Siemens takes the street view principle to production planning with Intosite

Co-authored by Alexander Eisenmeyer and Yonit Doanis of Siemens PLM Software.

To production with the click of a mouse usingIntosite.

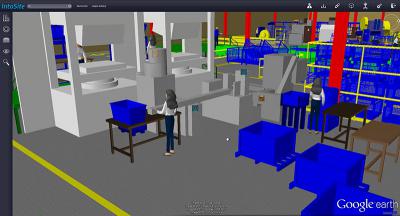

Today we can take virtual city tours right from our desk, and use the computer mouse to navigate through entire cityscapes of photo-realistic 3D pictures – thanks to the Internet. Google Earth and street view have familiarized us with this idea that Siemens has now translated into a solution for industry: Without leaving their offices, production managers and planners can take a tour of their facilities across the world at any time for the purpose of optimizing their processes.

IntoSite enables collaboration and knowledge sharing between departments and factories using geographic information system (GIS) capabilities.

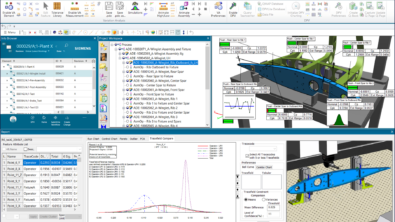

The number of applications using 3D models and virtual simulation keeps growing rapidly. Now a Siemens team in Israel has developed IntoSite, software which allows users to navigate through a photo-realistic 3D representation of buildings and production facilities. “The model combines precise layout data of the production facility with accurate information on all machines, equipment and furnishings that are located in the space represented by the virtual model. The 3D images of the objects can be computed from CAD data or on the basis of photographs of the machines, robots and production lines,” explains Yonit Doanis, IntoSite’s product manager at DF PL. The user can view the model from all sides or walk through the virtual space.In addition, all objects in the model can be tagged with supplementary information, such as written comments, videos or drawings.

Virtual application – real benefits

The software makes it possible for distributed teams of developers to share information and to work jointly on the same production site or simultaneously on different facilities. For example in the scope of a pilot project at Ford motor company. Together with the customer, the software experts of the Digital Factory (DF) Division used IntoSite to produce virtual representations of Ford production sites in the US. These models allow the users to compare the processes in the different Ford facilities and to optimize them across all sites – because all that’s needed to access a factory is a click of the mouse.

Just dive in!

The high performance level of the new Siemens software was demonstrated at the EMO 2015 conference, the leading European trade fair for the machine tool sector. Based on construction drawings and photographs using CAD software, IntoSite services were used to create a realistic 3D model of the Siemens booth. The virtual 3D model reproduces the original booth at the Fiera Milano halls down to the last detail: The screen shows not only machines and products, but also the tiniest details of the booth’s design, such as nameplates and legends. An especially amazing feature: Even the product videos and animated clips shown on the booth’s screens are included in the representation created by the innovative Siemens software.

Sounds exciting? Why not go for a first-hand impression of the capabilities of the IntoSite software? Enjoy a virtual trip to Milan and an exploratory tour of the Siemens booth as well as of a couple of Siemens Technology and Application centers (TAC).

Visit Siemens’Intosite web page to learn more.