Products

Lab quality motion capture a reality

Xsens, a leading innovator in professional 3D motion tracking technology based in Netherlands, recently announced a new update in its integration with ergonomics analysis Jack software and the Process Simulate solution in the Tecnomatix portfolio.

The updated integration between Xsens and Siemens PLM Software’s Human Simulation software will enable even more flexible motion capture and world-class data collection outside of the lab.

The updated integration between Xsens and Siemens PLM Software’s Human Simulation software will enable even more flexible motion capture and world-class data collection outside of the lab.

Integration enhancements

The new update sees numerous feature enhancements across both the Xsens and Siemens PLM Software portfolios, strengthening the overall power of these combined technologies:

Enhanced scaling model

The ability to precisely match the Jack or Jill avatars to the human subject tracked with the Xsens application has been augmented. This improved anthropometric match between the human model and the subject being analyzed means a significant improvement in tracking accuracy and therefore deeper, more true-to-life research results.

Improved tracking accuracy

Greatly improved tracking accuracy in the Xsens software makes for more portable and flexible in-field data acquisition than ever before.

A new way to review and edit data

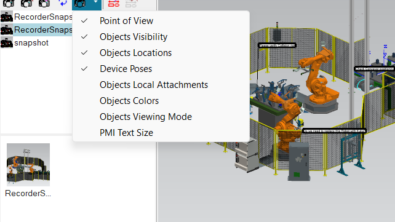

Tecnomatix enhancements include the ability to read motion capture data directly into the simulation environment, enabling users to easily review and edit the captured data, and use it to quickly build full simulations for further analysis.