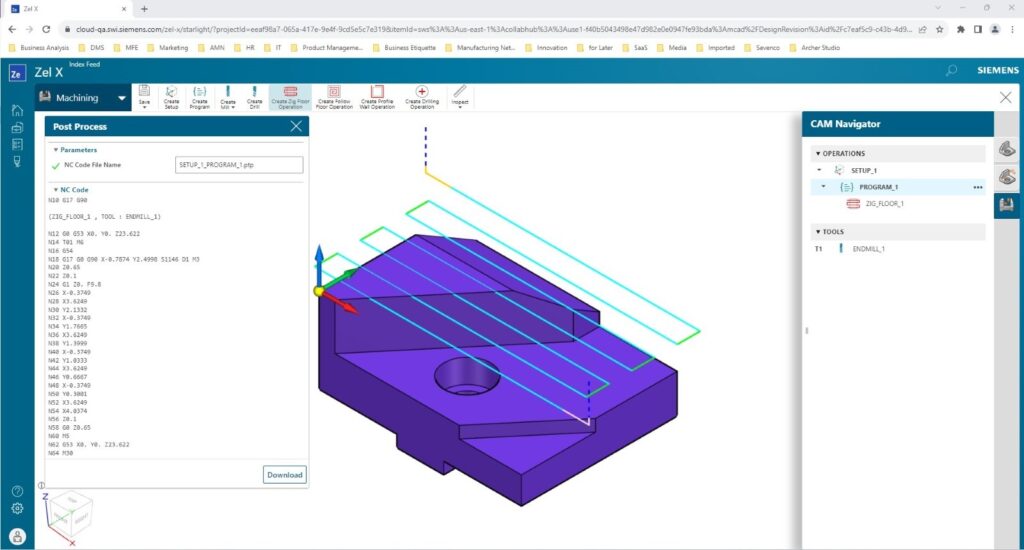

Toolpath

A tool path with a Zig Zag cut pattern is applied as a facing operation to the extents of the part outline. This is done with a single surface selection and without having to define any boundaries.

When at least one cutting tool is created, a user can start choosing operations and calculating some tool path. This version of model-based CAM in Zel X is targeted for machinists running a 3-axis CNC milling machine, so the operations available are for milling and hole-making types and are of the 2-1/2D type, meaning they can cut the simple, prismatic-shaped features. Each is contextualized for a specific geometry type and cut pattern so that a user needs to only select the cutting tool and feature to quickly generate some tool path and evaluate the results to accept or edit using a few available options.

The CAM operations are simple and easy-to-use, making it powerful enough to create multiple cutting strategies to fully machine a part. A machinist can cut all the features from rough to finish using just a few parameters to drive the tool path.

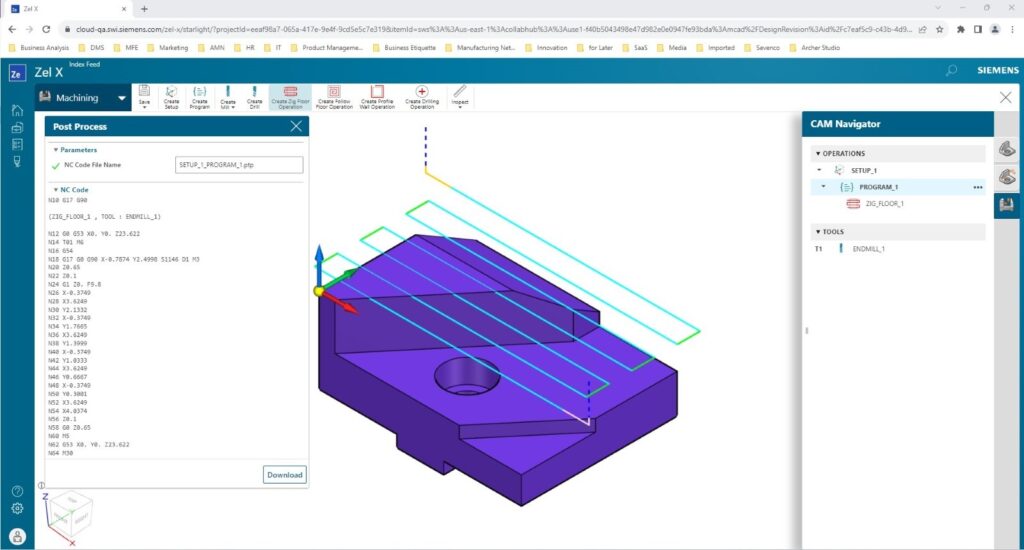

Once the desired toolpath has been created the machinist can post-process the G-code needed to start running the machine with. This is done instantly without having to search for a post file because of the previously required inputs in the setup definition. The software is intended to be used on-the-fly, meaning once the cutting begins the machinist can return to CAM in Zel X to continue defining the rest of the cutting strategy. This is a common workflow in most job shops as it is desirable to get the machine running quickly in cases of prismatic parts of low volume rather than spending time trying to optimize every motion for negligible cycle time savings.

G-code

G-code is post-processed instantly without having to search for a file or review a bunch of settings.

The software is also capable of multiple setups and multi-op post-processing to accommodate a user’s desired workflow. If a situation arises in which more advanced machining options are needed, the file can be downloaded from the cloud and opened within NX to continue with the desired cutting strategy.

Simple parts require an equally simple workflow. The software tools available should reflect this need. By reducing the number of inputs required compared to other CAM systems and embedding helpful guides to get the user the desired G-code more quickly, a machinist can spend more time adding value to the physical workpiece.

Everything you need, sized for your size business

Purpose built with exactly the tools you need to speed contract and part manufacturing, Zel X makes it easier to handle quotes, manage jobs and work orders, make parts, and collaborate with teams of all sizes.

The continuous release cycle of Zel X ensures delivery of those tools and functionalities as soon as possible, allowing your machine shop to move faster.

Browser-based, in an app designed with your needs in mind, Zel X helps your whole team can get started quickly so you can win more business.

Learn more about Zel X, click here.

Ready to try Zel X? Click here for a free 30-day trial.