ISMA 2024: Celebrating the roaring success of noise and vibration innovation

Turn up the volume and get ready to rock as we celebrate the resounding triumph of ISMA 2024, where the world of noise and vibration engineering came alive with thunderous applause! This year’s event shattered all records, attracting over 700 passionate participants from 36 countries. With 384 presentations resonating through 9 parallel sessions, and an additional two days of ISMA-ISAAC-ISAMS courses that captivated 136 eager learners, ISMA 2024 set a new standard for excellence. Notably, this year’s edition also marked a historic moment as it introduced 2 Dynamic Environmental testing sessions which covered topics like Virtual Shaker testing and Multi-axis test rig design, amongst others, and broke records in terms of contributors and attendance.

And when it comes to innovation, Siemens is always at the forefront. The remarkable lineup of technological advancements presented by Siemens, particularly by the Simcenter research team from Siemens Digital Industry Software, spanned from the groundbreaking realm of executable digital twins to the impressive applications of artificial intelligence in NVH, and to pioneering measurement techniques.

Let’s dive into the conference highlights that made this symphony of success reverberate around the world of NVH engineering and beyond.

A crescendo of collaboration

ISMA 2024 witnessed an extraordinary partnership between Siemens and KU Leuven, joining forces to amplify the impact of noise and vibration innovation. As a testament to their collaboration, we are thrilled to announce the upcoming creation of the “Digital Twin for Smart and Sustainable Products Chair” in honor of KU Leuven’s 600th anniversary in 2025. This partnership promises to harmonize cutting-edge research and industry expertise to compose a future where noise and vibration engineering take center stage.

Spotlighting technological advancements

ISMA 2024 showcased a spectacular array of technological breakthroughs. Among the 20 papers presented by Siemens, three key areas stole the spotlight:

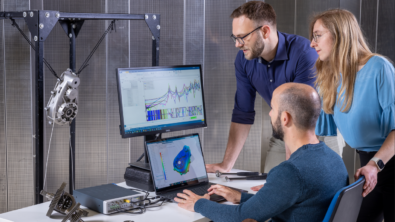

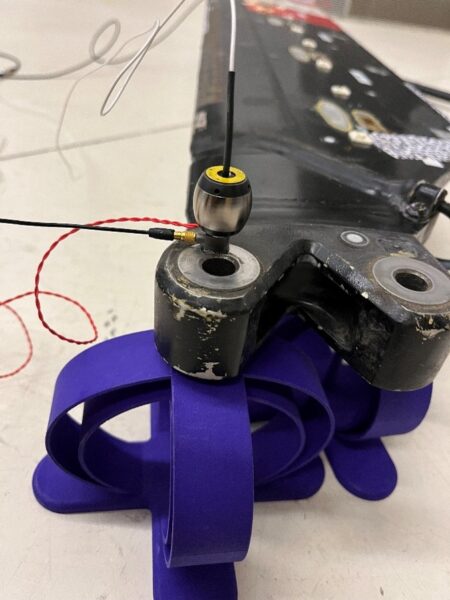

Novel dynamic testing and measurement methods:

Pushing the boundaries of traditional approaches, groundbreaking methods unveil new possibilities for accurate and precise testing in the field of noise and vibration engineering. Those methods range from excitation techniques for lightweight, low mass structures, Digital Image Correlation (DIC) vibration measurements to reconstruct sound radiation fields, video motion and modal magnification techniques and multi-axis shock and vibration control testing techniques applied to automotive battery packs.

Image: Inertial shaker for the excitation of lightweight structures

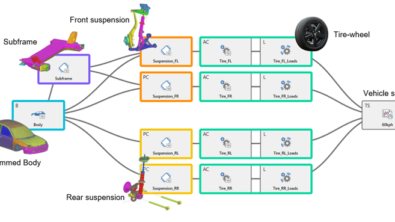

Executable digital twins

ISMA 2024 showcased the growing importance of digital twins in industry, highlighting their transformative effects and how these digital replicas provide valuable insights and open doors to improved performance and optimization. Notable highlights included advanced Model Order Reduction techniques, real-time capable NVH models for Human-in-the-Loop testing, Virtual Sensing methods to extend information across the full-field response and the introduction of a virtual shaker testing approach, enabling optimization of test setups and control parameters before conducting vibration control tests. During the conference, Siemens researchers showcased their research efforts in the domain of Executable Digital Twins, which have gained significant prominence in various industries in recent years. Their work exemplifies the growing interest and focus on this topic, demonstrating the importance of digital twins as a powerful tool for industry transformation.

Image: Executable digital twin of an automotive suspension

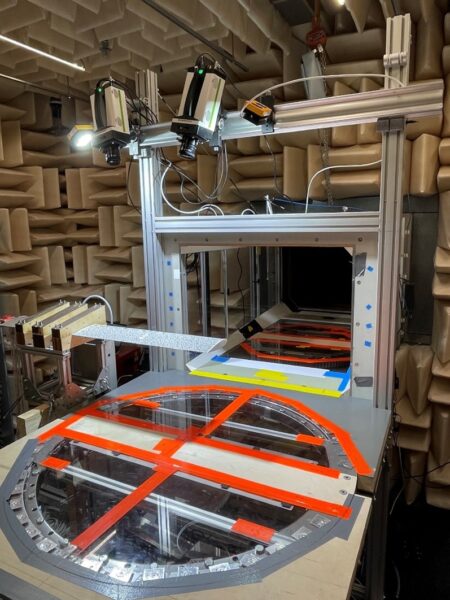

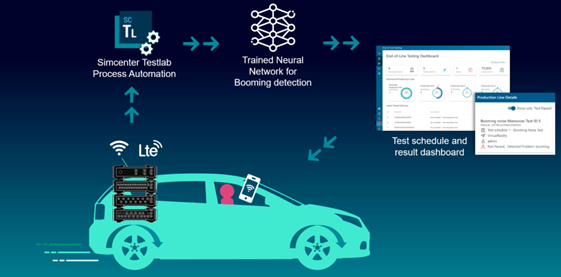

AI/ML for noise & vibration applications

ISMA 2024 showcased the incredible potential of artificial intelligence (AI) and machine learning (ML) in tackling noise and vibration challenges. From predictive maintenance to automated modal analysis, these technologies are revolutionizing how engineers analyze, interpret, and mitigate noise and vibration issues. The conference featured cutting-edge research and real-world applications that demonstrated the power of AI and ML in various application domains including full vehicle NVH end-of-line testing, clustering of additive manufactured components, automated modal analysis for structural dynamics, sensor anomaly detection in noise and vibration testing and early-stage assessment of battery NVH performance.

Image: AI-assisted vehicle end of line testing

An extraordinary gathering

ISMA 2024 was more than just a conference; it was an extraordinary gathering of brilliant minds, passionate about advancing the field of noise and vibration engineering. The event provided a platform for networking, collaboration, and knowledge sharing, leaving a lasting impact on the industry. Visit ISMA for more information on the conference program.

As we bid farewell to ISMA 2024, we invite you to stay tuned for future updates as we continue to push the boundaries of noise and vibration innovation together.

Remember, the world of noise and vibration never sleeps, so let’s keep the rhythm of progress alive and make some noise for the future of engineering excellence with Simcenter!