Software architecture as automotive assembly line

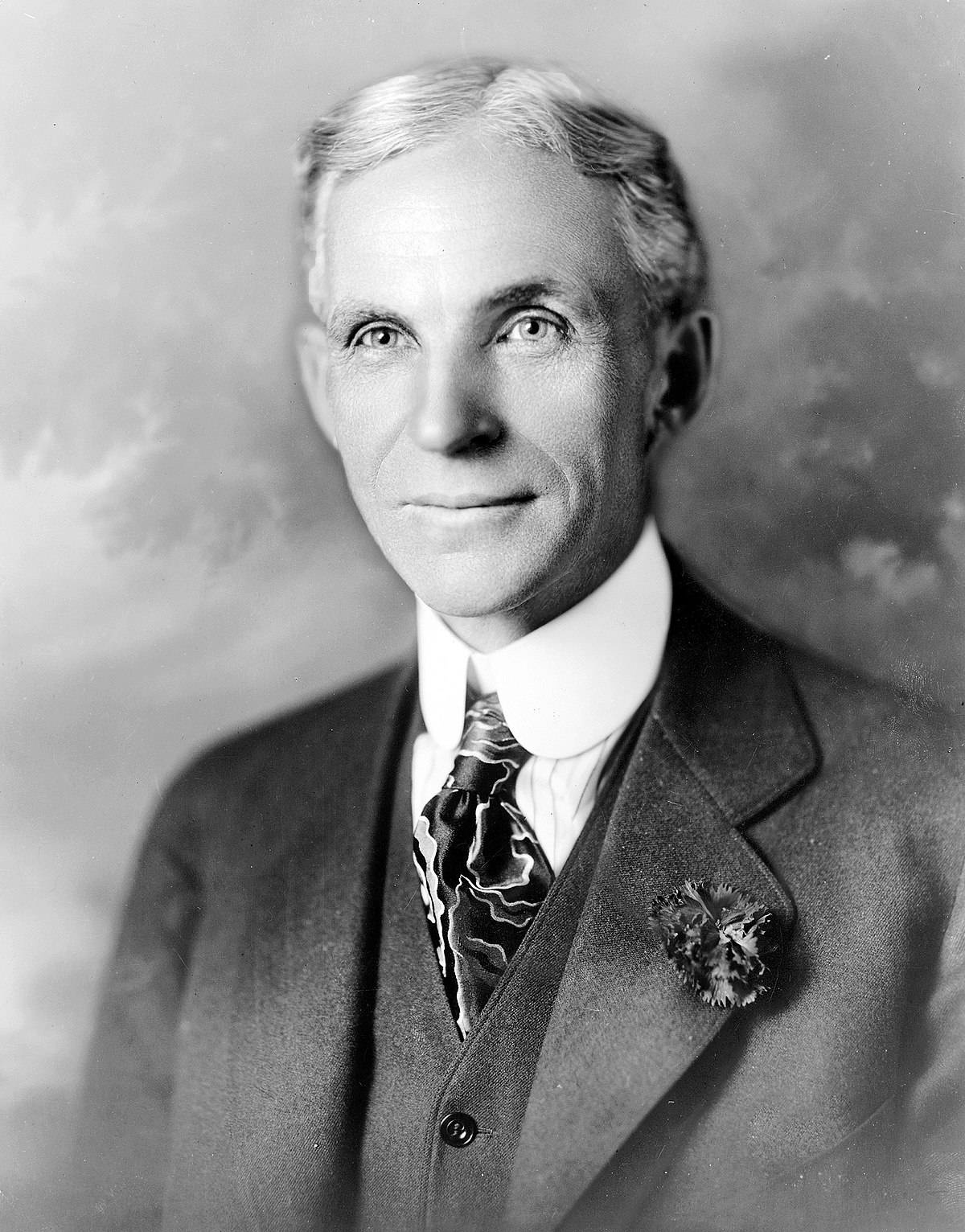

“If you always do what you’ve always done, you’ll always get what you’ve always got” – Henry Ford said that.

“If you always do what you’ve always done, you’ll always get what you’ve always got” – Henry Ford said that.

That was quite the assembly line did for manufacturing industry. The effect of assembly line was such that the businesses that did not adopt the practice soon became extinct. Now if you look at the main principle that Henry Ford brought with his modern day assembly line approach was to create a common platform with plug and play approach. The development time of a Model T reduced drastically from 12.5 hours to 93 minutes and saw a consumer cost reduction from $850 to $260.

Fast forward 100 years and we are in 21st century where a luxury car can easily be described as the digital transformation of their older self which runs ‘simply’ on code. A typical high-end car these days contains 100s of millions of lines of code, 100s of electronics control units (ECUs), 1000s of software controlled functions including many safety-critical functions.

Moreover, the short product and innovation cycles in the software and electronics industry plays a tremendous amount of time and cost pressure on software-intensive product manufacturers. They are expected to deliver high quality software for creating new products – fast engineering is required, as are the fault-free robust software.

Siemens PLM Software offers perfectly coordinated solutions for a holistic software development: software architecture used as central platform to efficiently support the entire value chain for embedded software development and using contracts for software test and validation.

Got curious about it?

We’re holding a live webinar on June 20 to address the challenges and solutions to facilitate collaborative controls and embedded software development using an integrated simulation toolchain. Feel fre to join!