From noisy ship cabins to restful nights: tackling noise and vibrations for smoother sailing

Have you ever tried sleeping on a ferry? I often travel to Morocco with my family. For those who aren’t familiar, Morocco is the westernmost country in North Africa, just across the Mediterranean from Europe. To get there, we take a ferry from one of the ports in Spain. Depending on where we depart from, the journey can take up to eight hours. We usually choose the night ferry, which allows us to sleep in a cabin.

During our most recent trip, something really stood out—the comfort. We slept soundly through the night, almost as if we were at home, barely noticing any noise or vibrations. It was a wonderful experience. The ferry we were on was new, and that made all the difference. In previous travels, however, the story was quite different. The deep, low-frequency vibrations from the ship’s engine used to shake us, making sleep almost impossible. We would arrive at our destination feeling exhausted.

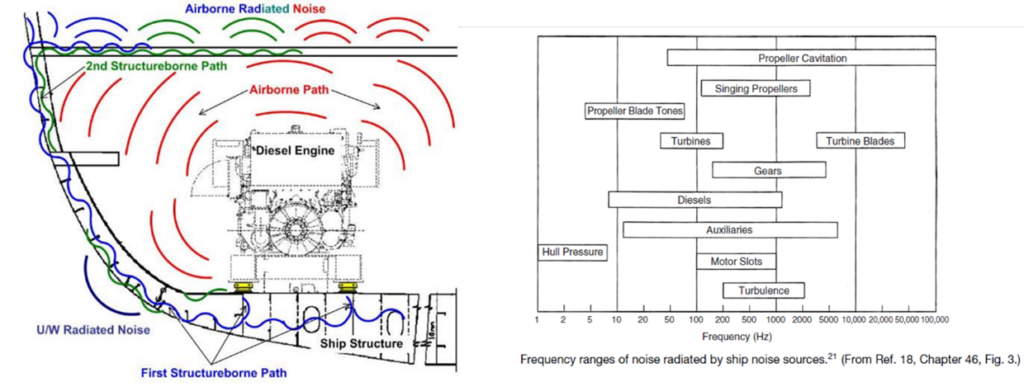

Noise and vibration on ships are more than just annoying—they can have a big impact on the safety of the crew, the durability of the ship, and even marine life. Noise can come from things like the engines, machinery, and the movement of water around the ship, while vibrations are often caused by unbalanced rotating parts. These disturbances can travel through the air or the ship’s structure, sometimes causing lasting damage.

For the crew and passengers, constant exposure to high levels of noise can lead to hearing loss, make communication difficult, and result in fatigue and stress, all of which increase the risk of accidents. Over time, vibrations can weaken the ship’s materials, loosen key parts, and lead to costly repairs.

But it’s not just the ship—underwater noise pollution can also disrupt marine animals, affecting their ability to communicate and navigate. To reduce these risks, strict regulations are in place to limit noise and vibration levels, ensuring the safety of both the crew and the environment.

Looking back at my recent trip to Morocco, I can’t help but think about the design and production journey this new ship has taken, from its initial concept through engineering and testing, all the way to its final delivery. As an engineer at heart and an Industry Specialist for Marine at Siemens Digital Industries Software, I’m very familiar with the advanced tools engineers use to build the ships of the future. It’s your lucky day: my expertise focuses on physical testing. So let me introduce you to some of these fantastic techniques.

Acquire your ship’s noise and vibration data

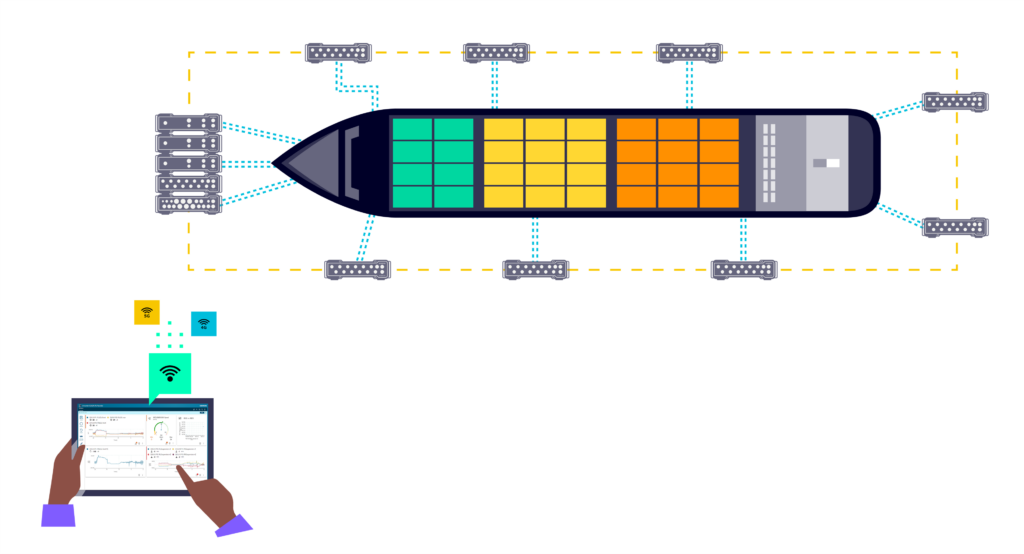

If you’ve ever traveled on a large ferry, you’ve probably been struck by its immense scale and strength. These impressive vessels can stretch over 300 meters in length and 50 meters in width, driven by one or more massive engines. As an engineer, you might wonder—how can the NVH (noise, vibration and harshness) performance of such a colossal structure be effectively verified and optimized, especially in rough seas or near the intense heat and roar of the engines?

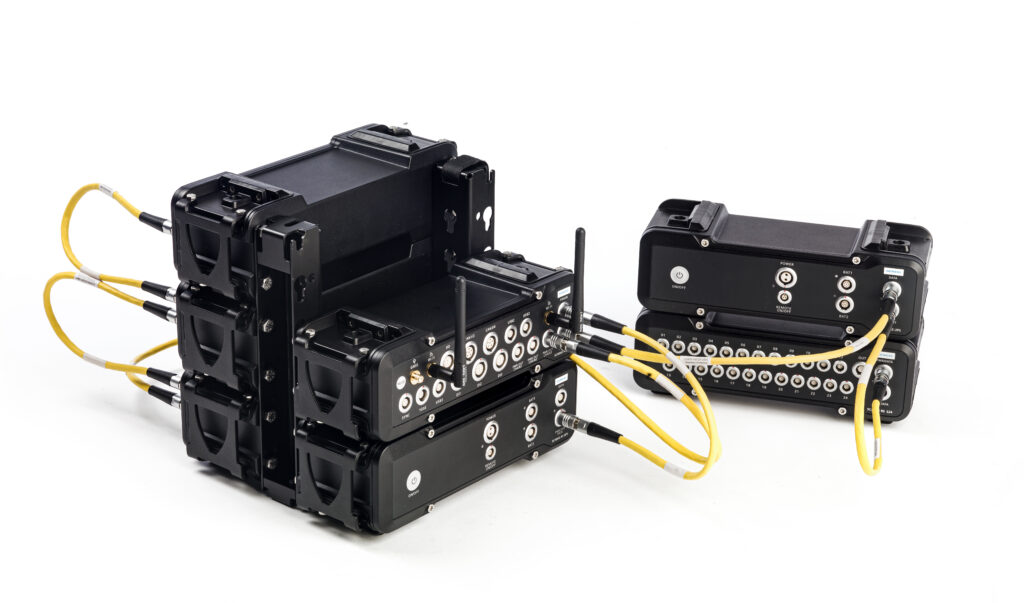

Well, let’s have a look at one of our solutions: Simcenter SCADAS RS hardware—a next-generation data acquisition system designed precisely for this challenge. Engineered for extreme conditions, it features a rugged, durable design that withstands harsh temperatures and intense vibrations. Its flexible architecture allows for seamless configuration, whether centralized or fully distributed, making it the ideal solution for acquiring NVH data on ships.

It’s a truly unique device that provides both wired and wireless access for remote control—perfect for testing near a noisy, heat-intensive ship engine. It also seamlessly integrates into automation processes by automatically uploading data for cloud computing and advanced engineering analysis, significantly enhancing test productivity.

Understand your ship’s NVH data with advanced analysis techniques

So, what can we do with all this data?

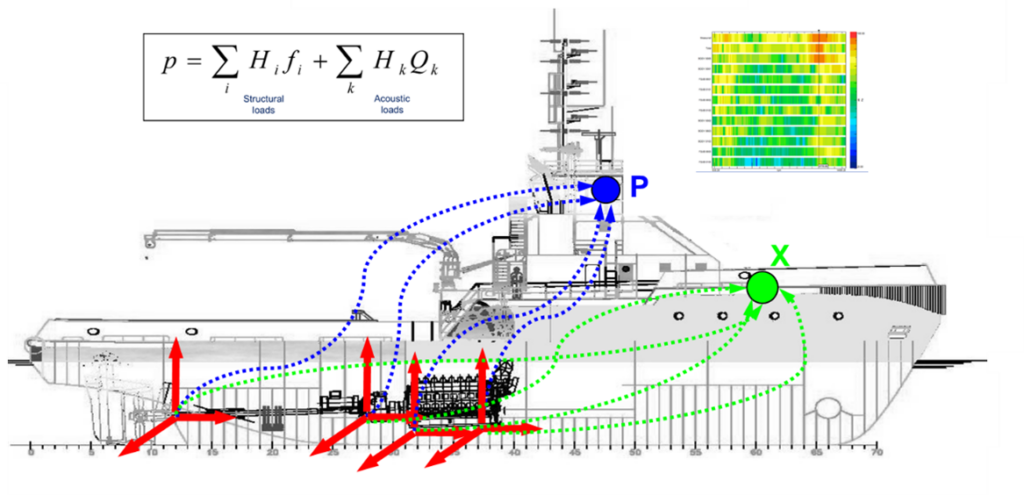

Once collected, the data undergoes further analysis to extract meaningful insights. During sea trials, for example, it helps verify whether the vessel meets construction specifications, ensuring noise and vibration levels remain within acceptable limits. In case of non-compliance, this or additional data is used to identify the root cause. This is where advanced analysis techniques, such as operational modal analysis (OMA), transfer path analysis (TPA) and torsional vibration analysis come into play.

OMA is a powerful tool for understanding a structure’s vibration behavior—such as that of a large ship—under real operational conditions. Unlike traditional modal analysis, which requires knowledge of excitation forces, OMA relies solely on output data. These insights are also invaluable for validating digital twins of the ship, enhancing predictive accuracy.

Another technique I find particularly fascinating is TPA. It breaks down the ship’s noise and vibration behavior into three fundamental components: source, transfer and receiver. By analyzing these elements, engineers can pinpoint which component contributes most to the issue. TPA also serves as a foundation for more advanced methods like component-based TPA (CTPA) and virtual prototype assembly (VPA). These techniques enable engineers to predict how design changes or component performance—such as that of an engine—will affect the entire vessel by combining test data with simulation data.

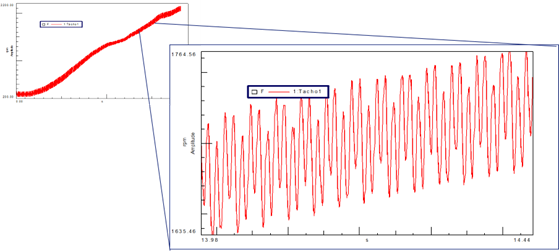

The comfort issues I mentioned earlier during my ferry crossings are often linked to torsional vibrations from the ship’s engine, which can be a major source of noise, vibration and fatigue-related problems. To analyze this in depth, precise rotational speed measurements are crucial. This is achieved using specialized encoders that generate a high number of pulses per revolution. Simcenter SCADAS HW offers state-of-the-art capabilities to interface these encoders, ensuring accurate rotational speed measurements for detailed torsional vibration analysis with Simcenter Testlab.

Curious to know more?

All these technologies and more are part of the Siemens Simcenter Testlab software suite, seamlessly integrated with Simcenter SCADAS data acquisition hardware. If you’d like to learn more about how these tools can help you tackle noise and vibration challenges on ships, I highly recommend watching our webinar and reading the following white paper.

By tackling these challenges, ship owners can make their vessels safer, more efficient and better for the environment. Properly managing noise and vibration not only protects the ship and crew but also contributes to a more sustainable and responsible maritime industry.

You might also be interested in the following:

CUSTOMER CASE STUDY

Noise Control Engineering LLC reduces noise 5 to 7 decibels in U.S. Navy aircraft carrier compartments

CUSTOMER CASE STUDY

Princess Yachts reduces the time necessary to hone acoustic performance for luxury vessels