How to take control of your reflow oven processes

Siemens Digital Industry solutions provide crucial control and monitoring of smart ovens, and the entire shop floor.

Tracking the performance of reflow ovens is a challenging task. Generally, oven performance levels can be ignored… until quality issues arise. Then everything stops – while settings are checked, heating elements are examined, and boards are tested for usability.

In addition, board manufacturers, in order to comply with industry standards, are facing increasingly demanding process transparency, traceability and reporting requirements.

In order to meet these challenges, Siemens is working together with leading equipment manufacturers, such as KIC Embedded Designs, to provide complete monitoring solutions that will improve the bottom line, while meeting the most exacting Industry 4.0 requirements.

Siemens-KIC collaboration

Siemens and KIC have collaborated to produce a “Smart Oven” solution that helps limit downtime, reduces electrical and manpower expenses, and improves quality and productivity levels.

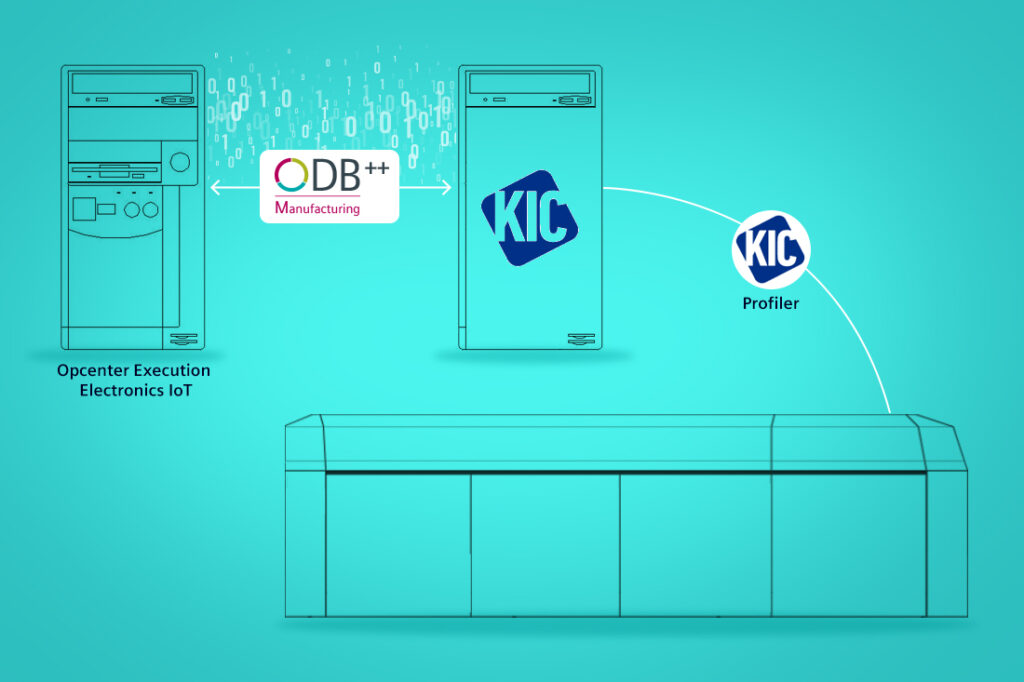

The solution integrates Siemens’ powerful Opcenter Execution Electronics IoT manufacturing data acquisition system with KIC’s thermal profiler. The KIC profiler obtains the oven’s thermal profile, and transfers it to a PC. The profile is then acquired by the IoT system, which aggregates live information for all the machines and processes on the shop floor. IoT is then used to manage oven profiles and settings, and provides immediate indications when anomalies occur.

Communications between IoT and the KIC Controller are accomplished using ODB++Manufacturing (ODB++M), a vendor-neutral, real-time communication standard for PCBA manufacturing systems. The ODB++M bi-directional interface supports recipe transmission, per-zone temperature settings and readings, and oven status indications.

The joint Siemens-KIC solution assures that the oven is configured correctly for every production run, and allows for immediate intervention in the event of a deviation from the required profile. The smart oven solution provides an impressive array of analytics-ready performance metrics, which can be used to enhance quality and customer satisfaction, while improving line efficiency and cutting costs. Finally, the solution meets the traceability and visibility that are required for compliance with Industry 4.0 standards.