Prevent excessive build plate distortion in additive manufacturing

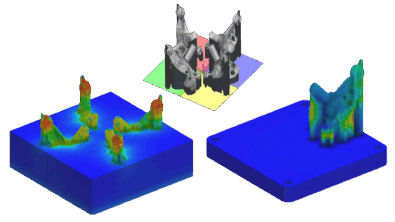

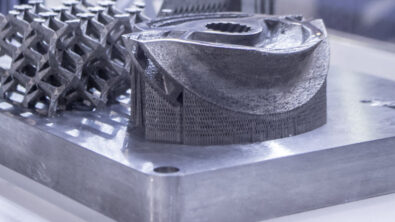

One of the unexpected effects observed after 3D printing is the excessive build plate distortion. This distortion only becomes visible after removing the build plate from the printer and can make it impossible to successfully remove finished parts from the build plate. This is because the warped build plate inhibits the ability to cleanly cut the parts of the plate.

What causes build plate distortion?

So what causes a build plate to deform? The nature of the additive manufacturing (AM) process itself is what causes the build plate deformation. Specifically, the AM powder-bed fusion processes uses very localized and high heat to fuse the metal powder as the laser travels the part path. The inherent repetitive heating and cooling of the AM process creates large residual stresses that build-up in the printed parts. These stresses get transferred into the build plate. When the print is done, engineers remove the bolts holding the build plate in place in the printer, and the residual stress in the plate also then make the build plate deform and distort, which means failed build.

How can we prevent plate distortion?

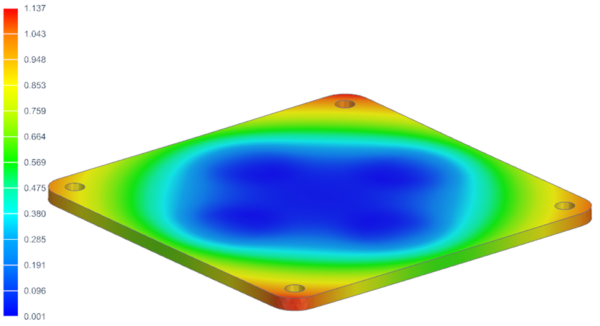

Because excessive distortion leads to a loss of a build, it is important to predict and ultimately prevent build plate distortion. Simulation of the additive manufacturing process can help engineers accurately predict how the build plate will deform. With this information, you can better set your build parameters to prevent build plate distortion.

Simulate and prevent build plate distortion with Simcenter 3D

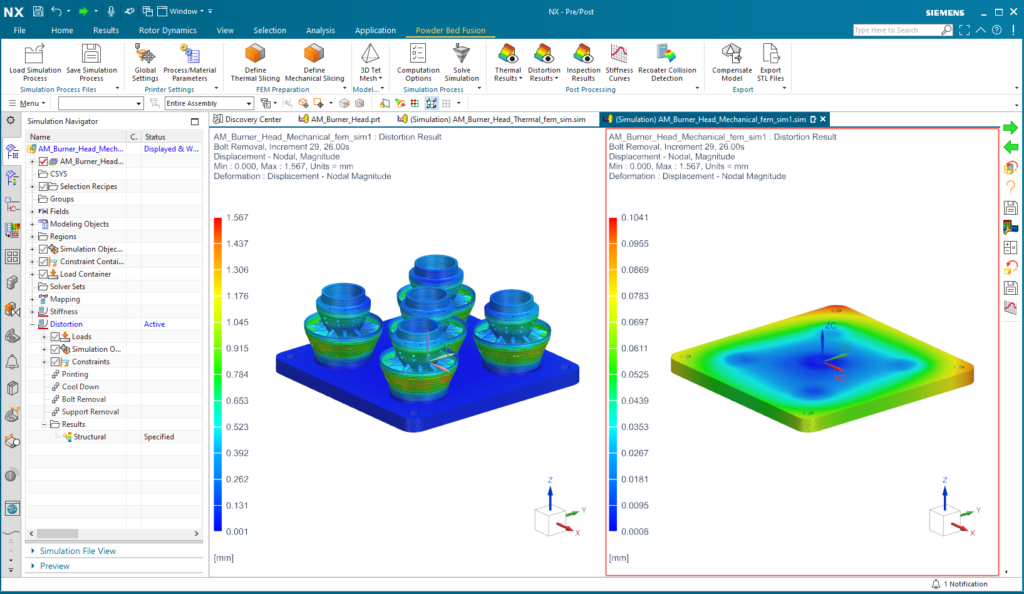

Simcenter 3D is a comprehensive and fully-integrated simulation platform that engineers across a wide range of industries use to simulate mechanical performance across many physical domains. Simcenter 3D simulates the AM build process by coupling thermo-mechanical physics phenomena, and in the latest release, we have added the ability to account for build plate distortion by simulating stresses in the build plate during the printing process.

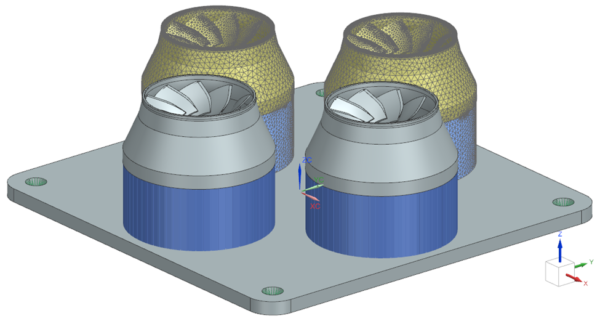

The two main contributors to build plate deformation are the stiffness of the build plate, or more directly its thickness, and the number of parts on the build plate. Simcenter 3D helps engineers select the correct thickness of the build plate or the correct number and/or distribution of parts on the plate to eliminate or minimize build plate distortion.

Engineers can now choose if they wish to include build plate flexibility in their AM model, and if they want to include a bolt-removal simulation step at the end of the process. To simulate build plate flexibility, engineers must define the thickness and the material of the build plate. Simcenter 3D automatically defines the actual shape (square or circular) and dimensions of the build plate, based on the type of printer the user selected.

Simcenter 3D then adds all loads and boundary conditions for the build plate to the AM simulation. Once the simulation is complete, the engineer can visualize, animate and evaluate the resulting distortion. If this distortion exceeds a manufacturing threshold value, part removal will become a problem. The engineer can thus decide to use a thicker build plate or remove some parts from the build and re-simulate the setup. After simulating and determining the distortions are below the part removal threshold, the engineer can move forward with a physical print that they know will print right the first time.