Is there a simple way to identify compromised components?

New white paper covers a new solution for defective parts detection on the SMT assembly shop floor – where it really matters.

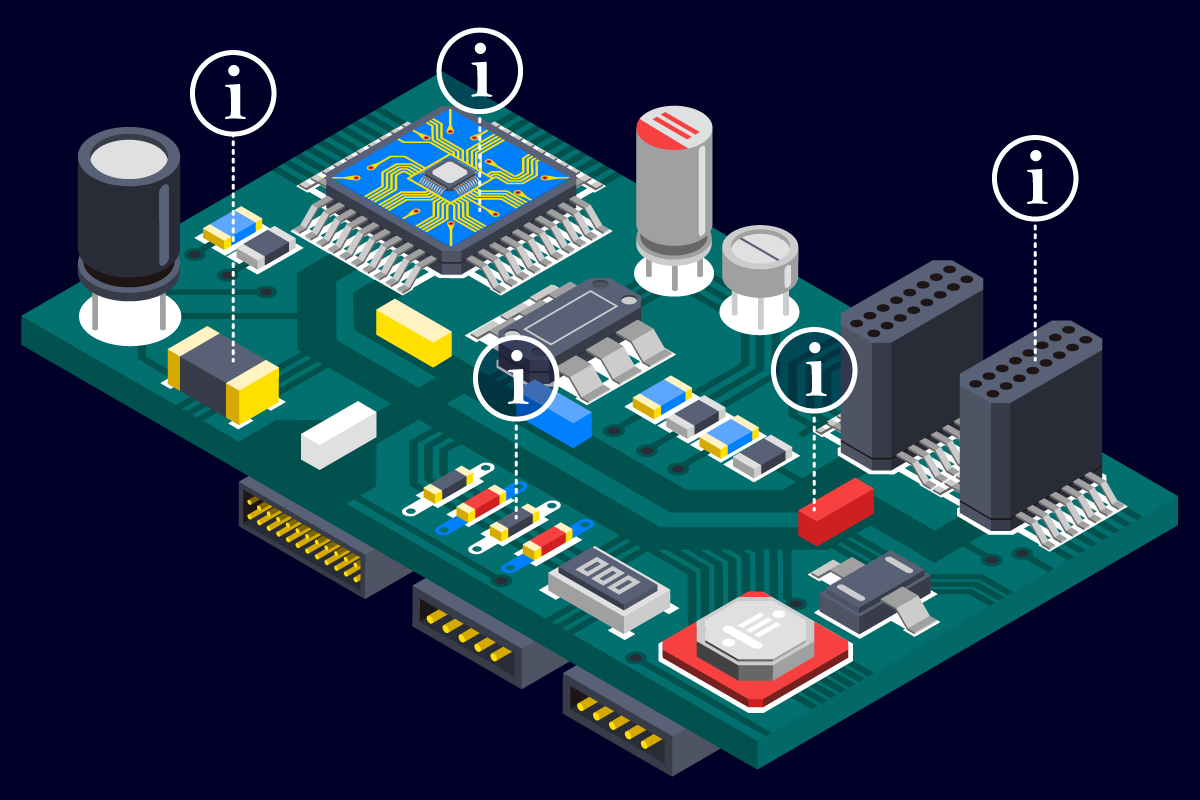

Tiny SMT components are almost invisible in a final electronics product, but a single defective part or compromised component can jeopardize an entire production run. Experts estimate that as many as 10% of components on the market today are compromised—either because they are entirely counterfeit parts, are delivered on mixed/non-homogenized reels, are expired, have been stored in improper conditions that impact quality, or have even been intentionally tampered with and embedded with malicious code. Manufacturers feel the impact of this problem in their profit margin—according to industry estimates, electronic defects are the cause of 0.5% – 2% of return merchandise authorizations (RMAs).

As supply chain problems force manufacturers to utilize components from various sources, it’s more important than ever for them to be able to verify component quality. However, until recently, no efficient component inspection solution was available. Manufacturers were forced to rely on costly, time-consuming lab tests that only looked at small samples and could not identify individual compromised components in a mixed source.

Siemens’ partner Cybord tackled this pressing challenge and created the first traceability solution that enables visual inspection of every electronic component in a machine. In the Cybord-Siemens solution, the existing images captured in the pick and place machines are compared to a massive component library and knowledge database in the cloud. Using AI models, the solution can verify component authenticity and identify damage/tampering and counterfeit components in 100% of the components being used—something that was never possible in the past.

Best of all, since the solution uses existing data, there is no need to introduce new operations. In fact, the entire process can be conducted while the SMT placement machine is placing the components preventing delays and slowdowns.

Download our new whitepaper to learn how the Cybord-Siemens traceability solution works.