Component Assembly Risk Assessment tool in Valor NPI 2403

Component Risk Assessment within a Manufacturing Driven Design environment

The component assembly risk assessment feature is a new addition to the Valor NPI toolkit that continues to strengthen Valor NPIs Manufacturing Driven Design offering, making it the most robust PCB DFM solution available.

With a Manufacturing Driven Design, Valor NPI brings specialized manufacturing knowledge into and throughout the entire NPI lifecycle. This allows designers and NPI engineers to have immediate and direct access to the knowledge of their specialists throughout the design flow, allowing individual and intelligent DFM reviews to happen at any all points of the process.

Component Assembly Assessment before placement

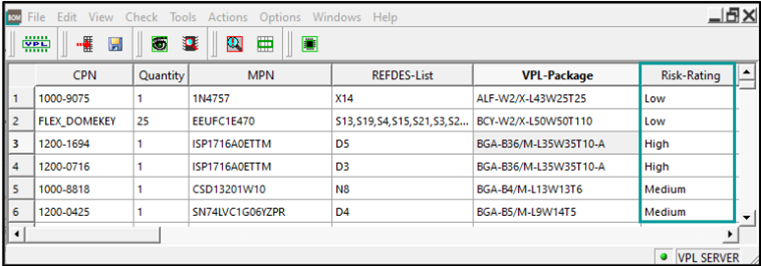

The Component Risk Assessment feature provides a BOM manager and PCB designers with a detailed look into the manufacturability of individual components, allowing for assembly considerations to be made during component selection. It allows your design team to consider alternate parts with lower risk factors during part selection, it allows the most problematic parts to receive priority during placement, or for design concessions to be made during routing.

Risk calculations are made on a component level and are performed on more than 250 billion parts currently available within the Valor Parts Library based on the physical characteristics of those parts.

This score represents the predicted solderability and reworkability of the individual components, with their scores placing them into generalized risk levels of low, medium or high. Risk alerts trigger based on a specified score within the software and allow for extra attention during design. An alerted component may require additional spacing, a different footprint design, or necessitate a BOM review.

In addition to individual component assembly assessment, the overall design is given a cumulative risk assessment score within the component section of the DFM report overview. Here a user can see information on the number of high risk components within a design. This provides a high-level view allowing a user to consider if the board as a whole should be considered risky from an assembly perspective. When performed on multiple BOM configurations using all available qualified parts, the component assembly risk assessment feature facilitates informed assembly yield considerations.

Component Assembly Risk Calculations

Each risk factor is assigned a grade based on the potential probability of creating a poorly soldered joint or the likelihood of the entire component requiring rework. The grade value is multiplied by a weight value to obtain the individual score for the factor.

Multiple weighted factors are considered within the score of this component. These are given a value from 1 (low risk) to 10 (high risk) all of the factors are given equal consideration, resulting in an overall score from 1-10. The recommend rating per score range is based on information aggregated from the VPL database, rating components like this:

| 0.1 – 2 | low risk |

| 2.1 – 4 | medium risk |

| 4.0 – 10 | high risk |

During the calculation, all the affecting risk factors are weighted equally. For example, the most common number of factors is five, therefore, each grade is multiplied by the weight of 0.2 or 20%. If the number of factors is three, then each grade is multiplied by the weight of 0.33.

If we consider a complex Fineline Ball Grid Array (FBGA) like the Altera Stratix IV, as shown in Figure 3, It would receive a score of 4.4, making it a high risk component. That score is broken down based on 5 of the factors considered with BGAs:

Component Package Type:

- GA – Grid Array

- Grade: 6

- Weighted Score: 1.2

Component Terminal Form:

- B-Butt or Ball

- Grade: 5

- Weighted Score: 1.0

Number of Terminals on Component:

- 1517

- Grade: 7

- Weighted Score: 1.4

Component Pitch:

- 1mm

- Grade: 2

- Weighted Score: 0.4

Component Package Size:

- 40mm x 40mm

- Grade: 2

- Weighted Score: 0.4

Total Weighted Score: 4.4

Component Assembly Risk: High

The final score for the package is calculated as the sum of the individual scores of all the affecting factors and risk score status assigned.

This detailed look into the assembly process of a board allows a team to make build and BOM decisions early based off of component lists alone to ensure designs start with high yields and greater reliability in mind from the beginning.

Explore the component assembly risk assessment more

The Component Assembly Risk Assessment, introduced with the latest version of Valor NPI, is the latest tool in Siemens unique Manufacturing Driven Design offering. By providing detailed assessments of component manufacturability, the tool empowers teams to make informed decisions regarding component selection, placement prioritization, and routing concessions.

To explore more of the component assembly risk assessment tool, or any one of Valor NPI’s offerings, sign up for a free trial at:

https://trials.sw.siemens.com/en-US/trials/valor-npi-for-any-eda-flow/