Energy Transformation summary – unpacking Siemens Digital Lifecycle Excellence – part 1

The new Energy Transformation podcast series was launched in March, introducing the first podcast episode in a four-part series. The moderator, John Lusty, Industry Lead for Energy and Utilities Industry Marketing at Siemens DISW, joined John Nixon, Senior Director for Global Strategy at Siemens Digital Industries Software.

In this series, John Lusty and John Nixon walk us through illuminating Siemens as a software company because many people do not realize that Siemens produces software. They explain Siemens’ philosophy of a lifecycle approach to enterprise data management and the Xcelerator platform.

In this first episode of the Energy Transformation series, they discuss the digital thread and provide a better understanding of Siemens Digital Industries Software and the Digital Lifecycle Excellence approach to data management in the Energy and Utilities (E&U) Industry. Enjoy!

>Listen to the audio of the first Energy Transformation Podcast.

Siemens organizational structure

Many people may be familiar with Siemens as a corporation, known as Siemens AG, which provides control systems, automation, and equipment such as turbines. However, Siemens is a network of organizations that are a multi-billion-dollar corporation, a giant software company. Many assets utilized in Siemens’ facilities get used in people’s day-to-day lives, all produced, designed, optimized, and perfected for manufacturing using Siemens Digital Industries Software.

When discussing Energy and Utilities as part of Digital Industries Software, about eight segments are combined in Siemens Energy. For example, oil and gas production, pipelines and storage, power generation and utilities make up the energy segment. In the chemicals area, there are refining chemicals and polymers. In addition, there is glass, cement, and rubber in materials, and mining and metals upstream. Also, within E&U, they touch on AEC – architecture, engineering, infrastructure, water and wastewater.

In recent years, Energy and Utilities have incorporated new business ways. The philosophy at Digital Industries Software is based on a lifecycle approach to data management, so industries such as automotive transportation produce discrete products and assets that design and decommission them; similar to E&U, where customers may operate facilities for decades. Simultaneously, it’s necessary to distinguish the strengths in capturing data and documentation that supports the initial conceptual design of a product, asset, or project throughout its entire life cycle through design, construction, commissioning, operations, maintenance and eventually decommissioning. This lifecycle approach is typically new to the E&U industry. However, it offers a significant model from an enterprise data management perspective.

Furthermore, it is essential to maintain a lifecycle from concept through operations to prevent any problem areas. This process includes tracking procedures, gathering data, and material quality through installation, assembly, construction, commissioning and operations. Therefore, when issues arise, one must quickly and forensically go back to the lifecycle of these assets to understand the problem and prevent future occurrences. The lifecycle approach possesses the answer to quality, safety and environment.

Environmental, sustainability (or social), and governance are significant issues and a profound topic within Energy: ensuring a lifecycle from concept through operations to prevent and prescriptively address operations and maintenance. And, most importantly, to learn from any issues that arise and move on.

For example, in 2010, an explosion occurred in San Bruno, California, at a pipeline maintenance company that killed eight people, causing billions of dollars’ worth of damage. It was a 30-inch natural gas line that ruptured within a neighborhood. But, when performing forensic analysis of the welds for that pipeline, no lifecycle was associated with it in the company. So, it was impossible to validate the material condition used during the weld. And it was not feasible to validate the weld procedure or the people that performed the welds.

Consequently, it was impossible to know if it was an operator issue, a material issue or how many other welds were compromised. This is a prime example of why a lifecycle approach is essential. It is crucial to maintain a lifecycle from concept through operations to prevent these issues. For instance, when tracking the procedures, gathering data, material quality, and more, there is a process through the installation, assembly, construction, commissioning and operations. Furthermore, if issues occur, it is essential to forensically go back to the lifecycle of these assets to understand why the problem happened and prevent it from reoccurring.

It is crucial to consolidate the systems of systems, bringing individual applications from a diverse network, obtain the output with a high level of intrinsic value within that data and consolidate it. Siemens knows that every industry has similar problems, so they developed a toolset called Xcelerator – the ideal solution that a customer uses to manage all data that must be highly comprehensive, open and flexible. It is essential to support open standards so that information flows from each discipline, bridging the gaps between silos, eliminating the Excel spreadsheets, and confiscating that value so the owner-operator cannot ultimately reuse it.

Siemens Xcelerator platform is a broad toolset

Xcelerator is a toolset that supports business operations, depending on the industry and the business model that a company is maintaining. Whether an owner in the oil and gas industry, power generation, a turbine designer or an EPC, Xcelerator captures the output and makes it available to the segment of the equation that has the most complicated task – the owner-operator.

Siemens Xcelerator platform of solutions delivers results. And the E&U group creates digital threads, which are solution sets that work together comprehensively and flexibly. Also, they can personalize to help customers: owner-operators or OEMs to deliver on their business model. The first one that Siemens E&U rolled out is Digital Lifecycle Excellence, which describes the lifecycle approach to technical enterprise data management, providing business value by consolidating information, validating that information and making it available to knowledge workers.

This process is the foundation for all future business requirements and supports assets. But it’s a day-to-day challenge when people in the field inspect assets and gather data (including sensor data). In turn, it is a monumental task to gather these copious amounts of data to collect, manage, analyze or determine the problem areas. Previous methods used three-ring binders and paper to document the findings or perform hydro test, x-rays and ultrasonics – with various forms of testing ongoing in the field to operating assets while results were manually recorded.

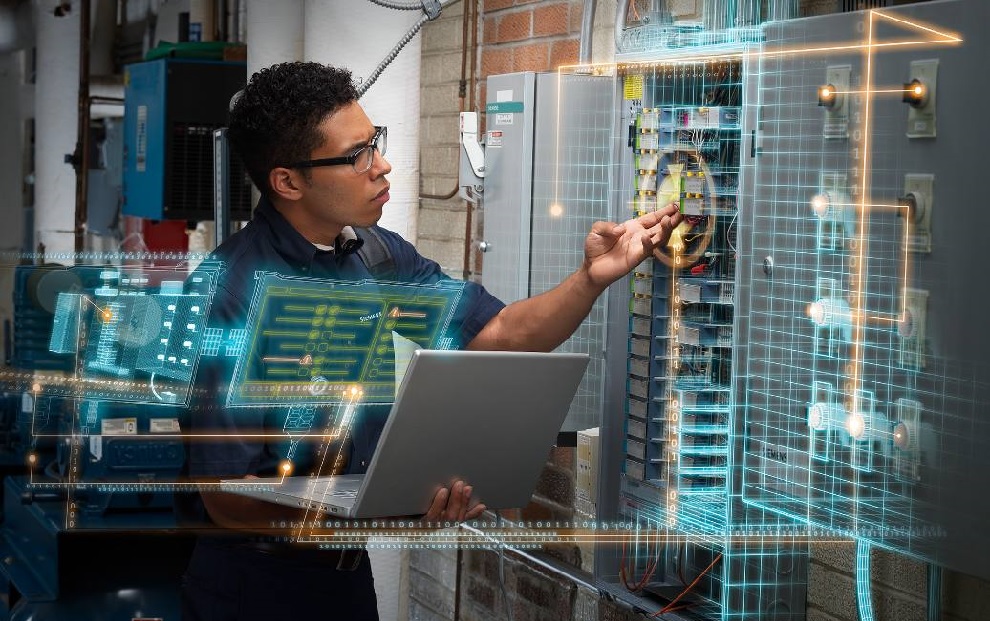

So, there is now a demand to drive and bring that data back for a digital twin to match the physical reality in the field – a preeminent challenge. Xcelerator beautifully communicates Siemens entire suite of solutions: gathering the data, analyzing and prescriptively looking at ways to mitigate issues.

Decarbonizing our entire supply chain as a planet – energy transition

Additionally, when you look at Digital Lifecycle Excellence, it decarbonizes the entire supply chain as a planet. Because there is no planet B for earth, the focus is on consuming oil and gas and processing of mined materials. The entire supply chain is looking at their carbon footprint and the generated waste. Twenty-four percent of all solid waste is produced from the construction industry, even in the United States. By 2024, 2.2 billion tons of solid waste will generate in construction projects. Therefore, it is necessary to take a detailed lifecycle approach to mining, refining, applying and developing this infrastructure that keeps society moving forward as a species – it must use Digital Lifecycle Excellence throughout the entire process. When thinking about lifecycle, it starts with a concept and design. So, the design must come out of the development and the delivery in the field – the carbon, the waste. When the development of that carbon and waste goes into construction, it is essential to minimize that carbon and waste development, moving into maintenance operations. Then comes optimization to reduce the development of carbon and waste. Digital Lifecycle Excellence is a vital effort from concept through operations to help solve these issues.

Knowledge workers must be armed with the correct tools and assets, with value at inception, that is provided end-to-end in the lifecycle, positioning them to solve challenges in the energy transition.

The current generation of workers coming into this industry are raised on Xbox, PlayStation, and iPhones; therefore, they have raised the bar with great anticipation of the digital frontier they will expect to find in the energy industry. A digital twin and a digital lifecycle view of this industry mean that customers and companies must attract exceptional talent. Therefore, the industry cannot be 10 or 20 years behind.

Also, tools must track users, as the industry is competing against the best in the business: like Google. It is essential to attract potential employees to replace retirees at an increasing rate until 2030, offering the same tools that NASA and SpaceX are using, but in oil and gas. It’s an exciting dynamic as maintaining the supply of Energy is about maintaining life. Nothing is accomplished without Energy. Therefore, it is an imperative challenge to society and the industry.

Learn more in the first Energy Transformation Podcast.

For more information, check out the Digital Lifecycle Excellence webpage at www.siemens.com/dle.

Connect with the experts on this blog topic: John Nixon and John Lusty, on LinkedIn.

Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram. Siemens Digital Industries Software – where today meets tomorrow.