Improving additive for industrial adoption

Additive manufacturing is a favorite tool of hobbyists, it provides a one stop solution to bring your designs into the physical world. But the capabilities of what many of these home solutions provide are far from what is needed for industry. Printers for home use, require that you get a hold of separate modelling software, they are often limited to three axes unless you can create your own rotator and program the g-code manually and without spending multiple times over the cost of a home printer, build prep is done by hand. For using AM at scale, none of that is acceptable. Fortunately, Siemens is hard at work solving these problems to provide a painless path to adoption.

Integrating the virtual and physical

The world of industrial purchasing is far different from consumer, but that doesn’t diminish the importance of EOS North America reselling AM software with its 3D printers. By integrating the digital and the physical on day one customer can successfully print their first part and well past their ten-thousandth. The integrations between EOS printers and Siemens software enables customer to generate EOS build files directly in NX and offers previews of the fill patterns on a layer-by-layer basis before generating the print files. Not only does this advancement solve the problem of disconnected virtual and physical environments, it begins to streamline the build preparation of AM components to save that engineering time.

For more information on this partnership and how it is accelerating the adoption of AM in industrial environments, Aaron Frankel’s Advancing Additive blog #11 is a great source for the specifics.

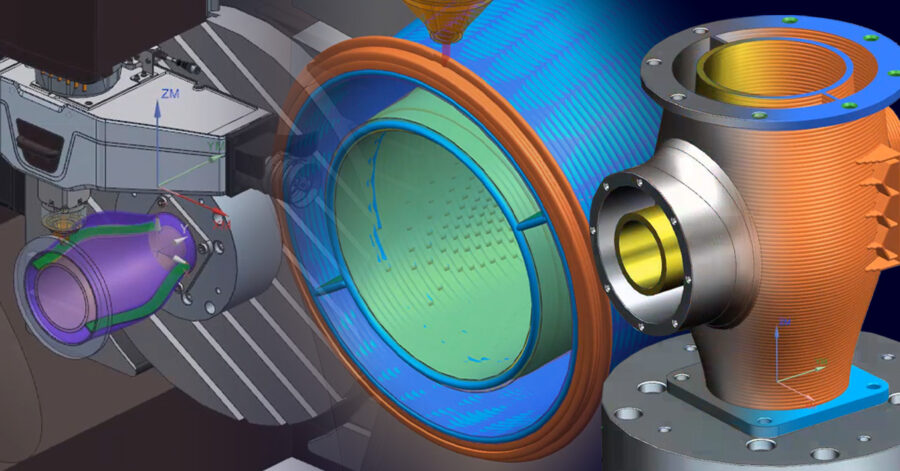

Smoothing prints with 5 axes

5-axis printing is almost commonplace for CNC applications, but most 3D printing has been relegated to just those three dimensions. Some innovative folks have augmented the 3-axis solution with a turn table to approximate 5-axis, but the quality can’t compare to a full simultaneous 5-axis solution. And upgrading does not necessarily mean buying a brand new 5-axis direct energy deposition printer, utilizing a comprehensive software solution can often be the solution. By integrating all 5 degrees of freedom into the toolpath creation, the end result will be much smoother on the surface, and it will provide more functionality because the complexity of translating g-code is left to the software.

Software support for 5-axis tooling also translates well for hybrid manufacturing machines using AM and CNC milling, for more information read Advancing Additive #12.

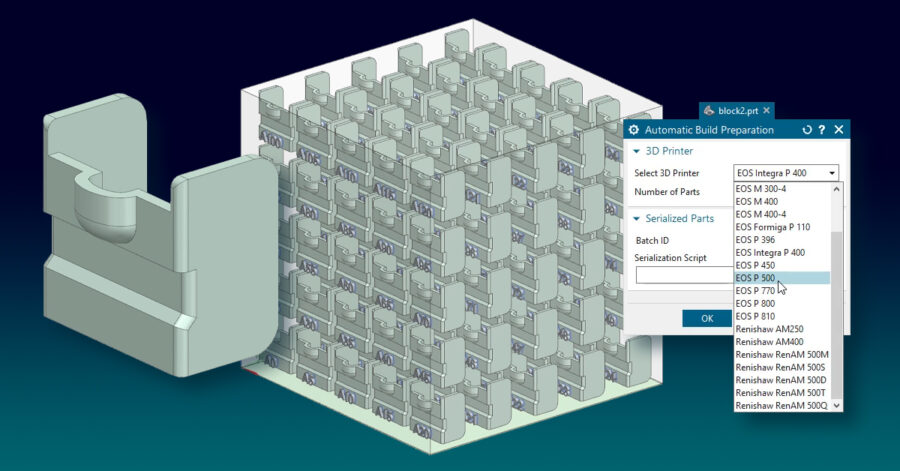

Automated build preparation

The speed of manufacturing is directly related to the level of automation. People are amazing at solving problems and quickly switching tasks, but when it comes to speed machines are unbeatable. This is especially true in the case of build preparation of AM parts where fitting as many parts into the print area is a 3D jigsaw puzzle. Automating this task saves engineers hours of monotonous work retrying configurations to fill the print bed where a computer can do it in minutes. This automation also makes printing an easier job for the employees on the shop floor, once the design is qualified it is practically a push button effort to start printing. And all of this is without taking into account optimal print orientation, a task almost impossible without a comprehensive simulation environment. And for extra steps like serialization, the process can be written to a script that captures the workflow. This can be reused later with the option to edit most of the parameters for output generation.

This is only a taste of what is possible, for the full story read Advancing Additive #14 from Aaron Frankel and learn how Siemens Software is accelerating industrial adoption of additive.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow.

Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow