Industrial Machinery – a writer’s year in review for 2023 – pt. 1.

In revisiting some of the more notable industrial machinery blogs and articles of 2023, I begin with a hot topic aggravated by the pandemic over the last three years, as we addressed How to sync production supply chains. I spotlighted two white papers, the first one focuses on the following four areas:

- Volatility in a shortened product lifecycle with scarce resources hinders planning supply processes.

- Uncertainty intensifies macroeconomic developments: rising energy prices, strikes and higher labor costs.

- Complexity in logistics operations stems from more significant production variability and growing volumes of data.

- Ambiguity affects data interpretation in performance, productivity, and cost pressure.

Managing these issues requires syncing production and logistics synchronization that coordinates tools to plan and control process flows.

The second blog promotes the white paper, Supply chain resilience, teaching us how to cope with current challenges and threat scenarios while strengthening the supply chain’s resilience. Notably, we learn how to achieve a robust and reliable supply chain, even under pressure.

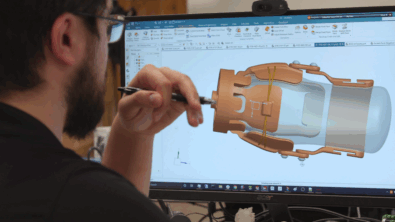

Another remarkable topic is the digital twin – an ongoing theme and technology occurring as part of smart manufacturing and smart industries today. My Digital Twin and New Dimensions in Logistics blog promotes a white paper discussing how a digital twin is an essential element to the crucial building block of digitalization in logistics, as they intensify with better utilization, concept planning and reliable goal attainment.

Sustainability is another hot-button issue. We produced a five-part podcast series with our industry experts discussing sustainability’s impact on all industries. In part three of that series, Sustainability and a Holistic Viewpoint, we discuss the four trends driving change in the industrial machinery industry. We learn how sustainability in manufacturing machines is essential to evaluate how suppliers will provide parts for machines and how sustainable their efforts are in making those parts by measuring the sustainability impact from operating machines at the end of the day when running a machine.

In part four of the sustainability series, Sustainability and the digital twin energy resource impact, we focus on machine operations and sustainability, studying its effects in factories and machines.

Finally, in our fifth and final episode in the series, Sustainability of Energy and Resource Efficiency, we discuss the overall challenge in the scope of the sustainability journey, which is not to have a few people doing it perfectly but requires everyone to do it imperfectly – start it and get it going. It’s not about hiring four people as sustainability experts, but it’s infusing sustainability and environmental protection considerations into every role in your organization.

We will continue to discuss other topics covered over the past year in a subsequent blog. And we look forward to exploring new, challenging, and intriguing issues in 2024 that will positively impact the success of the industrial machinery industry.

Related links

Industrial Machinery – a writer’s year in review – part 2

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.