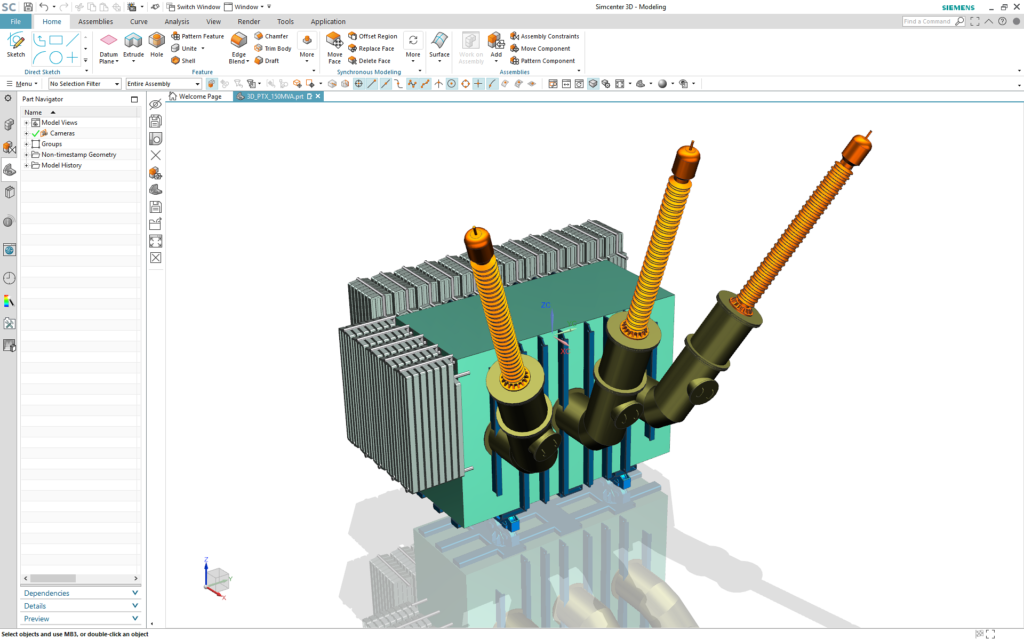

Simcenter 3D 2020.1 – Explore What’s New in Low Frequency Electromagnetics

Let’s dive a little deeper into the new capabilities available for low frequency electromagnetics in Simcenter 3D 2020.1. These enhancements offer new and improved Multidiscipline Integrations and Faster CAE Processes, which are just two of Simcenter 3D’s differentiating strengths.

Multidiscipline Integration

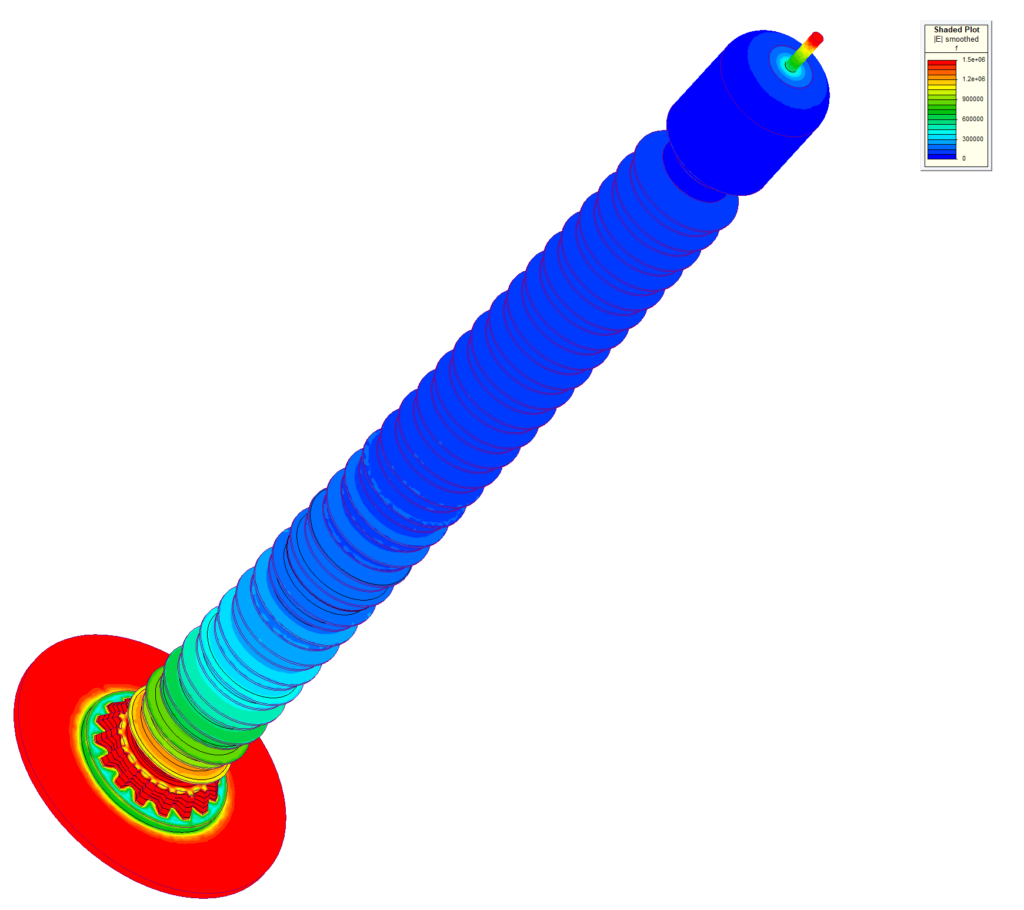

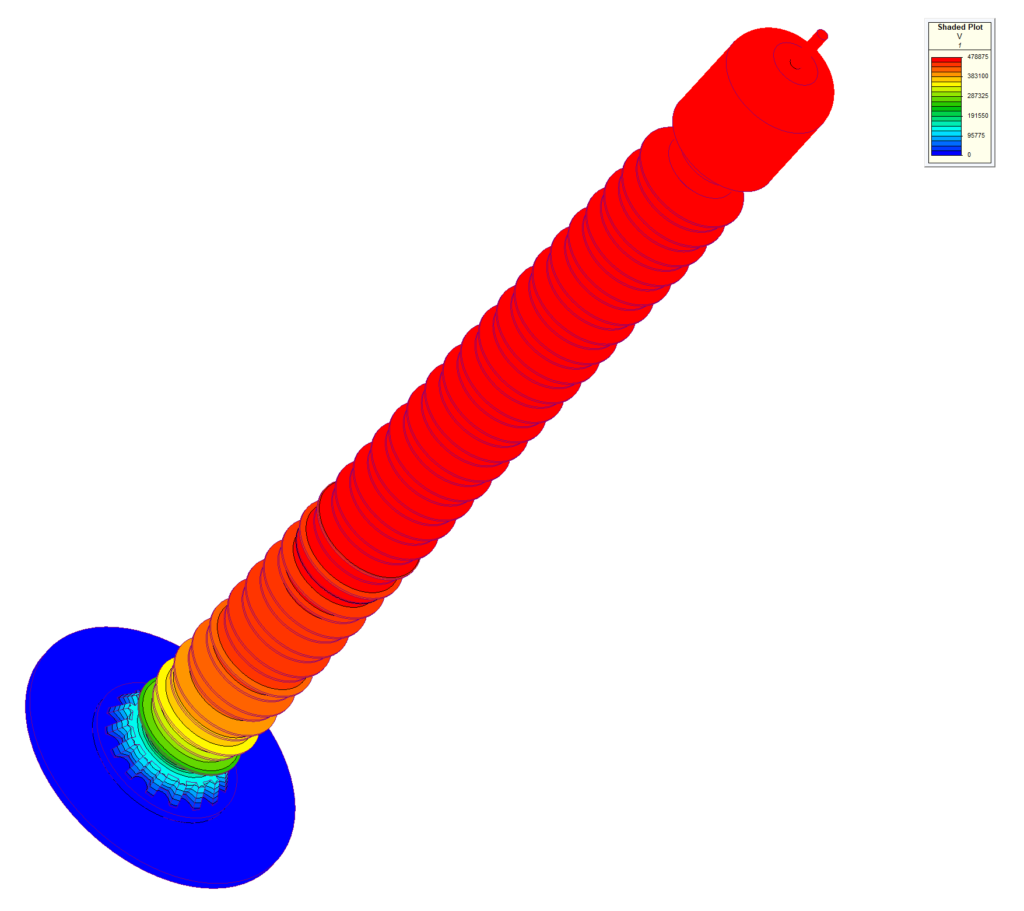

Electric Fields

Many types of electromagnetic devices require an electric field solution. Specifically, these are engineering problems for which the effects of magnetic fields may be ignored or should be analyzed separately.

To address this, we have added an electric field solver to Simcenter 3D Low Frequency Electromagnetics. As a result, this new simulation domain expands the supported range of applications to include insulation systems, high voltage components, surge arrestors, bus bars, cables, and many more.

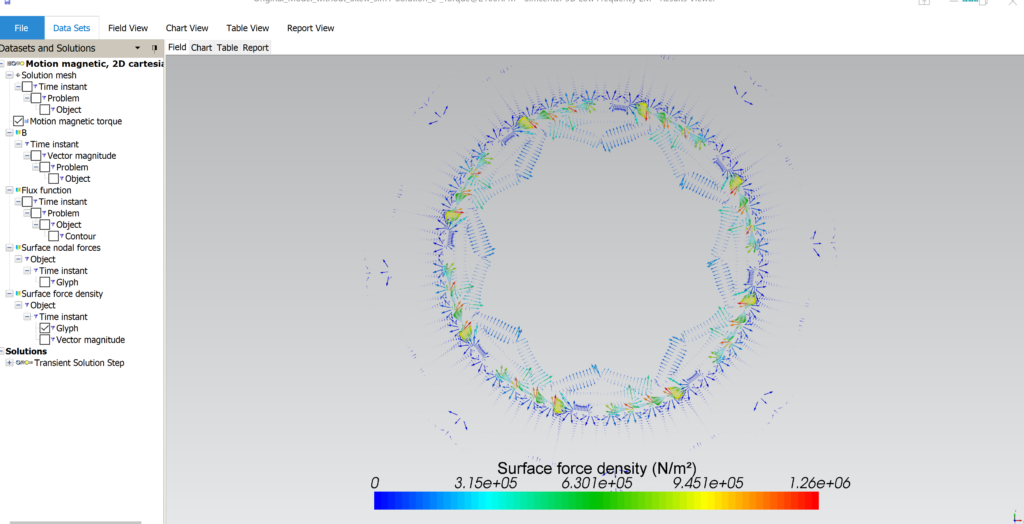

Noise and Vibration

Ensuring structural integrity and evaluating the noise and vibration levels from electromagnetic sources can be difficult. Most important to note, this is a multiphysics problem which requires time domain force data.

Therefore, we have added force density and nodal force distribution calculations to identify potential “hot spots” for stress. In addition, it can help ensure structural integrity during early stages of design. (Likewise for the recently release Simcenter MAGNET and Motorsolve 2019.1)

Improving Coupled Thermal

Electromechanical components require thermal management, whether it be a passive or active cooling strategy. For instance, the ambient temperature, surrounding fluids and dissipation rate all easily influence electromagnetic performance.

As a result, failing to design with coupled electromagnetic-thermal simulations can lead to vastly inaccurate predictions and catastrophes such as demagnetization or destruction.

For this reason, the coupled electromagnetic-thermal simulations have been improved in two specific areas to provide all the analysis capabilities required to avoid such consequences:

- First, full transient electromagnetic-transient thermal FEA, in order to understand the changing performance of electromechanical devices in operation

- Second, the average rate of heat transfer between the solid surfaces and surrounding fluid can be determined

Additionally, there is a new coupled electric field-thermal simulation to study effects such as the temperature rise due to lossy dielectrics.

Faster CAE Processes

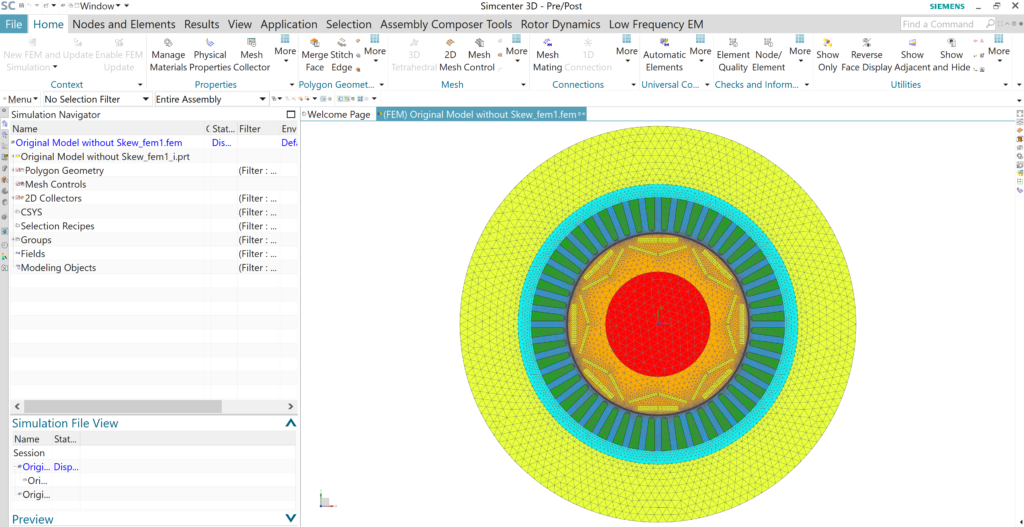

Smart Mesher Adaptivity

It’s hard to have confidence in your simulation solution without a good mesh. However, identifying the areas which require a finer discretization can be difficult and a little bit tedious.

The smart mesher adaptivity now part of Simcenter 3D Low Frequency Electromagnetics can automatically identify the areas of the mesh most in need of improvement. There are two refinement options available to select from:

- increasing the number of elements

- increasing the polynomial order

Thorough Control with Object-Level Parameters

Moving from initial concept to final high fidelity design verification is a multi-step process. Moreover, each step on the path might require examining different critical performance criteria and replicating changing or different operating conditions. Or it may also include making miniscule to drastic changes to the model and excitation.

Object-level parameters allow for these diverse requirements to be explored by giving the user control to specify conditions, such as:

- Which hysteresis method to utilize

- Include or omit eddy currents

- Include or omit remagnetization and demagnetization of permanent magnets

- Average power loss start and end time

- Mesh polynomial order