Talking Aerospace Today – Generative Design for Electrical Systems Part One – Transcript

In this episode of Talking Aerospace Today, Todd Tuthill is joined by Anthony Nicoli to introduce the concept of generative design in the context of digital transformation maturity and begin exploring its presence in the domain of electrical systems.

Patty Russo: Greetings and welcome to another episode of Talking Aerospace today from Siemens Digital Industries software. I’m Patty Russo and I’m responsible for global marketing here at Siemens for aerospace and defense. Thank you for joining our conversation.

Patty Russo: After recent episodes, we’re well into the discussion of digital transformation maturity. We’ve covered how companies can automate their engineering processes, and in our last few episodes, we talked with a special guest, Justin Hodges, AI/ML technical specialist and product manager here at Siemens for Simcenter. He talked about where and how AI could be applied throughout this whole journey. Next, we’ll get into the meat of digital transformation maturity, generative design.

Patty Russo: This is a vital stage for digital transformation that impacts multiple aspects of aerospace design. So today’s conversation is only the first. We’ll have more, but today’s conversation will focus on generative design in electrical systems. But first, please welcome back our VP of Aerospace and Defense at Siemens Digital Industries Software, Todd Tuthill. Welcome back, Todd.

Todd Tuthill: Hey, Patty, great to be back.

Patty Russo: And joining us today for this episode as our guest, Anthony, or Tony, Nicoli. He’s our senior director for aerospace at Siemens and we look forward to hearing his insights about generative design for electrical systems. So welcome, Tony.

Anthony Nicoli: Thanks Patty. Thanks Todd for inviting me to join you guys today.

Patty Russo: Alright, so let’s dive right in. Todd, as we mentioned, we’re well into the topic of digital transformation maturity. We’ve discussed multiple forms of automation. We’ve covered how AI will fit into the wider journey. Can you give a quick rundown of what we’ve covered so far and how today’s topic fits into all of this?

Todd Tuthill: Absolutely. And I was thinking of a different way to describe this, because we describe it- the same thing in various ways and we’re so far along here. Let’s pretend today that we’re building a building. Okay? We’re constructing a building and it’s going to be five stories because there’s five steps, and the first floor we’ve already constructed, it’s called configuration. It’s kind of how you start your journey in digital transformation maturity. You know, going from document-based to model-based and adding some configuration. That’s kind of floor one. We built that. That foundation is there. And then we build the second floor as connection, and that’s where you have multiple domains and you put them together so they can connect. And as we’ve said, building the first two floors of our building is pretty labor intensive. That’s one of the big issues that we’re seeing in aerospace right now is the absence of labor, and engineers and technicians that do all the work.

Todd Tuthill: So that’s where floor three comes in, automation, where the computers, the software, begins to do a lot of the mundane work that the engineers and the technicians would normally do to design and build these aircraft. That’s the first thing. And then the second part of automation is, you know, after we do the mundane things, the things people don’t want to do, the second part is to really start to do the more complex things that we used to think that only that only engineers and people can do. We call that authoritative automation. And that’s of course enabled by artificial intelligence and machine learning. And that’s kind of the third step and that’s where we are so far in our discussions, in our podcast.

Todd Tuthill: Today, we’re going to kind of take the staircase and start building the fourth floor and really get into one of those topics that we would have traditionally said only people could do. And that topic is generative design. So that’s the fourth floor of our digital transformation maturity building, generative design. That’s the topic today.

Patty Russo: All right. So before we go further, let’s pause for one minute and talk about generative design. We’ve tossed that phrase about in the industry quite a bit. Some listeners may already have their own idea of what it means. Todd, what does generative design mean in the context of digital transformation maturity?

Todd Tuthill: Well, we’ll talk broadly just, generative AI. It’s a field of artificial intelligence that really takes me uses machine learning and takes some kind of typically natural language input and produces something that didn’t exist before, adds on to something, maybe adds to it, creates something new. It could be text, it could be software, it could be images. In this case, we’re going to talk about design. I happen to be a photographer and I’m an Adobe Photoshop user, and if anybody’s looked at what Adobe’s released in their beta version of Photoshop lately, it’s pretty incredible. And it’s a great example of generative design in adding to a particular photograph. You can draw a box, put an actual language input.

Todd Tuthill: You know, I want- Let’s say you draw a box on a photo you took of the ocean, draw a box, say “I want a sailboat,” and poof, sailboats appear. And that’s a simple example of generative design. A more complex example of generative design, give you an example from aerospace, something from my career. Prior to coming to Siemens, I was at a previous company and I was a user of some of the products that our guest today is going to talk about. We’re going to talk about electrical systems. And I was using a key aspect of a key product for electrical systems. The product’s called Capital, and it does wiring design and Tony will get into all that. I won’t talk about that. He’s in a much better place to talk about that than I was.

Todd Tuthill: But the thing that we were trying to create this previous company, I wanted what I called the easy button, and what we were working on, we had we were doing architecture development in a SysML tool and we were spending hours, sometimes hundreds and hundreds of hours creating schematics. And I said, “Gee, let’s see if we can come up with a way to auto generate those schematics.” And we were going to connect the SysML tool to capital with an easy button. And I said, “I want to push a button and I just want the schematics to appear.” Well, unfortunately in my previous company we never really got there. I was looking for the generative design kinds of things we’re talking about today.

Todd Tuthill: That was a few years ago. I think things have advanced and here we are, and I think now I’m really interested in hearing from Tony because I think some of the generative design things I’ve been looking for in my career in past in a past life actually exist now, and that’s why I’m as excited to listen, as I am to participate. So that’s kind of the basic idea of generative design. Taking some things that exist, some rules, some machine learning, put in some basic natural language and have new things kind of appear. That’s the basic idea of generative design.

Patty Russo: Awesome. And that’s a great analogy, Todd. We all want an easy button for everything in life, right? But in this case, Tony, from your experience, do you have the answer to the easy button? Are there any tools out there that can do these sorts of things now, and if so, what do you see as a potential impact or benefit for companies?

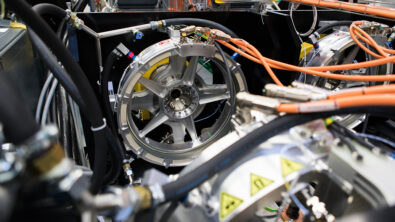

Anthony Nicoli: Well, Patty, I’ve never known there to be an easy button, but I think I’ve got an easier button. So I work in integrated electrical systems, and we focus in on helping aerospace and defense companies integrate the electronic and electrical systems that actually make modern missions possible. And we have developed a tool over the course of the last 20 years called Capital, which is a tool that actually enables the implementation of electrical systems across a number of different EE disciplines. Electrical integration, network integration, software development and electronics integration. And we’ve had generative design in mind from the get-go of developing this environment and it is available today and it is actually impacting our customers productivity and major ways right now.

Anthony Nicoli: For example, you may be familiar with the James Webb Space Telescope that Northrup Grumman put together and launched with the NASA not too long ago. They used Capital on that program and they were able to increase the overall workload by 30% without increasing the number of people on the program, and they also increased the overall efficiency of their program by 50%. So there’s major impacts in productivity that can be had by moving towards generative approaches.

Patty Russo: Tony, let’s talk a little bit further about the solutions that you touched on. How are some of the tools able to help customers deliver on generative design today?

Anthony Nicoli: Yeah. So, if we focus in on the electrical discipline itself, which integrates mission systems and avionics systems in the platforms, in this task, people start with requirements for functional execution and then they move all the way to putting in place the wiring and the harnesses that actually implement the interconnections between all of the systems and the LRUs on a platform. And what we’re able to do today is apply generative algorithms to connect information along the development life cycle. So let’s say you start with a set of requirements, and you get them into a series of system models, and you’re using something like Rhapsody for system- with SysML. You can automatically take your result, your model result, press Todd’s easy button and turn it into a logical schematic of the implementation of the system.

Anthony Nicoli: And the reason that I say it’s an easier button and not an easy button is because it’s never 100% done when you get it into the next stage. So, what you’re really doing is augmenting the productivity and the creativity of that next person’s work, right? So the logical system designer now can focus on where they actually add value and enrich the design as opposed to rekeying everything in and wasting all their time and getting bored and then wanting to leave the company. You know, all the things that are not fun about doing development. So they start at a much better starting point, and then they put in their intelligence to actually enrich the design at that stage of the development process.

Anthony Nicoli: And then they can pass it to the next person. And again you hit the button, you move it down, you generate now a wiring diagram off of the logical piece, and then the wiring designer may enrich it. We do it again as you go into specific harness design where all the mechanical elements and individual lengths and all the wires are chosen and all that sort of thing. And then you can vault that stuff away into either the environment that Capital provides or up into your PLM, you know, to Teamcenter and the seams accelerated backbone and all that stuff is done in an automated fashion.

Patty Russo: So Todd, does that sufficiently address your easy button solution?

Todd Tuthill: It certainly does. It’s something I would have loved to have had in a previous life. But you know, to Tony’s credit, he kind of casually says, okay, we’re doing all these things, but I want us to really think about the incredible place that these technologies put our industry in right now. I mean, think about it. Tony reeled off some numbers there. I think there were 30% here and 50% here. As we talk about digital transformation maturity, we talk about return on investment and we talk about value for deploying a new process and a new set of tools. Tony said it. It’s not just generative in the aspect of schematics, but it’s all through the development process, the manufacturing process, and the supportability process. And it’s just so, so many ways to save time and money the first time through, but as anybody who’s been in this industry for industry for a while knows, you don’t typically design something once. You design it, you change it.

Todd Tuthill: There’s variance. There’s problems all along the way, once you set this data set up once, well, it’s going to help you the first time and make the first time through faster. It’s going to make the second, third, fourth and 17th time, you know, orders of magnitude faster, and not just faster, but more accurate. It’s just so many levels of return on investment of making things better. It is the, you know, the, I’ll say, if not the easy button, certainly the path to the easy button that I always looked for when I was leading design teams. It’s a great time to be in aerospace and great opportunities to really have these kind of tools that, you know, because you think about, we talk about in a digital transformation a lot that many times we have for years just digitized the way with the manual processes and paper that we used to use.

Todd Tuthill: A time was going to come when we were going to get to something that only a computer could do that we could never imagine in doing manually. Well, to me, generative design is kind of the bridge to that, that idea of now we’re doing things that only could ever be done on a computer and maybe Tony, if you could talk about that, you know- You’re excited by that.

Anthony Nicoli: Yeah, I am excited because, so I talked about this generating these tech manuals, right? Well, I can’t tell you the customer, but we have a customer who literally eliminated 94% of the time to generate their tech manuals. You go, “94% time well, maybe that’s like nothing.” No. I don’t know if everyone knows about the changes that took place in the EWIS regulations for compliance back years ago now. For a lot of years, the aircraft manufacturers were able to avoid their full application because of grandfathering and derivatives of old aircraft. Okay? Moving aircraft forward, and it’s not like we were unsafe. It was fine. It’s all under compliance and safe. But the new generation of aircraft has to conform to them completely and they really explode the amount of data that has to go in these tech manuals and these service pubs, and they literally went to tens of thousands of person hours required to generate these tech manuals.

Anthony Nicoli: I mean, imagine how much money and time that is, and then imagine all the errors they have to solve. They went to a few hundred hours by applying our generative technology, and they think they’re going to be able to get to under 80 hours soon. So we’re talking about improvements that are, like, so dramatic, management staff don’t believe it. Right? They go you can’t come to them with these ROI numbers because they go, “I don’t believe you.” So the great thing about that is that it lets you underestimate and, you know, overdeliver and get a raise.

Anthony Nicoli: It’s a great thing. So, you know, the it’s it seems crazy when we think about this, right? That this kind of capability is possible? But it is. It’s here and it’s now, and frankly, this stuff is a young technology. It is- We’re just getting going on applying all of the great things that are happening in AI, ML, and other places to extend the generative algorithms that are already in place. I think that when we talk about digital transformation, it really is going to be a transformation, and it’s going to liberate us to be able to do the things that we always wanted to do. The easy button is not going to be used to like get rid of the modern workforce. It’s going to be enabling people to do things that they only aspired to do and could never have thought they could get to. It’s a wonderful thing, honestly, where we’re headed.

Patty Russo: You mentioned before engineering augmentation, and to me that’s a great phrase to sum up what you just said, especially as it pertains to the time savings and the workforce issues that are industry faces. The engineers that are out there, I’m sure want to be doing engineering, not some of the things that are more mundane, and in those cases where we’re eliminating that much time, you know, they’re eliminating 94% of the time to generate technical manuals. Look at the potential to reengage that workforce that was doing that to do more interesting and engaging things. So yeah, it’s super exciting. And then the other piece of that is just looking at understanding the complexity of wiring in the products and aircraft that we’re producing in our industry, that’s such a huge issue and being able to streamline some of those things are, you know amazing.

Anthony Nicoli: We could have a whole session just on that, Patty. Right? Because it I don’t know if people realize this, but if you look at like modern commercial aircraft coming down the pipe in the production line, their electrical systems, the mission systems and avionics systems and the implementation of the electrical system can vary over 50% from unit to unit on the line. So it’s not like you just design it once. You have to design, as Todd was saying, design and redesign at the rate of your production, and that rate’s only going up, go look at the data. Right? Everyone’s targeting to go to like 80 a month or 100 a month. That’s a lot. That’s a lot of redevelopment. And then all that stuff I talked about, all that manufacturing stuff, all that service stuff you got to do that for every one of those. So it’s becoming a kind of an imperative, I think, more than an opportunity.

Patty Russo: For sure. Hey, Todd, is there anything you want to cover before we wrap up this episode because we’ve got a lot more that we can talk touch on, but I think we need a second round.

Todd Tuthill: Yeah, there’s a lot to say, but I think maybe we should leave it there because I’m looking at the clock and we’re- So I’m probably just going to stop right there and we’ll pick it up in the next episode.

Patty Russo: So it’s a great discussion as usual and I always learn so much. But as Todd said, this is a great place to pause this part of the conversation. We will pick it back up in our next episode. Meanwhile, please be sure to check out the show notes, the blogs related to the Talking Aerospace Today series, and as Todd mentioned at the top, other episodes. Special thanks to Tony for joining us today. Thank you, Tony.

Anthony Nicoli: Thank you guys.

Patty Russo: And thank you, Todd, for another great episode. I’m your host, Patty Russo, and I look forward to having you join us for our next episode of Talking Aerospace today.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.