Noise Reduction for Automotive: Sometimes you just want a relaxing ride

While some drivers prefer loud vehicles, many prefer a low-noise environment in the interior, where they can relax during long road trips, talk to other passengers without raising their voice, or simply enjoy their favorite music. This is why Automotive OEMs consider interior noise reduction as an important development goal, as it can improve comfort but also safety for drivers.

What’s so noisy?

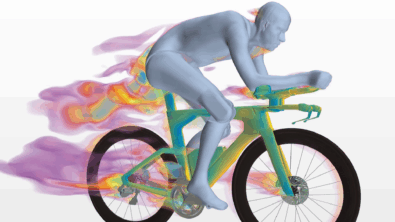

Most modern vehicles today carry low-noise powertrains, making road and wind noise the most disturbing interior noise sources. Under high speed driving conditions, wind noise becomes even more dominant. To further significantly reduce interior noise, the aerodynamic noise must be addressed!

Identifying and reducing the aerodynamically created sources around the vehicle are important in the development of a vehicle. This is, of course, not as easy as it might seem at first sight. To fully take control on the interior wind noise, it is important to map the full aero-acoustic energy flow, from the exterior source distribution generated on the exterior of the vehicle, towards the transfer of those sources towards the interior.

Testing

Because wind tunnel tests are extremely expensive, car manufactures want to get the most out of every test campaign. This places high demands on the aero-acoustic testing system in terms of efficiency and technology. Three essential requirements to achieve this are:

- Have advanced aero-acoustic testing technology in place that allows to map all aero-acoustic sources in and out of the vehicle. For this, the use of large planar microphone arrays have become widely accepted. The data of the microphone arrays, together with state-of-the-art source localization algorithms makes it possible to precisely localize the sound sources on the vehicle’s geometry. Combining this with interior noise data from artificial heads and spherical arrays, additional processing can reveal weak spots and relevant external sound sources.

- Have the results available on the spot, i.e., see the sources created around the vehicle in real-time or immediately after a measurement. Also easy interactive comparison with previous measurements is of importance. All of this needs to happen during operation of the wind tunnel.

- Have a fit for purpose (often automated) process that serves all stakeholders in the wind tunnel. This means a system that has the required ease of use for the wind tunnel operators; a system that automates repetitive processing tasks, and that provides all capabilities for the aero-acoustic specialist to look immediately at automatic results, while also having the ability to do interactive and advanced post-processing.

How to get there?

Based on these 3 pillars, Siemens, in cooperation with its partner MicrodB, has developed a highly efficient, advanced aero-acoustic wind tunnel testing solution.

Watch this video example from Mercedes-Benz.

Read all about it in the “Efficient vehicle wind tunnel testing for noise reduction” white paper and learn about:

- How to achieve efficient wind tunnel testing that provides all the needed engineering insights during a test

- The key elements for external and internal NVH measurements

- How the implementation of the testing solution can help to make the right decisions during the tests and positively impact total testing time

Read the white paper here.