How Philippines bike maker Rurok Industries is beating the competition through innovation

Sometimes, something imperfect can lead to something perfect: For P.J. Tolentino it all started with a bike that did not perform well in the Philippine mountains. Tolentino started to think of how to improve the bike, which led him to create his own startup business: Rurok Industries. His goal since then is to show the world that with the help of advanced product development tools, like Solid Edge, Rurok can provide high-performance bikes locally while beating competitors by innovation globally.

“Bikes should move forward, progress and get better, just as the rider does,” says P.J. Tolentino, the founder and head engineer at Rurok Industries. As the performance bike industry is a highly competitive market, Rurok Industries wanted to distinguish itself from the competition through innovation, leveraging rider experience and feedback and using cutting-edge technology and tools. “We believe that a local Filipino company can be globally competitive through innovation,” Tolentino says.

Moving from trial & error prototyping to a more digital approach with Solid Edge

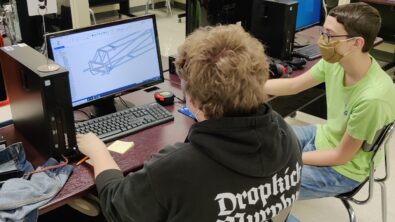

Developing high-end, precision-engineered products is challenging, especially for new products. Innovative bike design requires a comprehensive testing and prototyping process. Tolentino outlines some of the challenges the company faced when starting out. “Creating physical prototypes is very costly and time-consuming. We had to thoroughly test our designs before we went into production. We were always working on uncharted waters and 99 percent of the time our early prototypes didn’t work very well.” Frustrated with traditional parametric modeling software and its limitations, Rurok Industries decided to adopt Siemens Solid Edge® software for computer-aided design (CAD).

Using Solid Edge, Rurok Industries has been able to streamline its prototyping process, greatly reducing engineering costs and vastly improving its success rate for the prototyping of parts. As a result, they have been able to reduce their development time for parts by 20 percent and produce parts that are 50 percent stiffer and 20 percent lighter. Reduced costs allow Rurok Industries to grow and expand its product offerings and to reallocate resources to other aspects of the business.

Intuitive design thinking with Synchronous Technology

“When we were using a purely parametric modeling software, shaping parts meant a lot of punching in numbers,” Tolentino explains. “Often times, the shape that we had in our head does not look like the final design, mostly because we were constrained to design in fixed shapes and numbers. Synchronous technology of Solid Edge was a more expressive way to shape and design our parts. Instead of drawing shapes and punching numbers, we now sketch out shapes with a digital pen, and the synchronous technology sculpts the shape. We are able to push, pull and bend the design instead of punching in numbers.”

The design workflow is more streamlined, and Rurok Industries can now transform design ideas into manufactured parts with ease.

Generative Design for optimal balance between material, weight and strength

One capability of Solid Edge that has been indispensable for Rurok Industries is generative design, which can optimize complex shapes to balance weight and strength and minimize manufacturing material waste. It has allowed Rurok Industries to produce optimized parts more efficiently.

“Before using Solid Edge, we used finite element analysis simulations to look at which areas of the parts are less stressed, then figure out the shape that would remove those parts. There is a lot of estimation being done with this approach, and the final design is far from perfect. Using Solid Edge, this is a much easier and quicker process. And it’s a much more optimized design, which we couldn’t have achieved with our old designs where everything was done manually,” summarizes Tolentino.

In the future, Rurok will continue to drive innovation to further develop its performance mountain bikes. In 2019, they offered three different models of mountain bikes to the international market: the Cordillera, the Kanalaon and most recently, the Halcon – each one made for the specific challenges of different landscapes and biker preferences. The company’s goals are simple yet progressive – keep making better bikes and keep riding.

To learn more about the Solid Edge for Startups program, visit our site.

Comments