What’s new in Simcenter systems simulation 2410

Welcome to the latest release of Simcenter systems simulation 2410! This update is packed with exciting new features designed to enhance your simulation capabilities and streamline your workflows. Let’s explore these innovations and see how they can transform your projects.

Platform

As systems simulation grows in complexity, models are becoming larger and more complex, demanding more computational power. In response, the Simcenter Amesim solver has been optimized to be faster, resulting in significant time savings for almost all models used in our test procedures, up to more than twice as fast for 18% of the models evaluated. This improvement allows users to handle larger models with ease, boosting productivity and enabling quicker decision-making, which is essential in today’s fast-paced engineering environment.

Thermo-fluid simulation engineers will appreciate the new PCF (Piping Component File ) import feature, which allows for the direct import of PCF files into Simcenter Amesim 2410, automatically generating the system simulation model. This seamless integration eliminates error-prone manual steps, enabling users to focus more on analyzing results rather than setting up models. This is particularly beneficial in industries like aerospace, marine, and energy, where precision and efficiency are paramount.

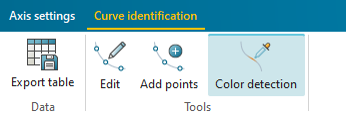

For those working with part specification curves in printed images and using the graph digitizer released in Simcenter Amesim 2404, the new color detection feature is a game-changer. It allows engineers to extract numerical values by detecting the color of the drawing within a restricted area, retrieving and exporting curve data as a table. This capability enhances the accuracy and reliability of simulations across all industries, especially when full characterization data is not readily available.

In Client for Git, the enhanced attribute definition offers a user interface that allows system and simulation engineers with administrator permission to define new attributes and enumerations without the need to edit CSV files and restart the server. This simplifies the process of attribute definition significantly.

The model comparison and three-way merge capability in Simcenter Client for Git offers robust comparison and conflict resolution for Simcenter Amesim 2410 models. This enhancement is particularly useful for engineers who version their models, simplifying the process of identifying differences and resolving conflicts.

Electrification

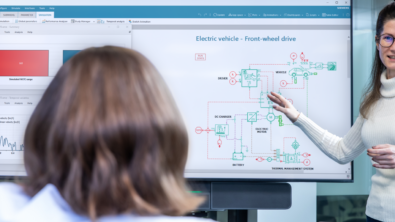

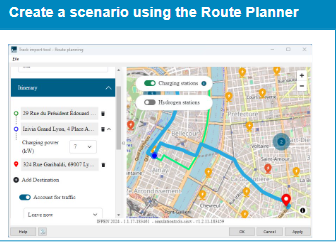

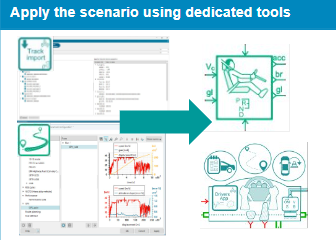

Optimizing the performance of electric vehicles (EVs) remains a top priority for automotive manufacturers. The new EV driving mission planning feature in Simcenter Amesim 2410 helps compute driving mission plans based on driver profiles and charging station stops, considering charging power and battery thermal management. This tool is essential for automotive and battery OEMs looking to maximize efficiency and protect components during real-world driving missions.

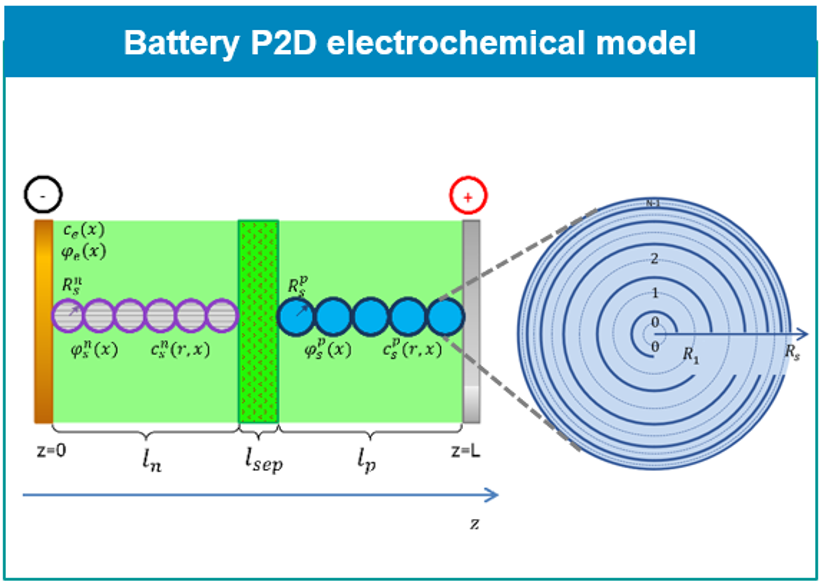

Battery technology also sees a significant improvement with the enhanced battery P2D electrochemical model with aging modeling. This feature addresses the critical issue of battery aging by modeling lithium plating and solid electrolyte interface (SEI) layer growth, allowing for accurate estimation of capacity loss over time. This is invaluable for automotive and battery OEMs aiming to enhance battery performance and longevity.

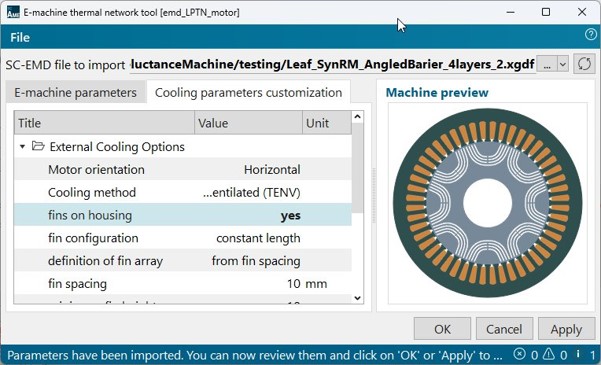

E-machine designers and OEM integrators will benefit from the new e-machine thermal network tool, which enables detailed customization of e-machine cooling settings directly from the application. Users can configure cooling systems using air, spray, and water-cooling options, including a fins model for air cooling. This tool supports the import of Simcenter E-Machine Design templates for Interior Permanent Magnet Machines (IPMSM) and synchronous reluctance machines (SRM) with constant airgap, ensuring efficient and reliable operation of electric machines under realistic and complex mission scenarios.

Thermo-fluid applications

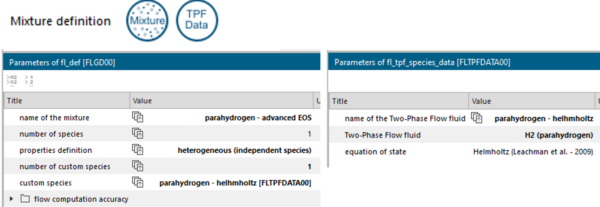

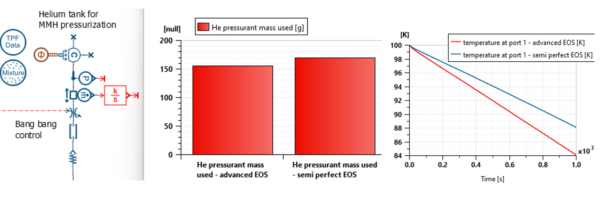

Thermo-fluid engineers working on complex systems involving gases at high pressures and low temperatures will find the new advanced equations of state for real gases in Simcenter Amesim 2410 particularly useful. With access to a broader set of equations, such as MBWR and Helmholtz, engineers can now predict system performance with greater accuracy, leading to significant improvements in efficiency and safety.

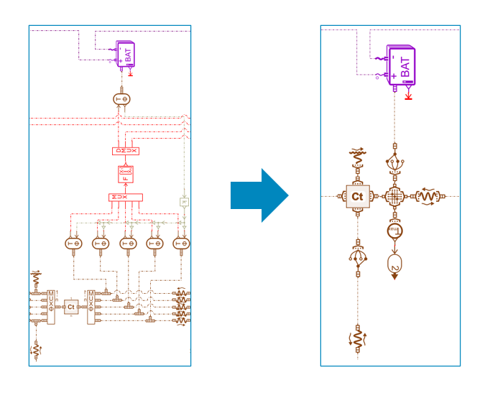

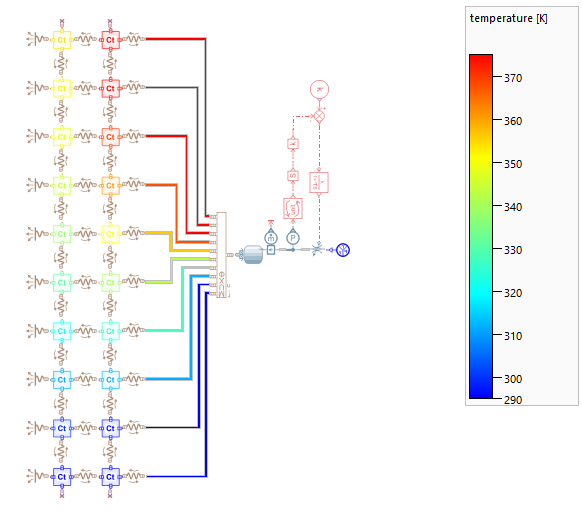

The new thermal vectorial components are designed to accelerate the modeling of thermal systems by enabling the tracking of thermal gradients more efficiently. For thermal engineers in the automotive, aerospace, building, and electronics industries, this capability is a game-changer. It allows users to easily evaluate thermal gradients and to modulate model fidelity to optimize response time. This means that complex sketches for discretized thermal modeling can now be replaced with models that are light, easy-to-read, and easy-to-set. Additionally, the ability to change discretization without altering the sketch simplifies the modeling process. The rooter component further enhances this by distributing a single heat flux to several thermal capacities, managing ratios and combining multiple temperatures into one. This capability is extensively used in designing battery direct cooling systems and accelerates the creation and usage of these models.

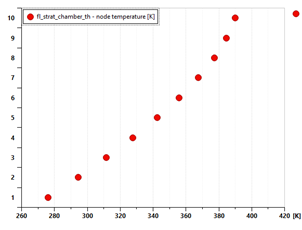

As we move towards more sustainable energy solutions, the need for efficient gas storage systems becomes increasingly important. The new thermally stratified gas tanks model in Simcenter Amesim 2410 allows for the assessment of temperature stratification along the vertical axis of gas storage tanks. This capability helps optimize the design and performance of gas storage tanks, ensuring they operate efficiently under various conditions.

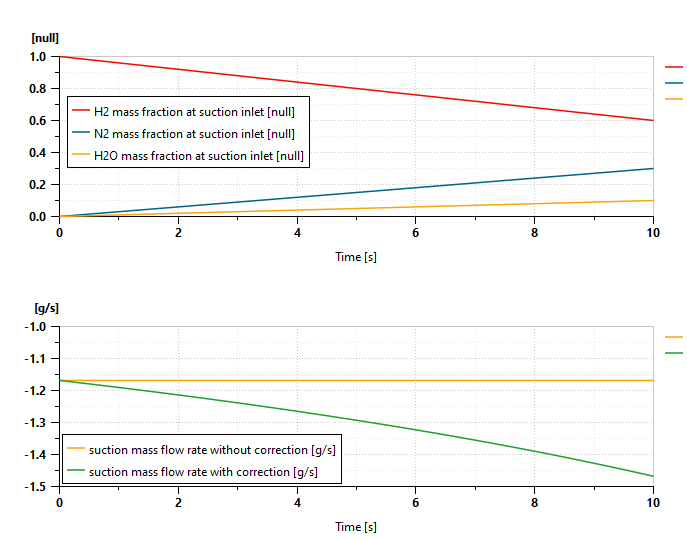

Thanks to the new advanced equations of state, you can now accurately model several components and phenomena such as ejectors, which play a vital role in systems like HVAC and fuel cells. The new ejector model in Simcenter Amesim 2410 introduces a functional ejector component with correction factors, allowing for a more accurate simulation of ejector performance using standard fluids like air and applying them to different gas mixtures.

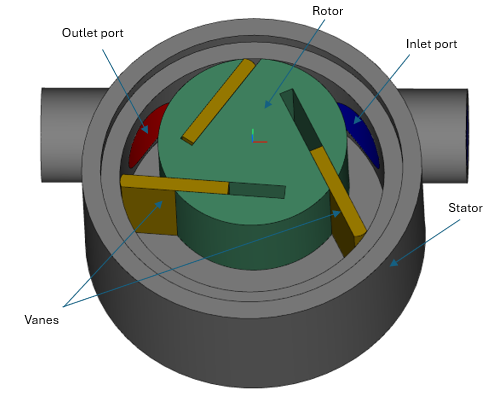

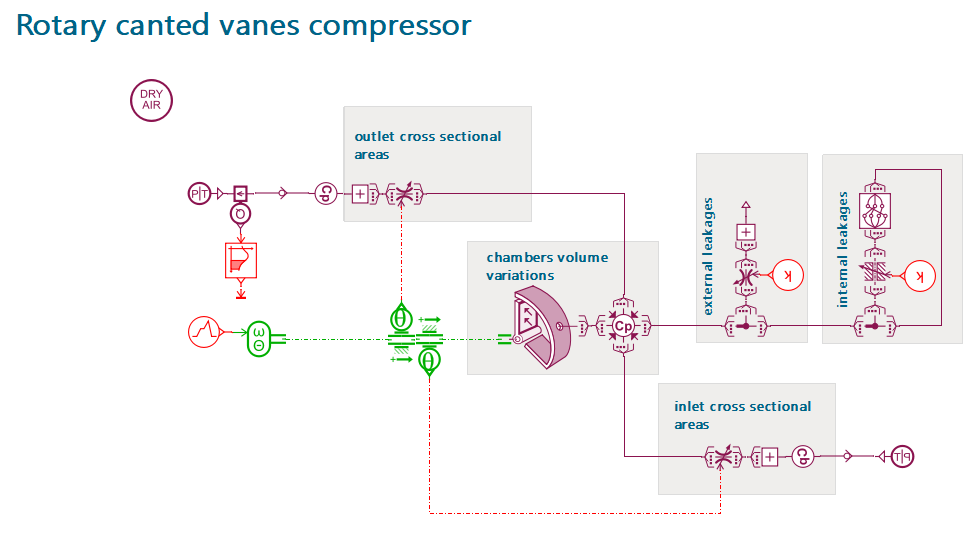

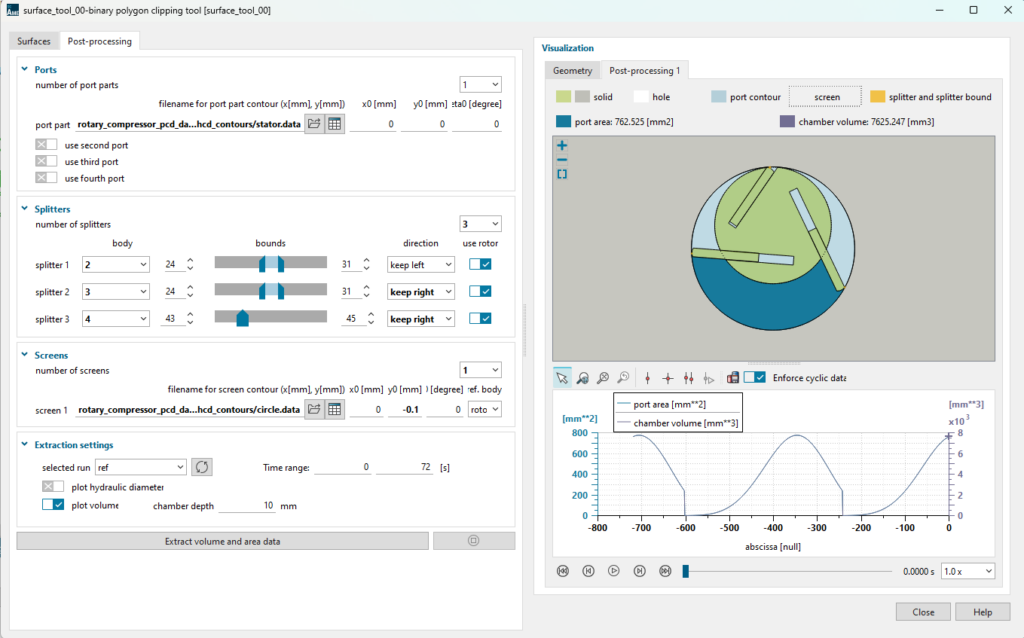

Compressors are vital components in many industrial processes. The new rotary vane compressor demo in Simcenter Amesim 2410 provides a comprehensive workflow to create a vane compressor model using standard PCD (Pneumatic Component Design) vectorial components. This demo shows a streamlined workflow to model complex compressor designs, allowing users to create systems from CAD files and explore characteristics like internal pressure ripple.

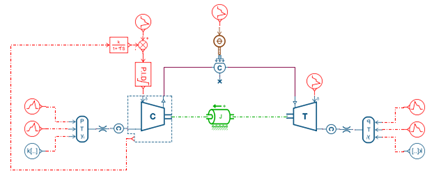

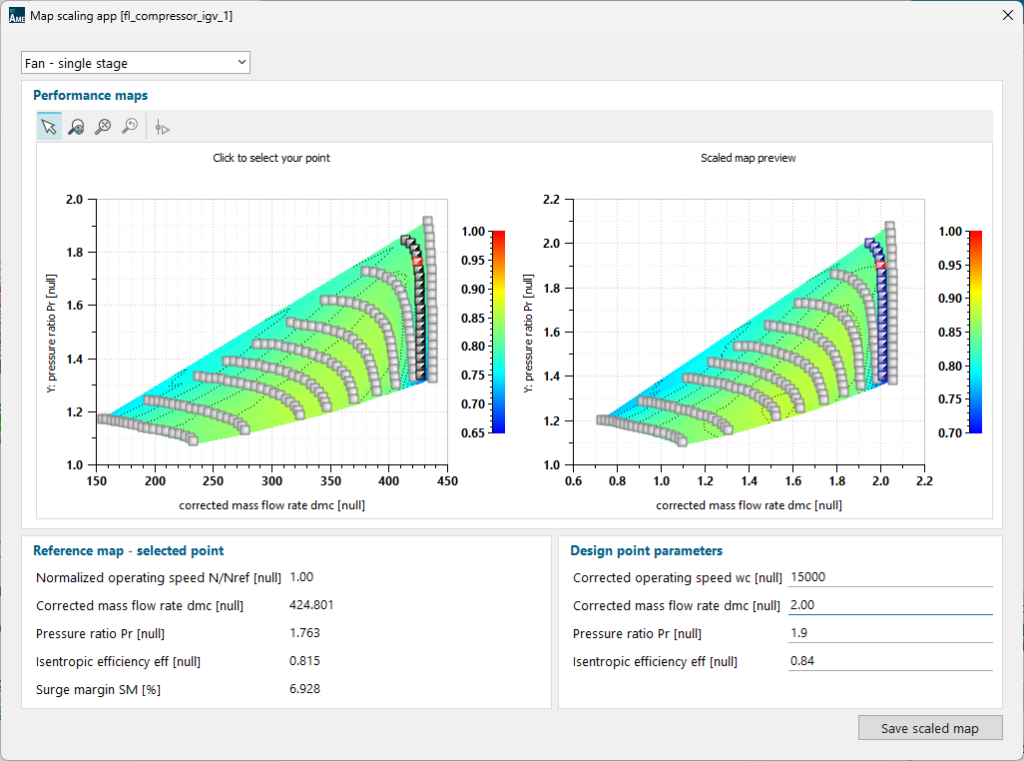

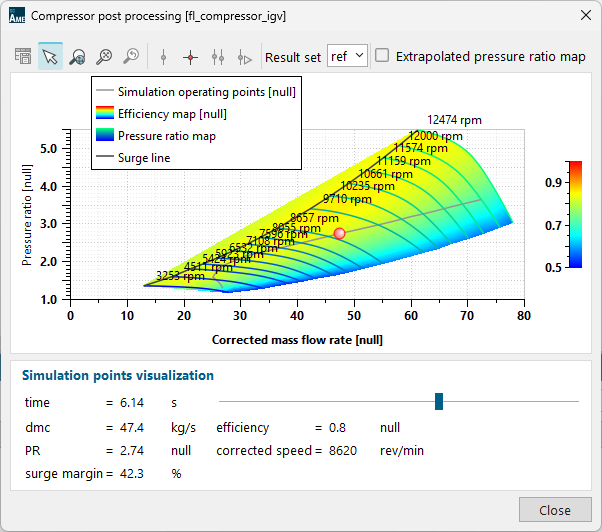

Engineers working with compressors and turbines often face challenges when performance maps are not readily available. The new SAE-based compressors and turbines feature in Simcenter Amesim 2410 addresses this issue by allowing for the modeling of fixed and variable-geometry compressors and turbines even with limited data. This flexibility is essential in the rapidly evolving turbomachinery industry.

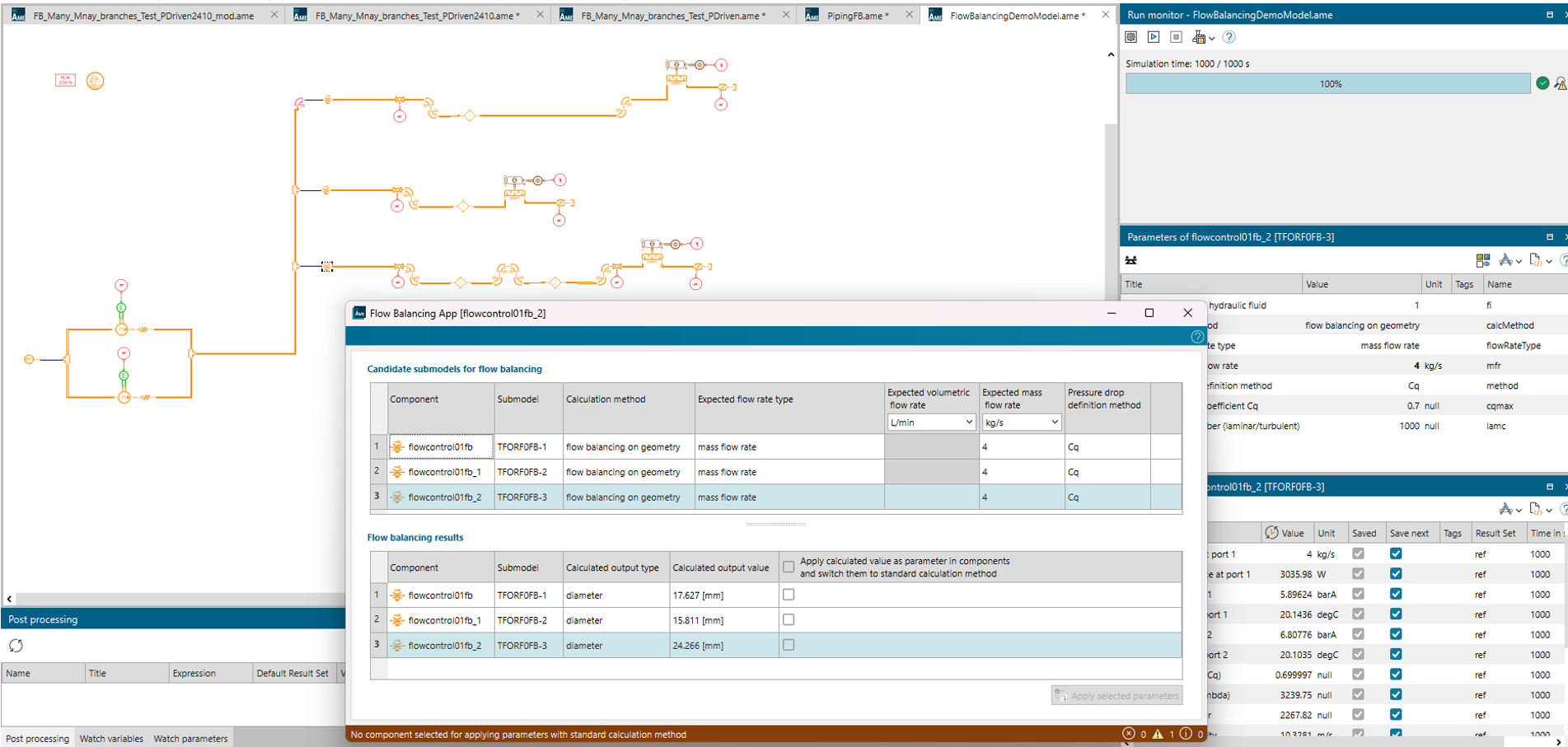

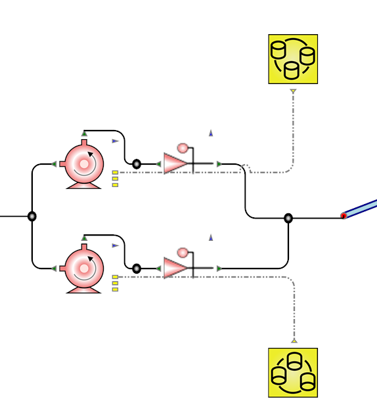

The new flow balancing capability in Simcenter Amesim allows users to size components quickly and balance flows within the system. This feature is particularly beneficial for system simulation users in the aerospace, marine, process, and energy industries, eliminating the need for costly optimization or complex control.

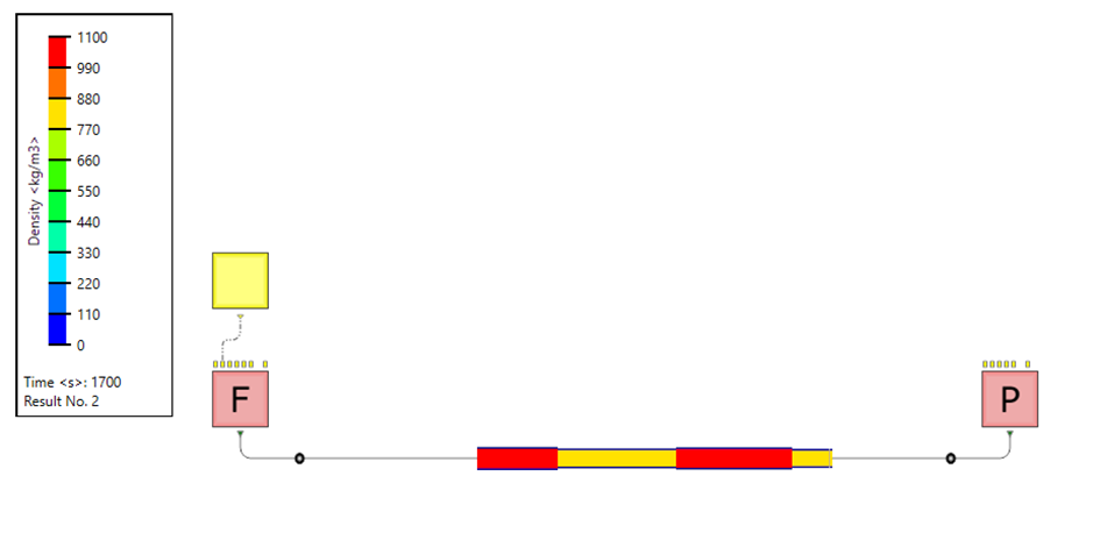

In Simcenter Flomaster 2410, the new batching pipe allows users to model the batching of products within piping systems more efficiently. This is particularly beneficial for pipeline engineers in the energy, utilities, and oil and gas sectors, enabling them to simulate pipeline operations more effectively and make informed decisions about product delivery.

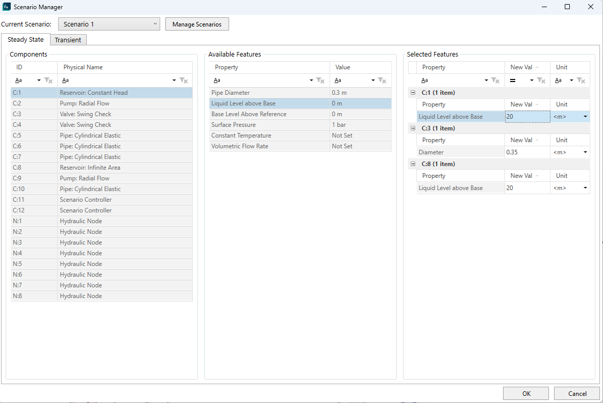

The new scenario manager & controller in Simcenter Flomaster 2410 are beneficial for fluid system design and operations engineers who need to investigate different operational schemes. This new capability enables engineers to save scenarios for future reuse, making it easier to adapt to system changes. By defining data for specific operational configurations in a single interface, engineers can set and check data more efficiently. The scenario controller also allows for complex control changes to be set and saved for replay, providing a robust tool for managing fluid systems.

The new custom catalogue view in Simcenter Flomaster 2410 enhances the user experience by allowing users to customize the catalogues they see upon logging in. This feature is particularly useful for systems simulation engineers who are new to Simcenter Flomaster 2410 or those focusing on specific systems, improving efficiency and aiding in training new users.

Conclusion

These features are set to further enhance your simulation experience, making it more efficient and accurate. Stay tuned for more updates and detailed tutorials on how to leverage these new capabilities in your projects. Happy simulating! 🚀

Feel free to share your thoughts or questions in the comments below. Let’s keep the conversation going!