Using an integrated safety approach to assess aircraft crashworthiness

There’s no question that safety and performance are paramount in the aerospace and defense industry. Verification and certification processes are critical throughout the full aircraft system lifecycle. Companies today are required to satisfy an increasing number of safety requirements while also delivering products on time and within budget. To make this possible, organizations need to better integrate design and certification teams by building a verification and certification digital twin to manage analyses data and test article configurations, while maintaining the thread from requirements to verification artifacts.

Advancements in urban air mobility illustrate the importance of this. The successful implementation of the UAM market will require emergency landing concepts that address real-world safety expectations. Revolutionary eVTOL designs force the authorities to rethink the existing emergency landing regulations. An integrated safety approach based on the digital twin methodology provides an interesting solution for eVTOL crashworthiness optimization.

FAA and new safety concept for eVTOL crashworthiness

As presented in the eVTOL Crashworthiness Workshop #2 of the FAA in October 2020, many new types of eVTOLs might not fit typical aircraft categories of the current regulations. For example, the emergency landing conditions of speed, acceleration and angle are based on historical data of certain traditional technologies. New types of aircraft would need new analyses of the emergency landing conditions that also could be based on a new kind of redundant systems that reduce the landing speed. Aviation authorities would be open to propose new safety concepts that go beyond the traditional requirements of the 14 CFR *.561 and *.562 as long as the main principals of the regulations are preserved.

The road to a new level of eVTOL crashworthiness

The occupant safety must be an integral part of the overall technical and management processes associated with the design, development and operation of UAM systems. By using an integrated safety approach, the whole aircraft is considered in the safety performance assessment. As such, the overall safety performance results can differentiate from the sum of the standardized subsystems evaluations according to the current regulation. Within the approach, all key criteria will need to be addressed such as maintainable survivable volume, minimization of the deceleration loads to occupants, maintain egress paths, and the evaluation of the retention items of mass. Today, the usage of advanced digital system representations allows companies to perform these safety assessments at a much lower cost than physical testing. The National Institute of Aerospace Research (NIAR) has been studying this integrated safety approach for aerospace in recent years.

Digital twin capabilities for the integrated safety approach

Recently, Dr. Gerardo Olivares (Director, Advanced Virtual Engineering and Testing Laboratories, NIAR) and I presented research results in this on-demand webinar.

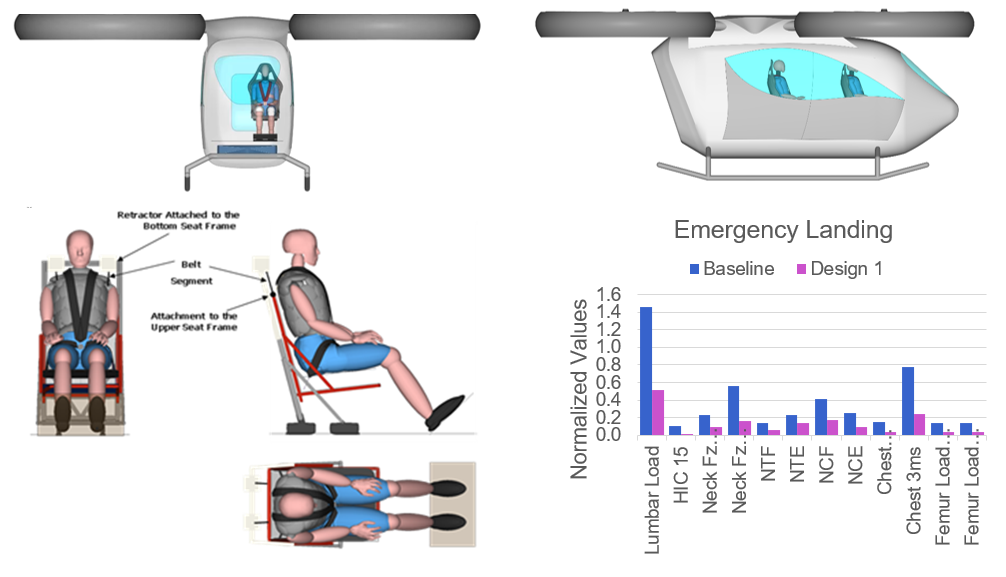

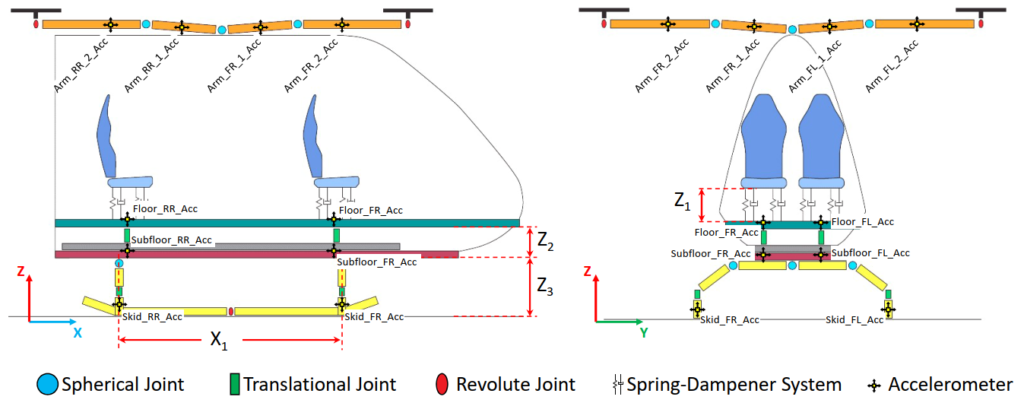

In the integrated safety development process, the concept development starts from defining the emergency landing conditions and the architecture of the aircraft energy absorbing capacity of the subsystems and structures. The integrated safety is modeled using Simcenter Madymo. Due to the efficient multibody simulation methodology and smart optimization tools as HEEDS, this approach allows to explore large and complex design spaces without the need of tuning optimization algorithms nor high number of CPUs.

The simulation methodology of Simcenter Madymo has evaluated over 40 years, and it includes validated models of Anthropomorphic Test Devices (ATD’s, also known as crash test dummies) and human models with controlled muscle activity. All modern safety restraint functionalities that can be seen in the aerospace and automotive industry can be included in the model. This includes, for example, smart airbags, multiple load limiting on seat belt, belt pretensioners and more.

After the concept layout of the energy absorbing architecture, more detailed methodologies are used to define the subsystem detailed design. To prove the quality of the hardware, only tests on the component level were used to validate the hardware with respect to the numerical targets.

Conclusion

At all times the fast Simcenter Madymo system model could be used to monitor the safety system performance based on the latest component or subsystem data. By doing so, NIAR developed an aircraft seat that passed the requirements in the first test after only six months of development. Furthermore, the test results matched very well to the predicted performance by simulation, as such they prove the maturity of the methodology and the tool set.