Assembly Line Planner in NX 1980 – What’s new?

Assembly Line Planner is a process planning application based on Siemens NX™ software. It enables you to plan a complex production line with a focus on the different technologies and manufacturing features used to create an assembly, such as spot welds, weld studs, rivets, continuous joints for fastening and sealing, and more. In this blog, gain an in-depth look into the new capabilities of Assembly Line Planner in NX 1980.

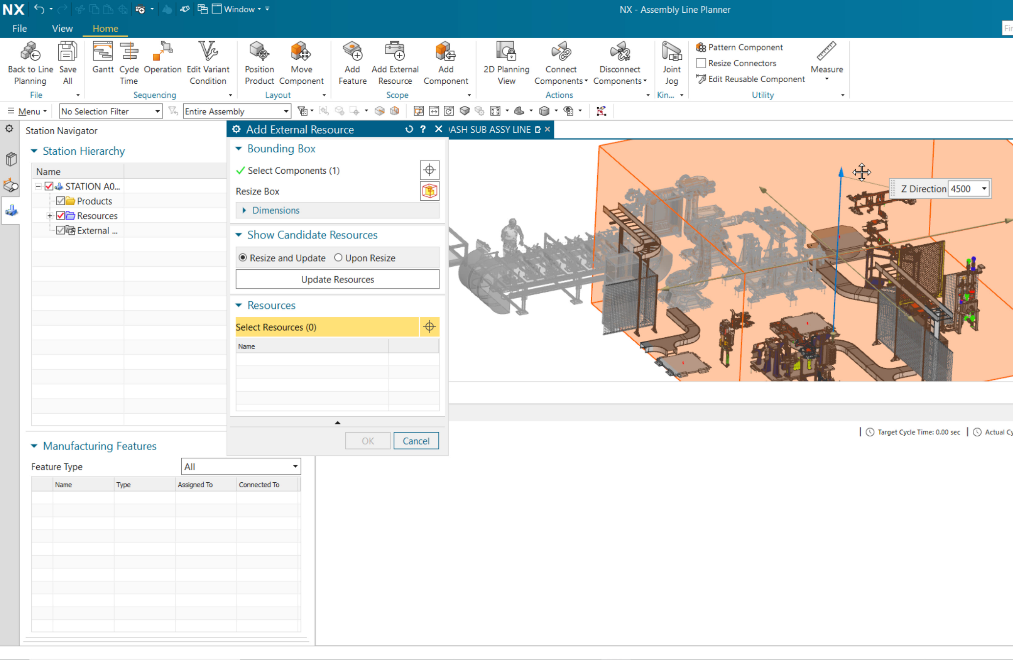

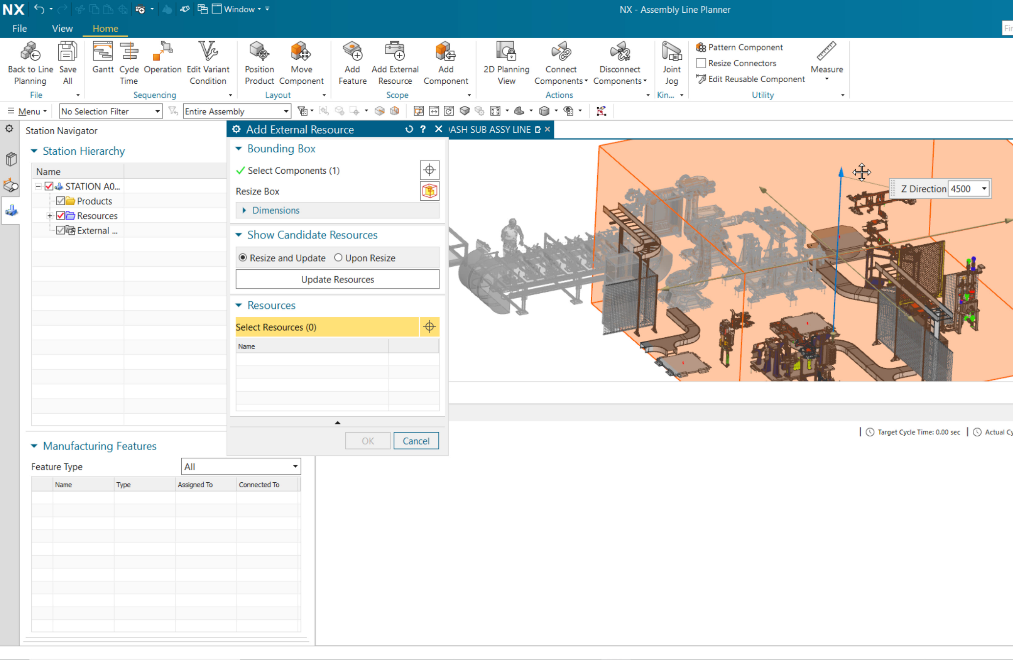

Plan a process with resources external to the station

A common use case when planning the process inside of several stations is to use the same resource in 2 or more different stations. An example for this could be a conveyor or a robot moving a certain part from one station to another. The robot belongs to one station in the bill of equipment (BOE) but is relevant for the process of another station where it delivers the part.

The external resource function in Assembly Line Planner is now allowing a full support for this workflow. After searching for nearby resources, a user can add them to the process planning scope of the desired station and assign it to operations. The integrity of the BOE is maintained, and the resource is not duplicated during this process.

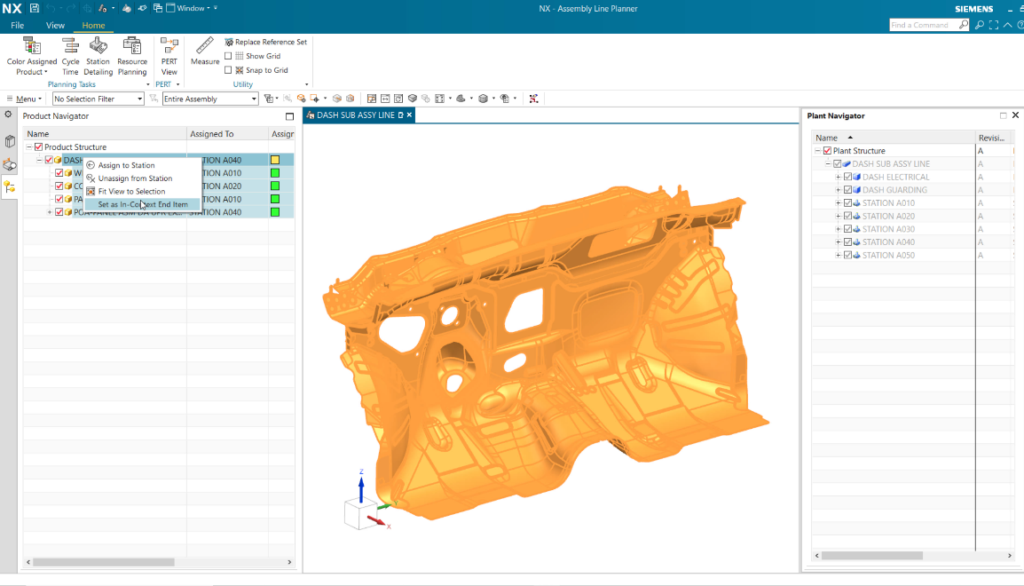

Define In-Context End Items in the context of the line

Assembly Line Planner reads End Items from the product structure and adapts the feature search and assignment logic to them accordingly. This means that features like weld points positioned inside of an End Item are not displayed, as they would already be welded when planning the End Item on the line.

In addition to this behavior, ALP now supports defining End Items in the context of the loaded line directly in the NX session. This allows a user to remove additional assemblies from the feature search results and support use cases where an assembly needs to be considered as an End Item in the line, although it is not an End Item in the product structure. An example of this is if the assembly is manufactured in another line that is not currently loaded and the features assigned have already been processed.

This information is stored directly in the process data and does not require write access to the product structure, therefore maintaining its integrity at all times.

Learn more

For more information on the new capabilities in NX 1980, check out these resources: