Process Simulate Collaborate: Enhanced Efficiency in Robotics Simulation [VIDEO]

Exchanging feedback and design change requests to robotic simulation projects involves input from engineering, plant management, shop floor, sales, OEMs and suppliers. With this many cross-functional teams, it can become labor intensive and costly to centralize and optimize workflow efficiencies, causing delays and miscommunications in simulation projects.

Explore how Process Simulate Collaborate helps global teams leverage cloud-based simulation to virtually validate manufacturing concepts quicker. Users can generate shareable 3D visualizations and exchange frictionless feedback on factory production lines and robotic workcells like never before.

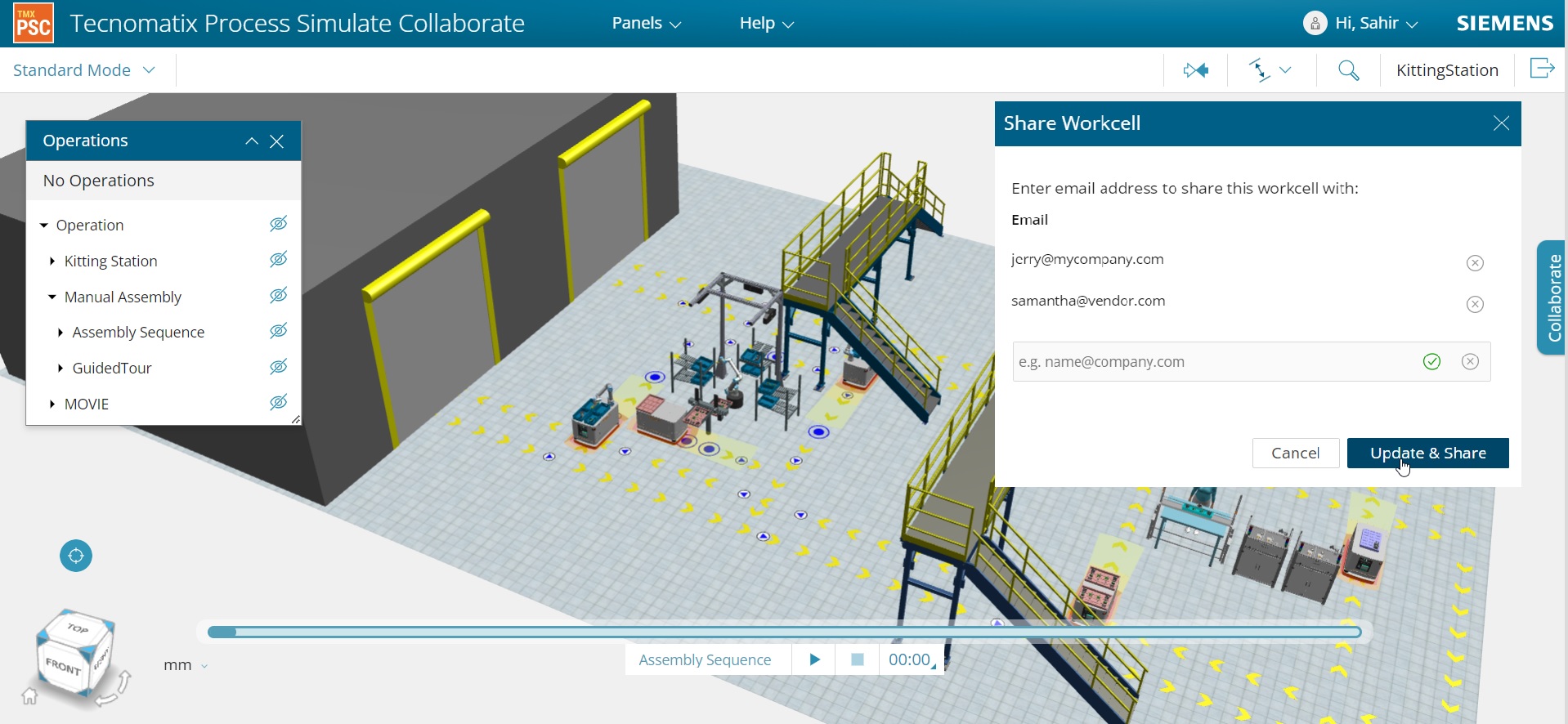

Process Simulate Collaborate stands out with its exceptional features and reduces rework and iterations of Process Simulate-authored studies by extending the digital twin version of the factory production lines into the cloud. Now engineers, OEMs or suppliers can better manage and collaborate on studies with cloud-based simulation, without needing to invest in expensive software or hardware.

Upload, collaborate and share with ease

For a Process Simulate engineer, the cloud-collaboration journey begins with the transfer of the Process Simulate study on a user’s local desktop and opening Process Simulate Collaborate in the cloud. With just a single click within Process Simulate, the line designer or simulation engineer uploads the study, making it easily accessible for other internal and external stakeholders. This step unlocks the power of promoting collaboration and knowledge exchange by synchronously editing a shared design.

Seamless feedback integration

Process Simulate Collaborate enables reviewers to showcase design changes in real time, ensuring that everyone – including the engineer, suppliers and OEMs, are aligned. When a design change request emerges, the line simulation engineer takes the initiative to include a note, taking into consideration its priority level (low, medium, or high) and the specific type of note (general, safety, collision, or ergonomic).

With cloud-based simulation, generate shareable 3D visualizations and exchange frictionless feedback on factory production lines and robotic workcells. Explore how Process Simulate Collaborate helps to empower engineers, OEMs, suppliers, system integrators, line builders and sales managers to unify 3D simulation and accelerate projects by synchronously editing a shared design.