The key to portable electronics manufacturing

Blog #5 in a 12-part series covering the Digital Twin Best Practices in Electronics Manufacturing mini-webinar series by Jay Gorajia

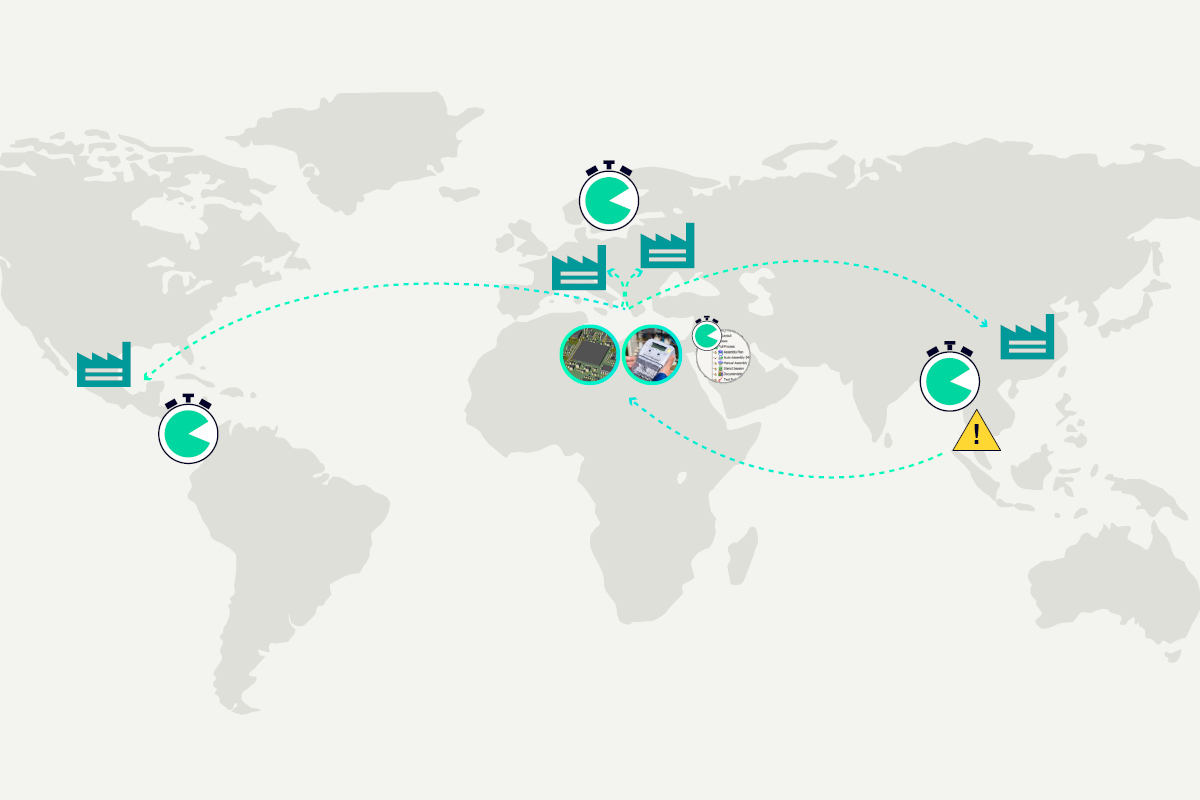

In conversations with the process engineers of multinational electronics manufacturers, we’re often asked if “digital twin” strategies can help them leverage their global reach to improve operational efficiency and quicken time to market.

These are some of the challenges they mention frequently:

- Critical component inventories are depleted, and long lead times for new supplies cause major production delays.

- A manufacturing site that is closer to the customer would reduce shipping time and costs, but the necessary expertise may not be available there.

- Production backlogs at the designated manufacturing site lead to delays, while available alternative sites may, again, lack the required expertise.

- No Plan B for shifting production from areas affected by unexpected events, such as a pandemic lockdown.

The common thread here is the need for portable manufacturing. Global manufacturers need the flexibility to move product production between sites. But it’s not so simple! For example, if the process preparation work was done at site A, how can it be leveraged at site B? Especially when a different set of machines is installed at each site.

And what about engineering changes? If a specific problem was overcome at one of the sites, how can we ensure that all sites will be able to access this knowledge in future projects?

In the fifth session of our series of 12 mini-webinars on Implementing “Digital Twin” Best Practices From Design Through Manufacturing we discuss how to achieve true portability of designs between manufacturing locations by establishing a “single point of truth”.

Main takeaways from the webinar session:

- How to leverage the portability of the ODB++ Process data format to normalize process data and facilitate its transfer between manufacturing facilities.

- How to use Siemens’ Teamcenter product lifecycle management software to manage a “digital twin” of the entire manufacturing project.

- How Valor Process Preparation establishes a single point-of-truth, generating a machine-agnostic production plan that is easily ported between from one site to another.