Redefining collaboration with the Industrial Metaverse and the Tecnomatix portfolio

Explore two use cases that illustrate how Siemens leverages the Industrial Metaverse combined with the Tecnomatix portfolio, merging the digital twin with their real-world counterparts, helping companies streamline efficiencies and optimize production and processes.

Meet the authors

Principal Key Research Scientist

Siemens Technology

Head of Research Group

Siemens Technology

Director of Advanced Robotics Simulation Siemens Digital Industries Software

The evolution of the Industrial Metaverse

In today’s interconnected manufacturing landscape, the need for innovative approaches to collaboration has become increasingly evident among factories. Traditional methods of communication and coordination often prove inadequate. Traditional methods refer to the current mode of collaboration which heavily depends on file exchange-based discussions, leading to back-and-forth discussions and, sometimes, ambiguous communication. Think of simulated machines, factories, transport networks, and other complex systems, which require real-world problem solving in industry and manufacturing.

Most recently, a transformative concept that emerged from the realms of social and gaming domains has now found its place in the industrial sector: the metaverse. Initially developed to transform social experiences in the gaming world, the metaverse is also changing the way we collaborate within industrial value chains.

The Industrial Metaverse provides a centralized platform where multiple stakeholders can access and share their digital twin. By mirroring and simulating real machines, factories, and other complex systems in the digital world, it will empower industries, from automotive to health care, to solve extraordinarily complex real-world problems digitally.

The Industrial Metaverse will bring together the digital and real worlds. It will enable a constant exchange of information, data, and decisions and empower industries to solve extraordinarily complex real-world problems digitally, changing how organizations operate and unlocking significant societal benefits.”

Siemens MIT-Technology Review Insights Report

The Industrial Metaverse is a place to collaborate, experience and interact with the comprehensive digital twin and eliminates inefficiencies like cumbersome file exchange, allowing true real-time collaboration with streamlined communication. This ensures that all team members are working on the latest version, understand the impact on common goals, and reach a consensus more efficiently.

By harnessing the power of the physics-based digital twin in a virtual shared space, collaboration on the value chains can be significantly enhanced. The Industrial Metaverse enables seamless cross-organizational collaboration, real-time visualization and simulation, collaborative design and engineering, and provides a centralized ground truth for information. These benefits empower stakeholders to work together with heightened efficiency, driving productivity, fostering innovation, and ultimately achieving success throughout the industrial value chains.

In this blog, we illustrate two examples of how the Industrial Metaverse will advance the collaboration between factory plants and their equipment providers.

The Industrial Metaverse in action: use cases

Case one: Visual collaboration in production planning with interoperable digital twins

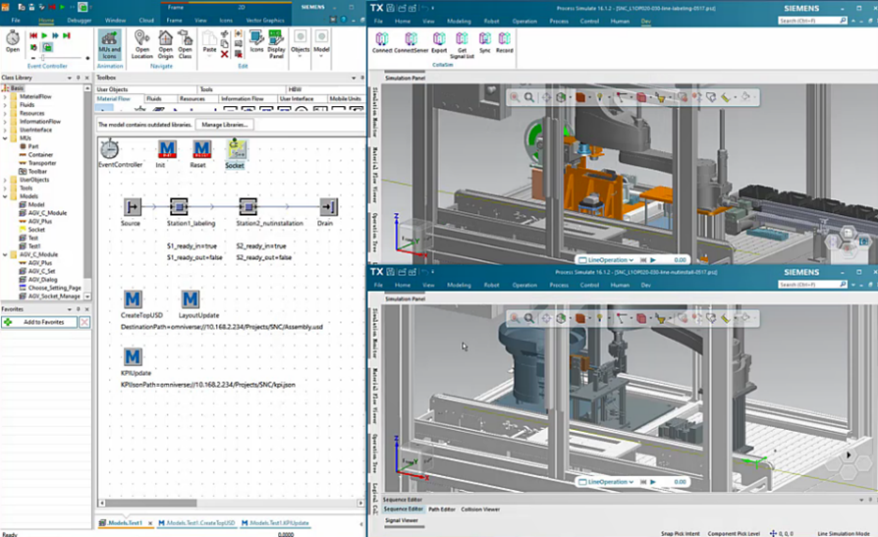

In this scenario, the factory aims to create a modular production line for a flexible electronic assembly. With the Industrial Metaverse, factory engineers can effortlessly showcase the factory environment to potential suppliers in an intuitive way, without disrupting normal operations. Both suppliers and factory engineers can develop their own digital twin models within their unique modeling environments. Suppliers can utilize Tecnomatix Process Simulate to create and edit the models for the labeling station and screwing station, while factory engineers can employ Tecnomatix Plant Simulation to build the material flow model, which coordinates the Process Simulate models. Once prepared, a collaborative review is initiated.

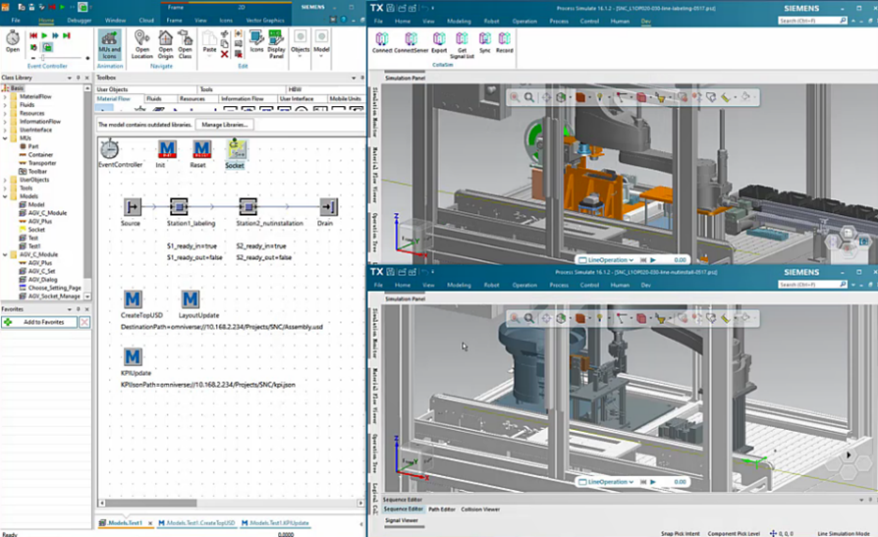

This is where the transformative power of the Industrial Metaverse comes into play. Each collaborator brings their individual models, which seamlessly interoperate within a unified 3D scene. Illustrated in Fig. 1, the Industrial Metaverse platform allows participants to make real-time adjustments to their specific models from their own computers, with the immediate impact on overall production visible to all involved. This level of transparency and synchronicity expedites the decision-making process, enabling collaborators to reach collective agreements rapidly and efficiently.

Fig. 1 depicts how the Tecnomatix Plant Simulation model of the modular production line, as well as two Process Simulate models of the two modular work stations are orchestrated by the Plant Simulation model. Fig 2/Fig 3. features the 3D visualization of the modular production line immersed in a factory scene provided by NVIDIA Omniverse.

Case two: Collaborative production validation by combining real and virtual

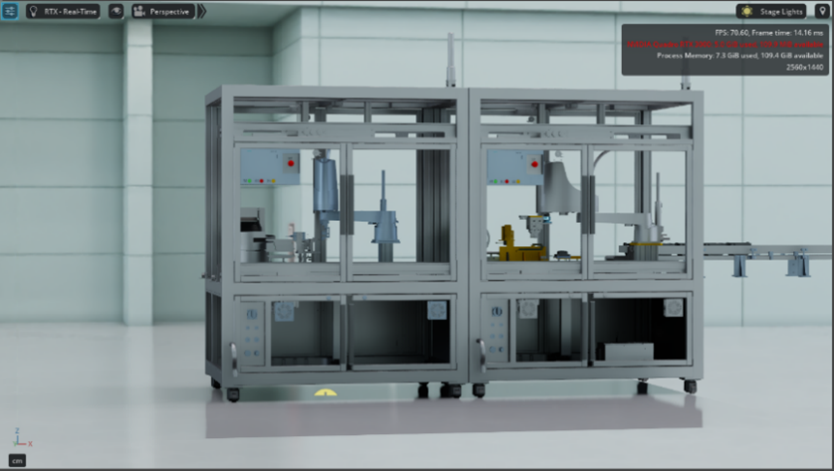

In this scenario, a machining workshop aims to enhance production efficiency by incorporating an Autonomous Mobile Robot (AMR) to transport workpieces from the warehouse to designated processing units. Even before shipping the AMR models to the workshop, the AMR supplier can virtually send their AMR models to the site. Using a pair of Augmented Reality (AR) glasses, the factory engineer can monitor the movement of AMR models overlaid upon the existing production line as if they are real. The AR glasses transmit the on-site scene to the AMR supplier, enabling both parties to share a mixed reality scene from a first-person perspective.

With the ability to adjust the behavior of the AMR models in Tecnomatix Process Simulate, the AMR vendor can make necessary adaptations based on the workshop’s specific requirements before shipment. These adjustments are promptly reflected in the AMR models displayed on the AR glasses. Furthermore, the AMR vendor can engage in live meetings with the factory engineer, facilitating collaborative testing and enabling joint completion of tasks.

The future of the Industrial Metaverse

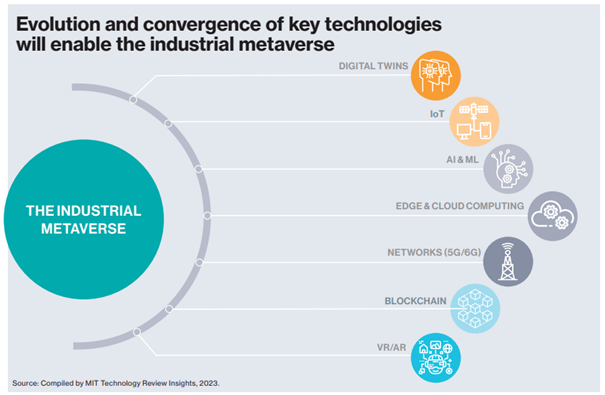

The Industrial Metaverse will emerge as the result of the further development and convergence of the digital twin and other technologies, such as IoT, AI and ML, blockchain and more as referenced in “The emergent industrial metaverse,” an MIT Technology Review Insights report sponsored by Siemens.

For example, the collaboration through the digital twin in the Industrial Metaverse opens opportunities to leverage the powerful dynamics of cloud technologies such as artificial intelligence (AI) and virtual reality (VR) in a wide range of use cases. Before the Industrial Metaverse existed, these advanced technologies were not easily as accessible. In other words, the Industrial Metaverse would help democratize the use of all these technologies to help engineers solve an array of engineering challenges in their daily lives.

By empowering collaboration through the digital twin, the Industrial Metaverse offers the potential to greatly accelerate the existing processes in plants, leading to substantial reductions in timelines by days, weeks or even months. These improvements will provide early adopters a competitive advantage by allowing to capitalize on fleeting market opportunities, boost productivity, and reduce both effort and costs.

As we embark on the era of digital transformation, embracing the Industrial Metaverse is a strategic move that can drive operational excellence, propel businesses towards sustained success in an ever-evolving marketplace and contribute to the overall success of stakeholders within the value chain.

![Immersive Engineering with Process Simulate Virtual Reality [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/06/siemens-process-simulate-collaborate-virtual-reality-solution-2-395x222.png)