Simcenter Culgi 2405 released! What’s new?

Many industries are facing increasingly stricter regulations for more sustainable and safer products. Especially in highly competitive industries, like e.g. the battery manufacturing industry, with tightening regulations and rapid time-to-market requirements. Companies must expand traditional engineering considerations for their product design to the selection or even the tailored design of novel materials. Gaining detailed insights into the underlying chemistry of your product and how and why the materials involved interact in certain ways and determine product performance at larger scales not just offer huge potential but become a true necessity.

To cope with this challenging engineering task, the tool of choice is Computational Chemistry. Computational Chemistry enables you to not only develop and screen novel materials but also bridge the gap between atomistic and molecular materials analysis and large-scale simulations like Finite element method (FEM), Computational Fluid Dynamics (CFD), or even system and process simulations.

With the new release of Simcenter Culgi 2405, we are once more adding a bunch of new capabilities that enable you to model the complexity of chemical systems and explore the possibilities of innovative material design, bringing safer, more sustainable, and higher performing products to market, faster.

Learn how to use Support Center

New enhancements in Simcenter Culgi are aimed at helping you:

Model the complexity

Improve simulation accuracy of charged systems

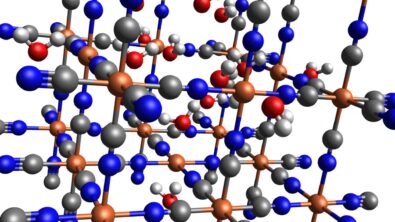

All simulations at the atomistic level require the proper calculation of atom charges. These atom charges are necessary to understand how electrons are distributed over the molecules, thus giving an indication of site of higher interaction, polarity, etc.

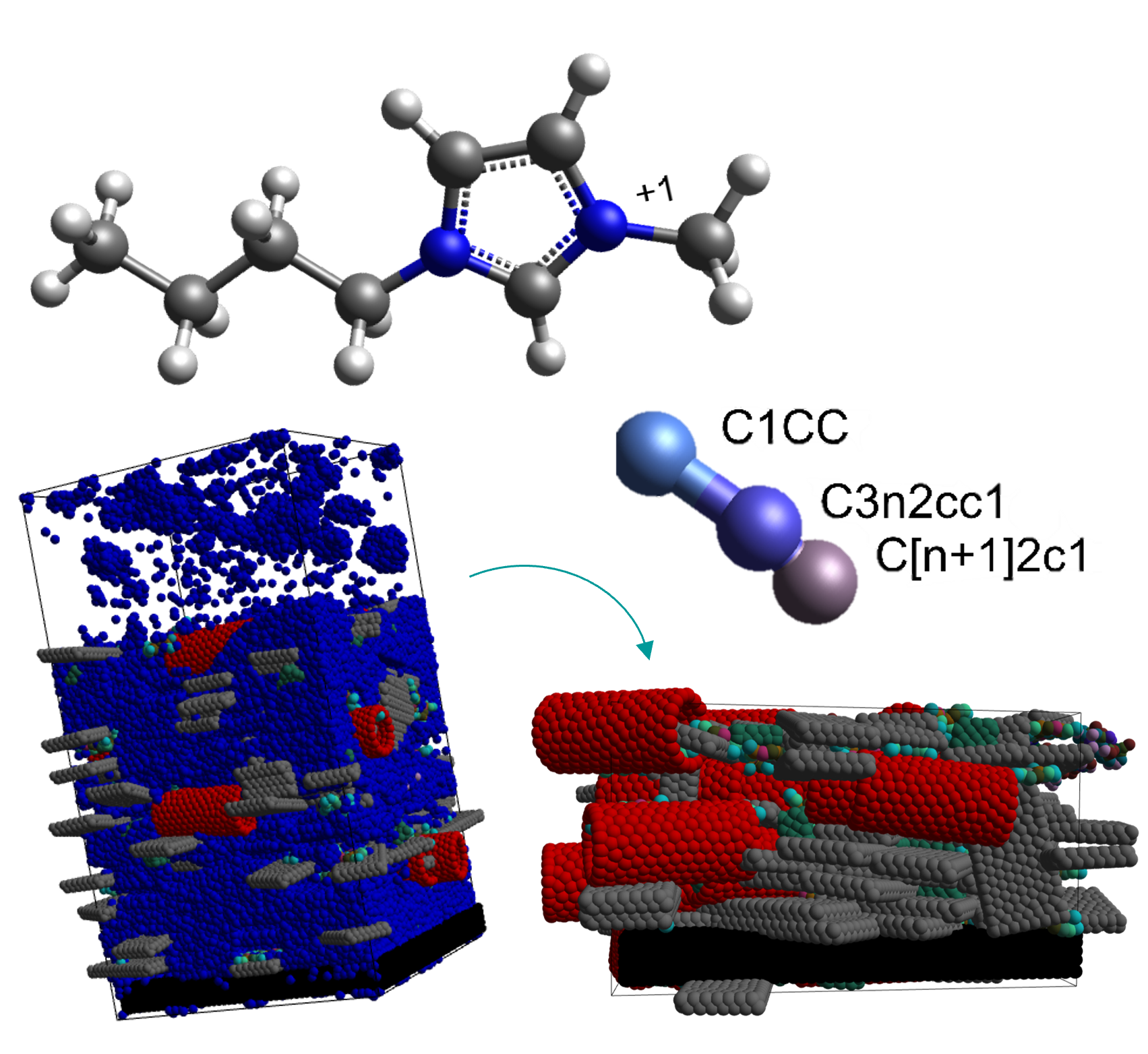

Likewise, the charge of molecules is critical for the accuracy of subsequent Dissipative Particle Dynamics (DPD) simulations. However, this fundamentally important characteristic is often overlooked by users – even experts – leading to inaccurate results or unstable DPD simulations. And even if you consider doing so, to date incorporating the charge of molecules into the parametrization process required a tedious and error-prone manual modification of the Automated Fragmentation Parametrization (AFP).

With the release of Simcenter Culgi 2311, we enabled you to leverage AFP with the fully automatic computation of interaction parameters for DPD from atomistic electron distributions. This brought down the preparation step of DPD parametrization from days to minutes for huge molecules and even down to seconds for smaller-sized molecules. With the release of Simcenter Culgi 2405, we are now expanding AFP with the first-of-its-kind universal methodology to automatically perform the necessary parameterization, including molecule charges.

The new automated management of charged molecules requires zero user intervention and hence elevates the existing AFP method and, ultimately, your productivity to another level. The automation of charge assignment will check for you that atoms are properly balanced before doing any calculations, and if a charge is missing, it is automatically assigned.

At the same time, the extended AFP immediately leads to significantly improved property prediction accuracy of DPD simulations for almost any application: whether in the battery industry, for construction materials, glass, and ceramics, Catalysts & Zeolites charged molecules are omnipresent and their consideration to gather accurate predictions has become faster and easier than ever with Simcenter Culgi 2405.

Speed up coarse-grained model preparation time up to 80%

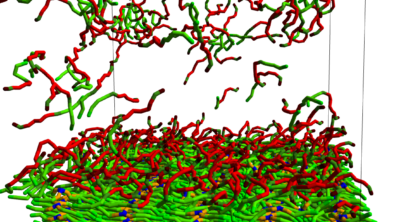

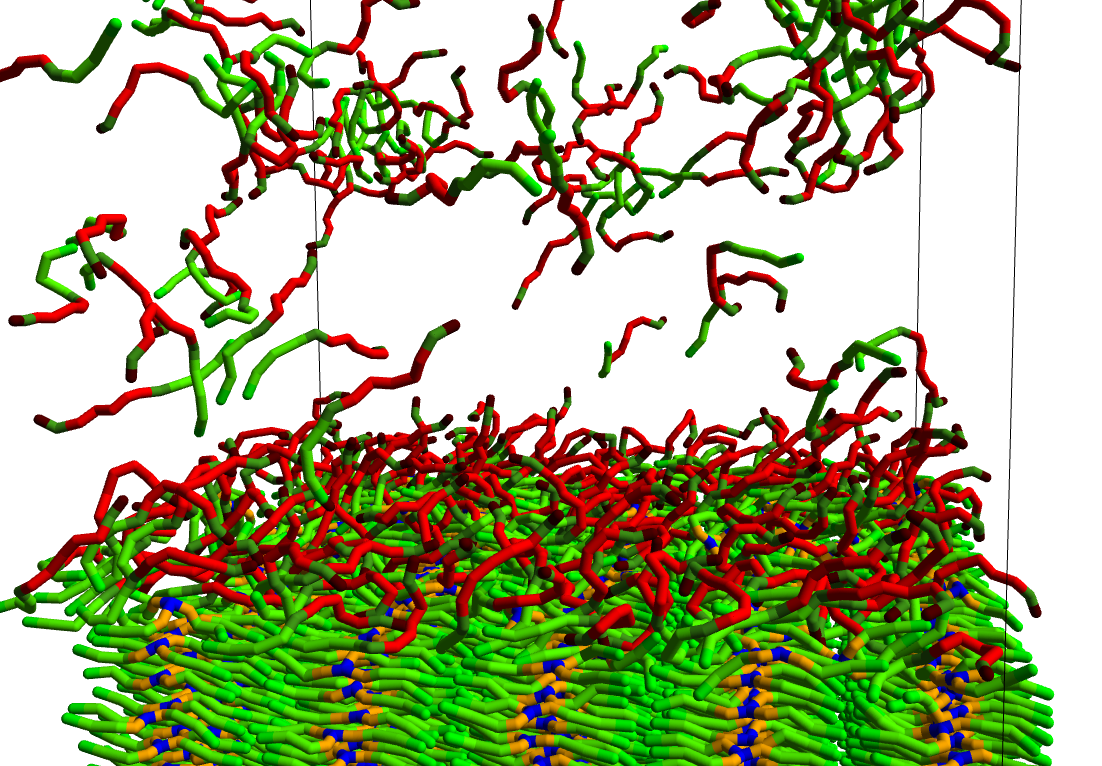

As outlined above the DPD or coarse-grained method enables the assessment of chemical system performance for many applications. However, the current state-of-the-art coarse-grained force-field framework to describe inter-molecule interactions is limited to repulsive forces. It, therefore, cannot properly model multiphase systems having limited the range of applications to liquid systems.

With Simcenter Culgi 2405 we are introducing the unique proprietary Cubic potential support for DPD simulations. This all-new proprietary cubic potential is integrating a Lennard-Jones-like attractive well for Dissipative Particle Dynamics simulations. By these means, it extends the traditional repulsive potential with an attractive branch and hence expands the modeling of multiphase systems from liquid and gaseous only to any system that alongside may include solid states. As such, the new potential also enables the correct prediction of all relevant phase transitions solid/liquid, liquid/gas, solid/gas within a single simulation. As another benefit, the Cubic potential also removes the dependency of the parameterization on the temperature: while classic DPD requires one parameterization set per temperature, the Cubic potential is offering one parameterization across all temperatures, significantly reducing the parametrization effort.

This inclusion of all phase states and phase transitions in one simulation opens up the field to a wide range of new applications across all industries, like e.g. the assessment of detergent performance at various temperatures in washing machines.

Stay integrated

Stay connected with Teamcenter Share

As traditional offices with co-located teams become rarer and teams are dispersed locally and even globally, collaboration within companies has significantly evolved and relies more and more on efficient data sharing. Being able to easily access and exchange data online is paramount for efficient work.

With Simcenter Culgi 2405, we are adding the possibility to use Teamcenter Share via the user interface to increase and facilitate collaboration between people and across all products in the Siemens Xcelerator portfolio. Teamcenter Share helps you collaborate on design and engineering projects in the cloud. It offers a rich set of capabilities designed to address your collaboration needs, enabling you to collaborate with colleagues, partners, and customers; instantly, securely, and easily.

Teamcenter share lets you collaborate seamlessly across multiple domains and products, unite teams and customers around a single source of truth, and access and share data from anywhere at any time, now also from within Simcenter Culgi.

These are just a few highlights in Simcenter Culgi 2405. Those features will enable you to design better products faster than ever, turning today’s engineering complexity into a competitive advantage.