Material flow simulation for the medium-sized manufacturer

Medium-sized companies can benefit from digital manufacturing technologies for material flow and logistics analysis to address the requirements of product variance and manufacturing system complexity.

—–

This is the third in a series of blogs where we discuss the value of line planning in industry today and the potential benefits that can be realized by medium-sized companies utilizing digital manufacturing solutions for this purpose.

—–

Following up on our second blog post for layout planning challenges, we remain focused on:

- Market uncertainties

- Ongoing improvement initiatives

- Rapidly growing portfolios

- Increasing system complexity

- Cost

- Visualization

In this post we address the material flow and logistics challenges that you face when implementing new production systems or changes to existing systems.

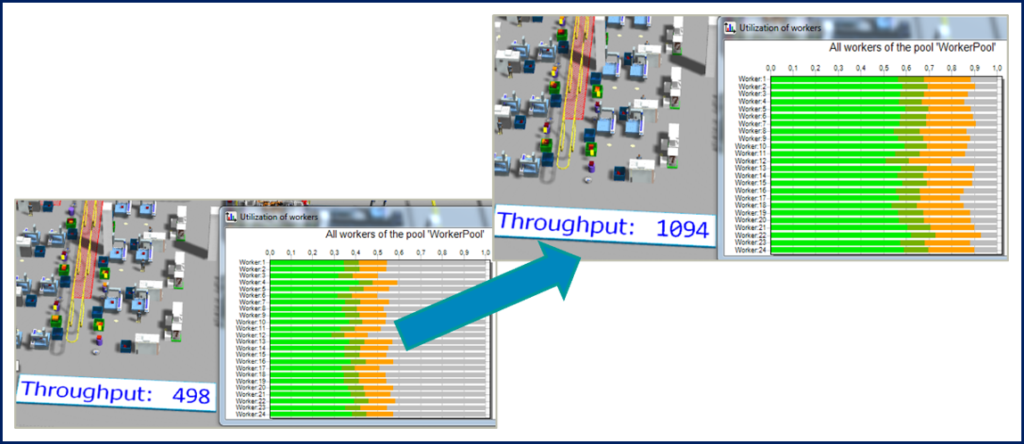

When handling high product variance and manufacturing system complexity, under pressure from different locations, you must be able to:

- Detect and eliminate problems that otherwise would have required costly and time-consuming correction measures during production ramp-up

- Minimize the investment cost for production lines without jeopardizing the required output

- Optimize the performance of existing production systems by implementing measures that have been verified in a simulation study, prior to implementation of the real system

Once everything is in place, as always, you need to present any proposed changes or new investments to the different stake holders involved, e.g. management, customers, etc.

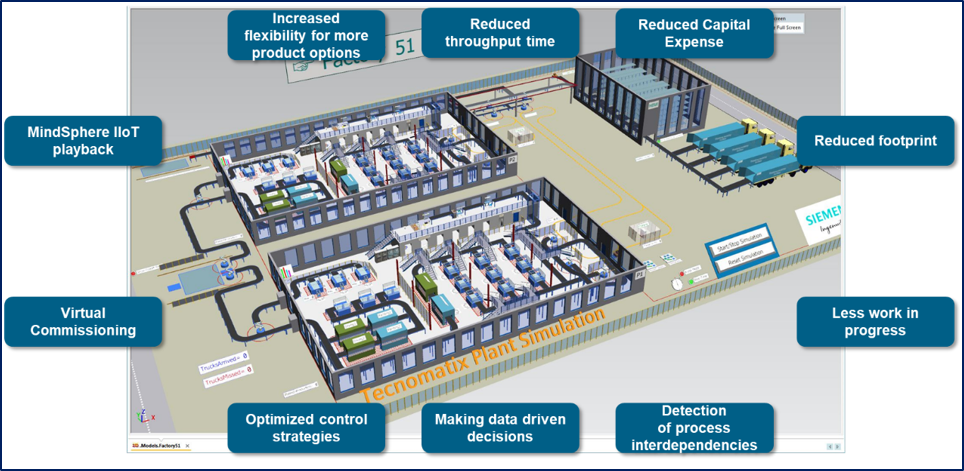

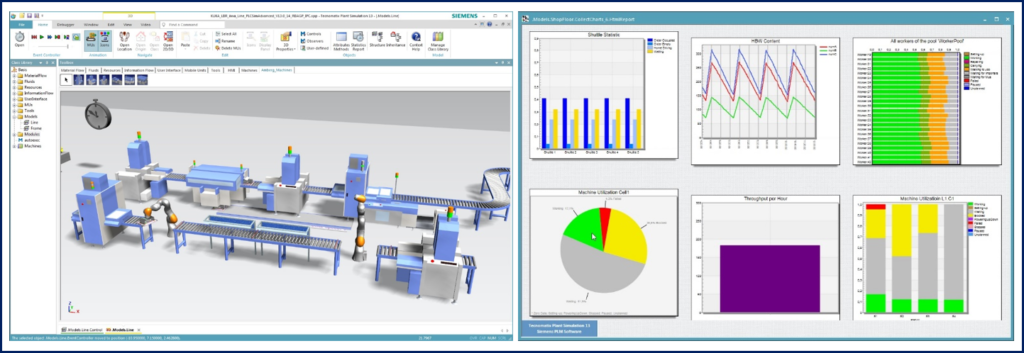

For all of this, you can use Tecnomatix Plant Simulation. Plant Simulation is a discrete-event simulation software used for studies and experiments of material flow, throughput, operations, staffing and logistics in any type of production environment. Plant Simulation is successfully used and applicable in nearly all industries.

Key capabilities of Plant Simulation provide you with tools for:

- Material flow and throughput validation

- Testing of production control and layout alternatives

- Optimization of material handling and logistics

- Charting and display of production KPIs like utilization, performance, etc.

- Dimensioning of capacities for machines, buffers, AGVs/AMRs, etc.

Is Plant simulation just for experts? Certainly not.

A world-wide network of service providers and an active community are there to support and assist you with your successful production system modeling and simulation efforts.

In summary, when you are faced with challenges to determine material and resource requirements, plan logistics chains, analyze utilization, identify bottlenecks and plan for your production mix you can use material flow simulation. Tecnomatix Plant Simulation helps you make investment decisions with confidence, increase margins, minimized tied-up capital and, reduce lead times and energy costs.

—–

> Learn more about Plant Simulation

> Try Plant Simulation for free

> Get started with Plant Simulation

> Find your local partner using the Siemens partner finder

> Buy Plant Simulation online

Contributors: Moshe Schwimmer, Noam Ribon